Due to the invention of the printing press, the duplication of the written word was revolutionized, giving rest to tired scribes and providing access to written materials for more people. A similar breakthrough has occurred in the McKelvey School of Engineering at Washington University in St. Louis.

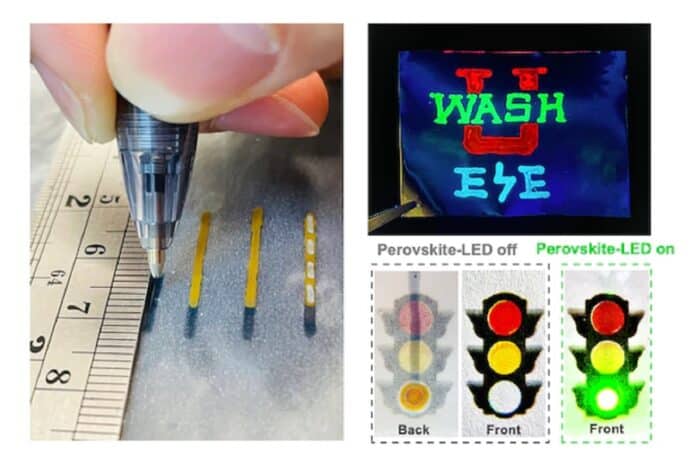

Researchers have created ink pens that allow people to handwrite flexible, elastic optoelectronic devices on everyday materials, including paper, fabrics, rubber, plastics, and 3D objects. Flexible optoelectronics, already used in everyday products such as cellphones and fitness trackers, can bend, fold, and flex while remaining functional.

According to the team, this easy and versatile production approach allows anyone to create a personalized light-emitting diode (LED) or photodetector without specialist training or bulky equipment. It builds on earlier work by Wang and Junyi Zhao, who demonstrated how to fabricate stretchable LEDs using a simple inkjet printer.

Chuan Wang said, “Handwriting custom devices was a clear next step after the printer, We had the inks already, so it was a natural transition to take the technology we had already developed and modify it to work in regular ballpoint pens where it could be cheap and accessible to all.”

Their innovative handwriting approach enables anyone to create multicolor LEDs and photodetectors in minutes. The method uses the simplicity of a ballpoint pen with specially designed inks made of conductive polymers, metal nanowires, and crystalline substances known as perovskites to produce a wide range of emission colors.

It is possible to rapidly, conveniently, and affordably manufacture various functional devices, including disposable electronics, innovative packaging, and customized wearables, such as biomedical sensors, by writing layer after layer with these available inks, similar to using colorful pens.

The team had already created printable ink, but it needed to be modified to increase writability and manage wettability before it could be used in conventional ballpoint pens for handwriting on everyday materials.

Junyi Zhao, a doctoral candidate in Wang’s lab, said, “The translation from printer to ballpoint pen might look simple, but it’s a bit trickier than just loading ink. Our ink is specially formulated, so the pens are universal, meaning they’ll work on almost all substrates. Every single layer of the device is designed to be intrinsically elastic to survive deformation. It can be bent, stretched, and twisted without impacting device performance. For example, LEDs drawn on a glove could tolerate deformations from repeated fist grasping and releasing. LEDs drawn on a rubber balloon could survive inflation-deflation cycles repeatedly.”

The researcher’s main concern was ensuring the ink could be applied to porous and fibrous surfaces, such as paper and textiles, without running or blending. To provide functioning, high-performance optoelectronic devices, the layers must remain separate and avoid the aesthetic disappointment of a smudged design.

The development of ink pens that can be used on any substrate, from paper to party balloons, overcomes significant limitations of traditional LED manufacture, such as the need for flat, smooth substrates and expensive clean-room fabrication equipment. It enables next-generation wearable electronics to become part of daily life in new ways.

He predicts future applications for handwritten electronics that are only restricted by the user’s creativity, such as education, science popularization, electronic packaging, clothes, medical sensors, and bandages. Because of its accessibility and flexibility, this approach has the potential to democratize electronic manufacturing, allowing personalized, stretchy electronic gadgets to become a part of everyday life.

He said, “Cheap, customizable LEDs open up opportunities for hands-on education, more vivid textiles like light-up clothing or greeting cards, and smart packaging. One area we’re excited about is medical applications. Handwritten light emitters and detectors allow more patient-specific flexibility in creating wearable biomedical sensors and bandages with photodetectors and infrared LEDs drawn onto them to measure pulse oximetry or speed wound healing.”

The Bill & Melinda Gates Foundation provided funding for this study.

Journal Reference:

- Junyi Zhao,Chuan Wang, et al. Handwriting of perovskite optoelectronic devices on diverse substrates. Nature Photonics. 10.1038/s41566-023-01266-1