It’s quite frustrating to deal with limescale buildup in household appliances such as hot water tanks, washing machines, and kettles, especially in areas where the water is hard with high calcium content. Using vinegar or a special descaler helps remove the rock-hard deposits and restore the functionality of these appliances.

This is a nuisance in households, and it’s an expensive problem in thermal power stations. In thermal power stations, which generate electricity, the buildup of limescale is known as fouling. Heat exchangers are particularly prone to limescale buildup, which significantly reduces the efficiency of the systems.

Just one-millimetre thick layer of limescale in the heat exchanger’s pipes reduces the efficiency of electricity production by approximately 1.5%.

A research team from ETH Zurich and the University of California, Berkeley, has developed a special limescale-repellent coating that has microscopically small ridges preventing the adhesion of limescale crystals.

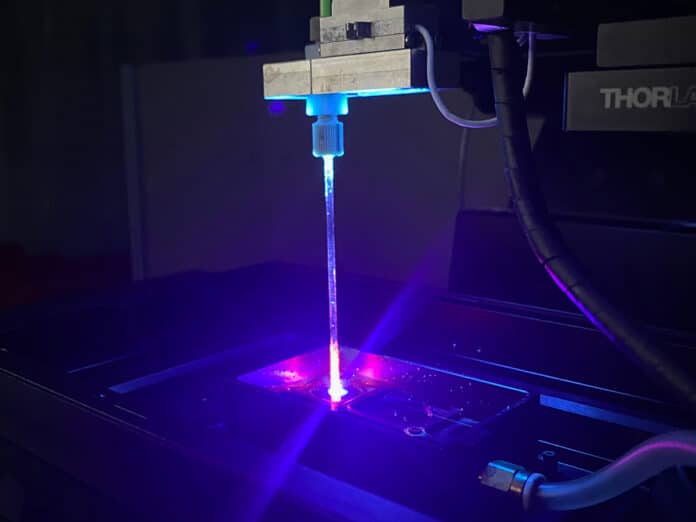

The development of limescale-repellent surfaces has not been widely researched. Therefore, the team, led by former ETH Professor Thomas Schutzius, closely examined the interactions among individual growing limescale crystals, the surrounding water flow, and the surface at the microscopic level to see how the crystals deposit and adhere in dynamic aqueous environments.

