Glass is a unique material. Researchers are sure that its atoms are all jumbled up, which could be a liquid or a solid. It’s something in between. Heating materials create this unique stuff until they melt and cool down quickly. This quick change doesn’t allow the atoms to organize themselves neatly like in solids. Instead, they stay messy, like in a liquid, but stuck in place and stiff, like a solid.

John Mauro, Dorothy Pate Enright Professor of Materials Science and Engineering at Penn State, said, “In many ways, Glass is a state of matter all its own. Any liquid can form a glass if it’s cooled rapidly enough. You can make Glass out of water. Physicists believe that most of the water in the universe is probably in glassy form. In movies, they use Glass made from sugars for breakable windows and dozens of glasses are made from metallic alloys. Anything liquefied can be brought into the glassy state if quenched fast enough to avoid crystallization.”

When they think of Glass, people usually imagine something like silica or soda lime silicate glass. This is the Glass used in everyday things like windows and glass dishes. It’s made by melting three primary materials: sand, soda ash, and limestone.

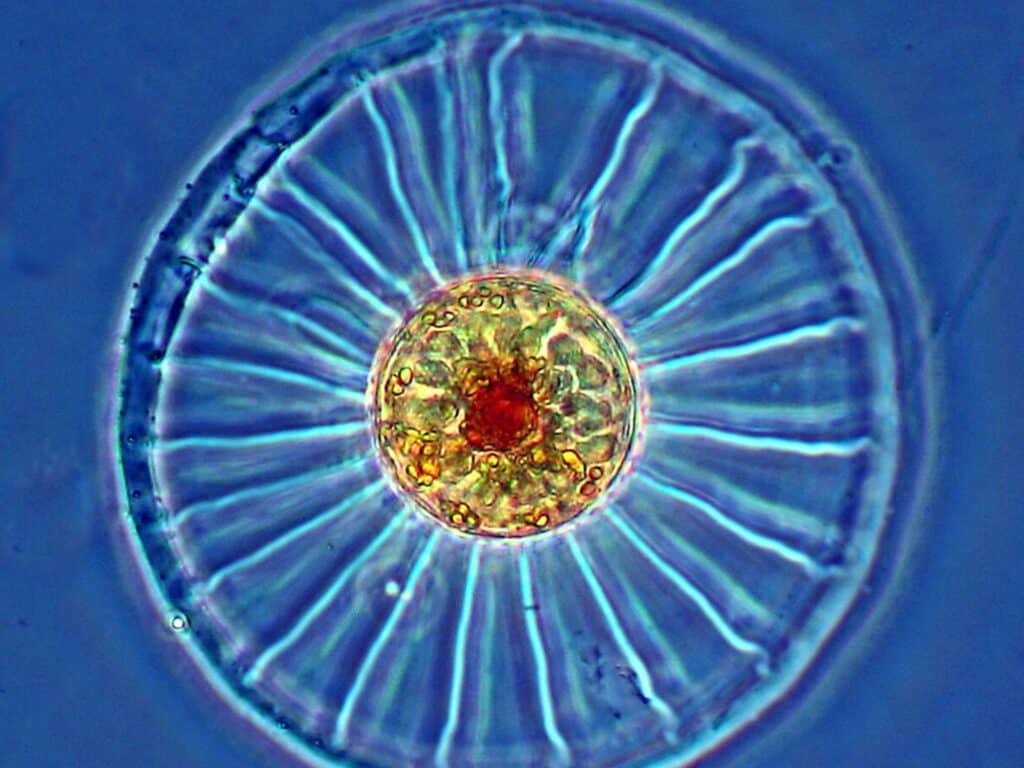

But there are many types of Glass, and people need to make more. Natural glass-like obsidian is found near volcanoes and on Mars in impact craters. Also, tiny algae called diatoms make delicate glass shells out of silica.

Mauro said, “Glass has been here far longer than we have. “Since prehistoric times, humans have been using it as a tool — and that tool continues to shape civilization today.”

