The oxygen evolution reaction is essential to make chemicals and energy carriers using electrons. These processes include hydrogen generation as a byproduct of oxygen evolution.

But this reaction requires a catalyst material. Existing versions of catalysts use rare and expensive elements such as iridium, limiting the potential of such fuel production. There has been a big effort in the community to find alternatives.

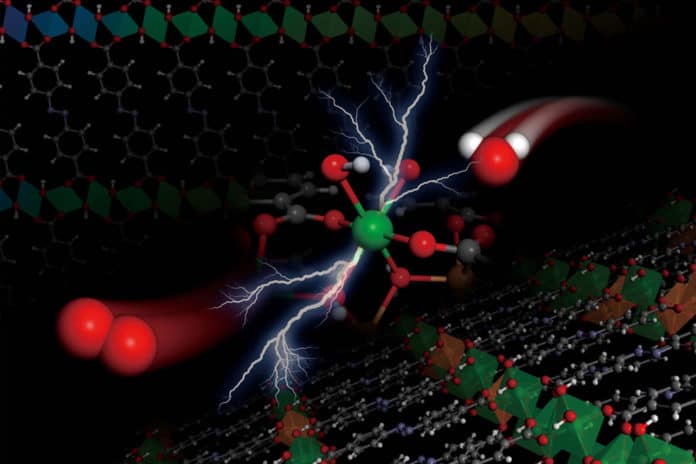

Researchers at MIT and elsewhere have developed an entirely new type of catalyst material. Scientists named their material a metal hydroxide-organic framework (MHOF). The material uses inexpensive and abundant components.

Thanks to the family of materials used in the material, scientists could precisely tune the catalyst’s structure and composition to the needs of a particular chemical process.

Professor Yuriy Román-Leshkov said, “Other teams have explored the use of metal hydroxides, such as nickel-iron hydroxides. But such materials have been difficult to tailor to the requirements of specific applications. Now, though, the reason our work is quite exciting and quite relevant is that we’ve found a way of tailoring the properties by nanostructuring these metal hydroxides uniquely.”

Scientists have drawn inspiration from previous research that has been done on a related class of compounds known as metal-organic frameworks (MOFs). By replacing the metal oxide in such materials with certain metal hydroxides, the team found it possible to create precisely tunable materials that also had the necessary stability to be potentially valuable as catalysts.

Román-Leshkov says, “You put these chains of these organic linkers next to each other, and they direct the formation of metal hydroxide sheets that are interconnected with these organic linkers, which are then stacked and have higher stability. This has multiple benefits, by allowing precise control over the nanostructured patterning, allowing precise control of the electronic properties of the metal, and also providing greater stability, enabling them to stand up to long periods of use.”

When tested, the newly developed catalyst showed surprising performance. It is comparable to the state-of-the-art oxide materials catalyzing for the oxygen evolution reaction.

Professor Yang Shao-Horn said, “This family of materials offers a new space to tune the active sites for catalyzing water splitting to produce hydrogen with reduced energy input.”

MIT graduate student Jiayu Peng said, “The materials can provide “five times greater tunability” than existing nickel-based catalysts, simply by substituting different metals in place of nickel in the compound.”

“This would potentially offer many relevant avenues for future discoveries. The materials can also be produced in extremely thin sheets, which could then be coated onto another material, further reducing the material costs of such systems.”

Shao-Horn says, “So far, the materials have been tested in small-scale laboratory test devices, and the team is now addressing the issues of trying to scale up the process to commercially relevant scales, which could still take a few years. But the idea has great potential to help catalyze the production of clean, emissions-free hydrogen fuel to bring down the cost of hydrogen from this process while not being constrained by the availability of precious metals. This is important because we need hydrogen production technologies that can scale.”

Journal Reference:

- Yuan, S., Peng, J., Cai, B. et al. Tunable metal hydroxide–organic frameworks for catalyzing oxygen evolution. Nat. Mater. (2022). DOI: 10.1038/s41563-022-01199-0