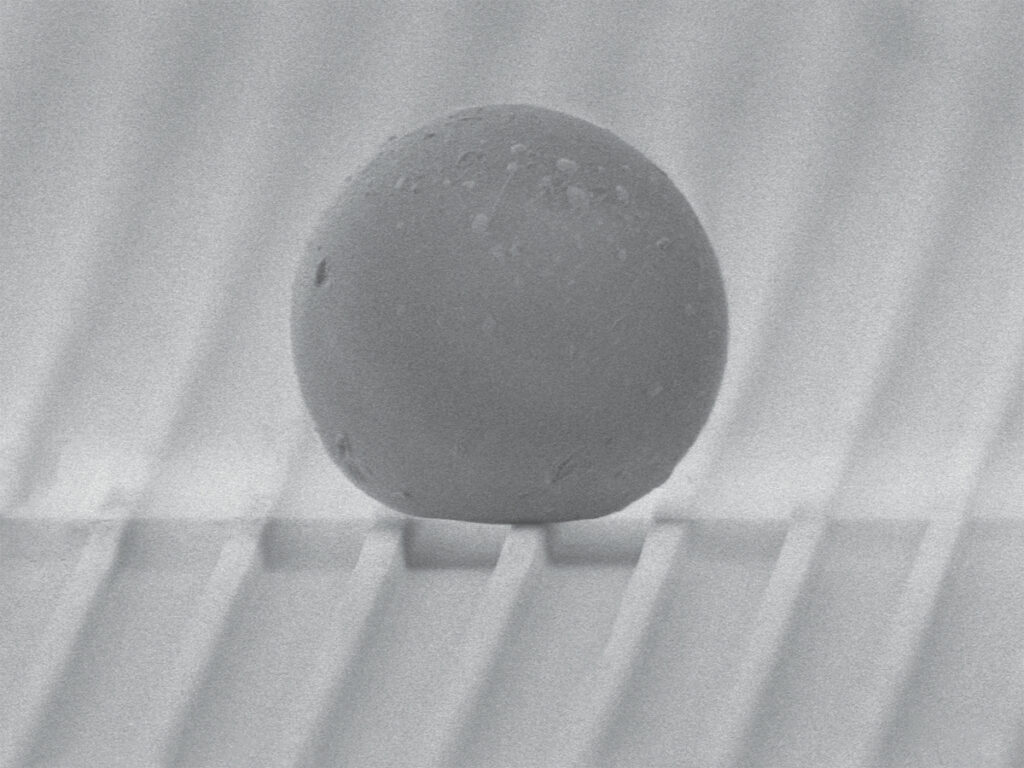

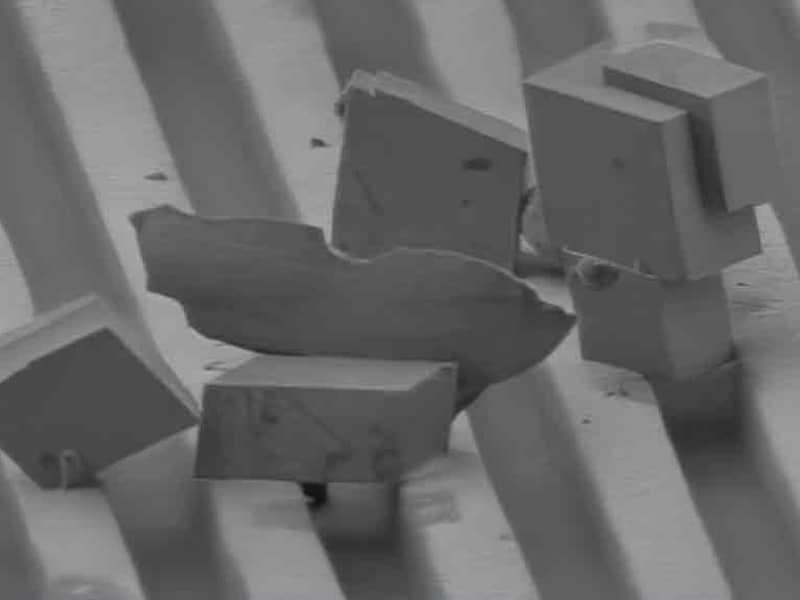

The researchers conducted experiments with different polymer contents and found that lower polymer content and higher water content resulted in less adhesion of calcium carbonate crystals. They created a surface with tiny ridges inspired by the ridges on a shark’s skin. Tests using model particles made of polystyrene demonstrated that the surface ridges needed to be smaller than the particles deposited on them to reduce the adhesive force.

“We varied the material’s surface structure to achieve the greatest efficiency, then carried out the crystal experiments with this optimum structure size,” says Schutzius’ doctoral student Julian Schmid.

The team’s experiments showed the hydrogel coating is highly effective in removing limescale crystals. When water was allowed to flow across the hydrogel-coated surface, which had previously grown limescale crystals with a size of around 10 micrometers, up to 98% of the crystals were removed.

The researchers behind the new coating solution claim that it is both eco-friendly and more efficient than existing approaches to descaling, some of which use toxic and aggressive chemicals. They also suggest that the hydrogel they’ve developed is biocompatible and environmentally friendly, making it a more sustainable option. Additionally, the technology behind the solution is scalable and can be applied in several ways already used in the industry.

Interestingly, the researchers have opted not to apply for a patent for their development. Instead, they have decided to publish their findings in a scientific journal so that other interested parties can use and further develop the novel coating.

Journal reference:

- Schmid J, Armstrong T, Dickhardt FJ, Rameez Iqbal SK, Schutzius TM. Imparting scalephobicity with rational microtexturing of soft materials. Science Advances, 2023. DOI: 10.1126/sciadv.adj032