Time for a Change: The recipe for regular Glass, silicate glass, has been used for thousands of years. It’s made from three common minerals found on Earth. This mixture has been the basis for Glass used in windows, jars, and cups. But now, a researcher named Mauro and his team have created a new kind of glass called LionGlass. It needs less energy to make and is more challenging than regular Glass. Unlike the old Glass, LionGlass doesn’t use the same ingredients.

Mauro has applied for a patent to sell LionGlass, named after Penn State’s mascot. The recipe is a secret until the patent is approved.

The main reason for inventing this new Glass is to reduce carbon emissions. The old glass-making process releases a greenhouse gas called carbon dioxide. This happens because of the materials used. LionGlass aims to be more eco-friendly.

The most significant carbon emissions in making Glass come from heating furnaces to extremely high temperatures, almost 2,700 degrees Fahrenheit or 1,480 Celsius. LionGlass reduces this temperature by about 300 to 400 degrees Celsius, using about 30% less energy than regular Glass.

Around the world, glass factories produce at least 86 million tons of carbon dioxide each year. LionGlass doesn’t use carbon-containing materials; its lower melting point means it can cut this carbon pollution in half.

“Our aim is to make glass-making better for the environment now and in the future,” Mauro explained. “LionGlass does this in two ways: no carbon materials and lower melting temperatures.”

At Penn State, researchers have created a groundbreaking glass called LionGlass, which is ten times stronger and has half the carbon footprint compared to regular glass. LionGlass is gaining attention from global companies and undergoing real-world testing.

Regular glass is known for its chaotic atomic structure, somewhere between a liquid and a solid. LionGlass is different and doesn’t use the traditional ingredients found in everyday glass. It aims to reduce carbon emissions from glass manufacturing, a significant source of CO2. By lowering the melting temperature, LionGlass can cut energy use by about 30%.

Glass production globally produces a whopping 86 million tons of CO2 yearly. LionGlass, with its eco-friendly approach, promises to halve this carbon footprint. The goal is to make glass production sustainable. Researchers are also working on understanding glass’s complex atomic structure to create even better drinks in the future.

According to John Mauro, a materials science and engineering professor at Penn State, glass plays a crucial role in addressing global challenges like the environment, renewable energy, energy efficiency, healthcare, and urban development.

The team behind LionGlass, a revolutionary glass, is now collaborating with industry partners to explore its real-world applications. LionGlass isn’t just one type of glass; it’s a whole family of glass compositions. They are testing various compositions within this family to discover their properties and potential applications.

Nick Clark, a postdoctoral fellow on the team, is amazed at LionGlass’s strength. It’s not only environmentally friendly but also much stronger than regular glass. Some LionGlass compositions are so intense that they don’t crack even under heavy pressure from a scientific instrument. The team is still in the discovery phase, finding out what LionGlass can do and how it can positively impact various industries.

An Incredible Discovery: LionGlass, a new type of glass, is incredibly tough. Researcher Nick Clark found that LionGlass is at least ten times more resistant to cracking than regular glass, which usually breaks under a load of about 0.1 kilograms of force. They have yet to find the limits of LionGlass’s strength because it withstood the maximum load allowed by their testing equipment.

This discovery is significant because crack resistance indicates how well a material will perform over time. Microcracks and scratches weaken the glass, leading to failure. LionGlass’s opposition to these cracks makes it a much more substantial material.

Stronger glass can also be thinner, which is good for the environment. LionGlass has the potential to be ten times lighter than regular glass, reducing emissions during transportation.

Clark continues studying LionGlass in different environments and under various stresses, working closely with industry partners. They are testing how it reacts to chemicals, acidic environments, and physical stress to uncover more valuable properties.

Julia Chen, a Penn State undergraduate student, also conducted experiments to understand LionGlass better and plans to write her honors thesis. Working with industry has expanded their network and opened up new research opportunities.

Clark emphasized the convenience of working at Penn State, where they can develop an idea, create the glass, test it, and analyze it all in one day, thanks to the university’s resources.