Biomanufacturing of tissues and organs in vitro is our big dream. Over the past few years, 3D bioprinting has been widely applied in the construction of many tissues and organs, such as skins, vessels, hearts, etc. These engineered tissues and organs are used to understand disease formation and progression or to develop biological substitutes to repair or replace damaged organs.

Despite significant advances in this area, currently used in situ bioprinting technologies are not devoid of limitations. Certain devices are only compatible with specific types of bioink, while others can only create small patches of tissue at a time. In addition, their designs are often complex, which makes them expensive and limits their application.

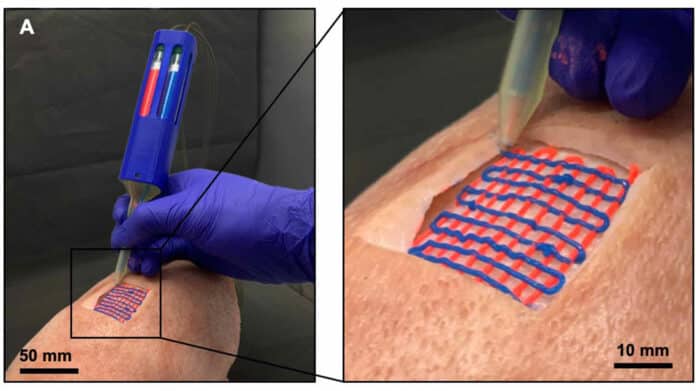

In a breakthrough study, a research team from the University of Victoria in Canada developed a handheld in situ bioprinter with a convenient modular design that allows the printing of complex biocompatible structures.

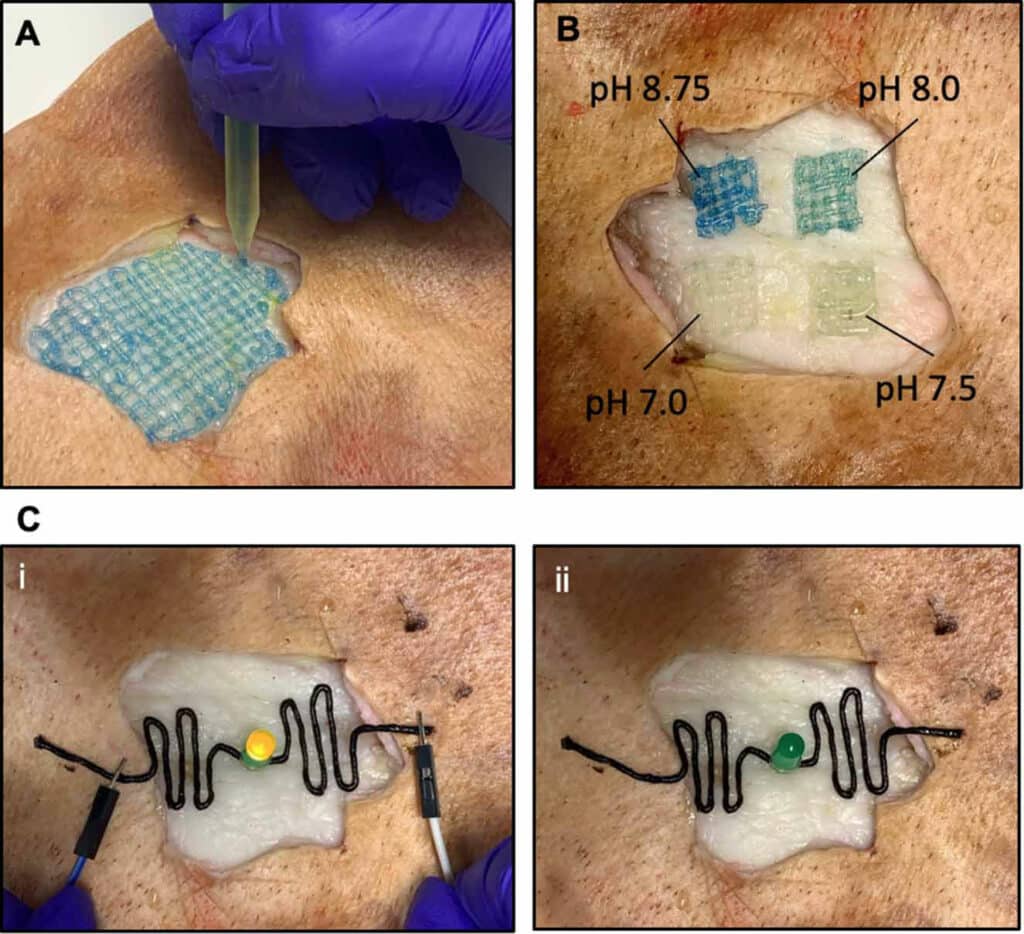

The new bioprinter addresses key limitations of previous designs – the ability to print multiple materials and control the physicochemical properties of printed tissues. The ergonomic design of the handheld bioprinter facilitates the shape-controlled biofabrication of multi-component fibers with different cross-sectional shapes and material compositions.

The handheld device has multiple bioink cartridges, each independently controlled by a pneumatic system. Therefore, the device operator has ample control over the printing mixture, which makes it easy to create structures with the required properties. The device also includes a cooling module and a light-emitting diode photocuring module that provides additional control.

The versatility of this platform to produce biosensors and wearable electronics was demonstrated by incorporating conductive materials and integrating pH-responsive dyes.

The handheld in situ bioprinter will pave the way for a wide variety of applications in regenerative medicine, drug development and testing, and custom orthotics and prosthetics. This portable bioprinter may help physicians match a patient’s tissue anatomy with greater accuracy and convenience, thus enhancing the functionality and aesthetic of the bioprinted construct.

“In situ, bioprinting is suitable for repairing large defects caused by trauma, surgery, or cancer, which requires large-scale tissue constructs. In the long term, this technology can eliminate the need for organ donors while also lowering the risks associated with transplantation, allowing patients to enjoy longer and healthier lives,” says Prof. Mohsen Akbari from the University of Victoria in Canada.

Journal reference:

- Erik Pagan, Evan Stefanek, Amir Seyfoori, Mahmood Razzaghi, Behnad Chehri, Ali Mousavi, Pietro Arnaldi, Zineb Ajji, Daniela Ravizzoni Dartora, Seyed Mohammad Hossein Dabiri, Anne Monique Nuyt, Ali Khademhosseini, Houman Savoji, and Mohsen Akbari. A handheld bioprinter for multi-material printing of complex constructs. Biofabrication, 2023; DOI: 10.1088/1758-5090/acc42c