Engineers at the College of Engineering at Georgia Tech have designed a new process that makes recovering carbon dioxide from the carbon capture process less energy-intensive and more economical. The carbon dioxide removed from the air is converted into useful raw material that could be used for new plastics, chemicals, or fuels.

Scientists are addressing the issue of reducing greenhouse gases in the atmosphere, especially as global temperatures continue to rise. Different approaches are being explored to address this problem, such as using alternate energy sources like solar and wind to prevent the release of carbon dioxide.

Another option being researched is carbon capture, which involves capturing the carbon dioxide that is already present in the atmosphere. This process can be applied at facilities where CO2 is produced as a byproduct or even directly to grab CO2 molecules from the air through a method called Direct Air Capture (DAC).

This process typically uses a material or chemical with an affinity to CO2, but the systems used for carbon capture are fairly complex and expensive to build and deploy, which can be a challenge. It can also be difficult to achieve high-efficiency rates, as current systems only capture about half of the CO2 they process.

One of the chemical approaches to DAC involves the use of potassium hydroxide (KOH). This liquid alkaline solution has the ability to turn the carbon dioxide molecules into more complex compounds known as carbonates. However, the process of separating carbon dioxide from carbonates is both energy-intensive and expensive to execute, whether for storage or to make products from it.

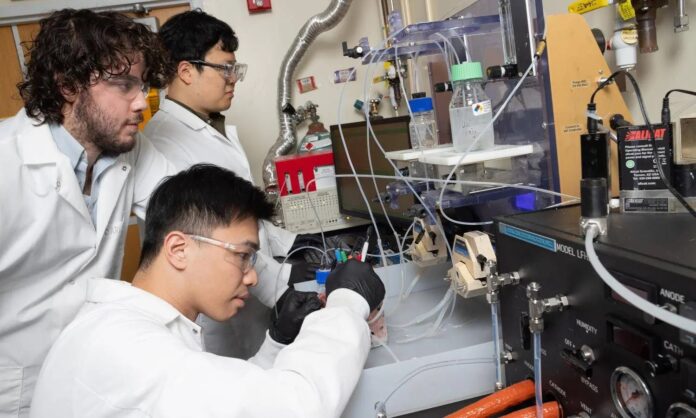

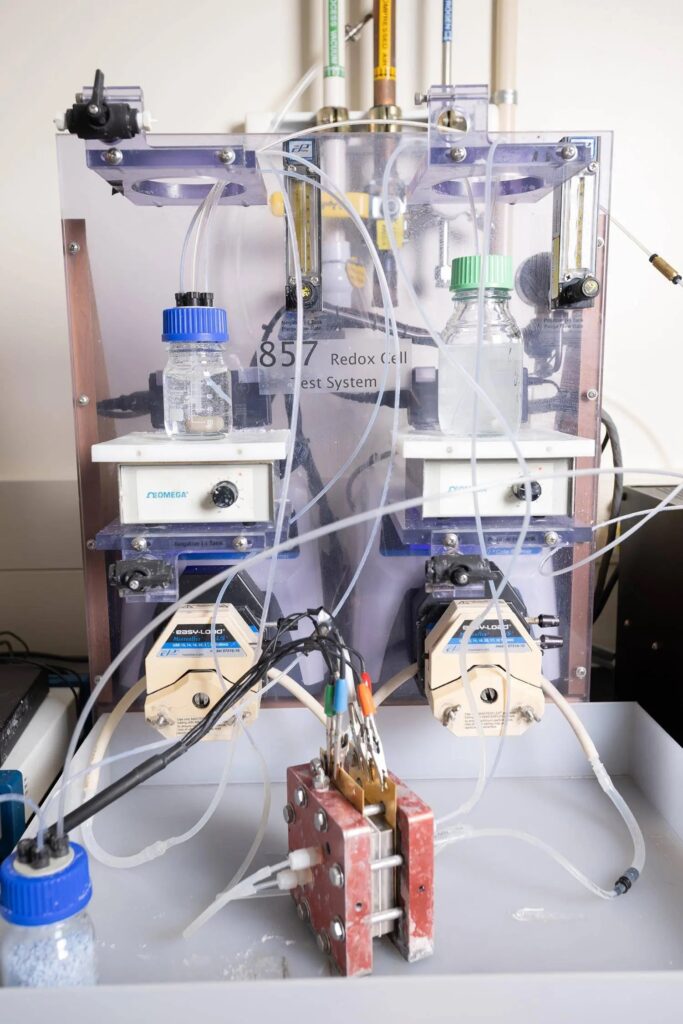

Researchers have collaborated with a lab at the Korea Advanced Institute of Science and Technology to create a new nickel-based catalyst. When coupled with a bipolar membrane, this catalyst can extract CO2 from bicarbonates and convert it into carbon monoxide (CO) gas.

“We’re capturing the CO2 into carbonates, which is a spontaneous process and doesn’t take much energy. And we’re getting rid of the desorption process and all of that energy expenditure,” Ph.D. student Carlos Fernández said. “We save about 90% of the energy in the capture process and about 50% of the capital cost.”

According to the researchers their setup also is extremely efficient at using all of the CO2 that moves through the reactor. This is vastly better than systems that keep the carbon dioxide as a gas throughout the separation process.

“We’re twice as efficient. Our CO2 utilization efficiency is almost 70%, but the gas-phase system is 35%,” postdoctoral scholar Hakhyeon Song said. “The maximum CO2 utilization in gas-based systems is theoretically 50%. But in our case, our maximum efficiency is 100%.”

The latest advancements in carbon capture have the potential to revolutionize our approach to tackling climate change. The team’s new catalyst is a game-changer, as it can work efficiently in an acidic environment, which has been a significant limitation of previous systems.

By suppressing competing reactions, this nickel-based catalyst opens up a world of possibilities for producing new useful products from CO2, which could be linked to existing chemical processes.

The applications of this technology are limitless, especially the possibility of linking it to existing chemical processes and producing new useful products. The idea of using CO as the basis for plastics, industrial chemicals such as ethylene, and even jet fuel sounds promising.

“That’s why we chose CO,” Fernández said. “Other products are harder to make, and CO is a good base for any carbon chemical. You can go from CO to almost anything through thermochemical processes.”

Journal reference:

- Hakhyeon Song, Carlos A. Fernandez, Hyeonuk Choi, Po-Wei Huang, Jihun Oh, and Marta C. Hatzell. Integrated carbon capture and CO production from bicarbonates through bipolar membrane electrolysis. Energy and Environmental Science, 2024; DOI: 10.1039/D4EE00048J