MIT and Duke University chemists developed a novel approach to strengthening polymers by inserting weaker links into the material.

The researchers discovered that utilizing a weaker form of crosslinker to attach parts of the polymer building blocks could boost the materials’ tearing resistance tenfold.

These rubber-like polymers are extensively utilized in automobile parts and as “ink” for 3D-printed products. The researchers are investigating the possibility of expanding this approach to other materials, such as rubber tires.

Jeremiah Johnson, a professor of chemistry at MIT and one of the senior authors of the study, which appears today in Science, said, “If you could make a rubber tire ten times more resistant to tearing, that could have a dramatic impact on the lifetime of the tire and on the amount of microplastic waste that breaks off.”

“Polymer engineers know how to make materials tougher, but it invariably involves changing some material property you don’t want to change. Here, the toughness enhancement comes without any other significant change in physical properties — at least that we can measure, and it is brought about through the replacement of only a small fraction of the overall material.” says Stephen Craig, a professor of chemistry at Duke University who is also a senior author of the paper.

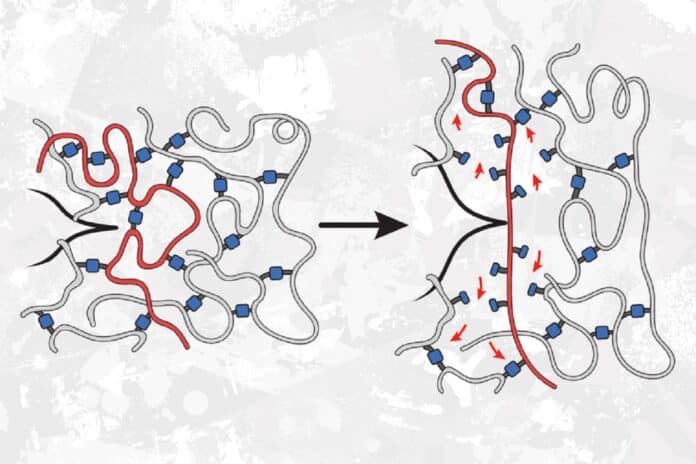

The researchers discovered that using weaker end-linkers to tie the polymer strands together weakened the composite. The weaker linkers, which contain cyclic molecules known as cyclobutane, can be broken with far less force than those typically employed to connect these building blocks.

A new study looked into a different polymer network in which polymer strands crosslinked to other strands at random points rather than being united at the ends. When the researchers employed weaker linkers to connect the acrylate building blocks this time, the material became significantly more resistant to tearing.

This method was used to demonstrate that polyacrylates with some weaker linkers were nine to ten times more difficult to rip than polyacrylates manufactured with stronger crosslinking molecules. Even though the weak crosslinkers made up only around 2 percent of the material’s overall composition, this result was nevertheless obtained. Additionally, the researchers demonstrated that the material’s other features, such as its resistance to degrading under heat, were unaffected by the composition change.

Two materials rarely have the same network-level structure and characteristics but exhibit tearing that varies by magnitude. The researchers are investigating the viability of employing this method to raise the hardness of other materials, such as rubber.

The group’s research on polymer strength is a component of the Centre for the Chemistry of Molecularly Optimised Networks, funded by the National Science Foundation and led by Craig. The center’s goal is to learn how the molecular characteristics of polymer networks affect their physical behavior.

The researchers also demonstrated that the material’s other features, such as its resistance to degrading under heat, were unaffected by this altered composition.

Johnson said, “For two materials to have the same structure and same properties at the network level, but have an almost order of magnitude difference in tearing, is quite rare.”

The researchers are currently exploring the possibility of using this strategy to increase the hardness of other materials, such as rubber.

Craig said, “There’s much to explore here about what enhancement level can be gained in other types of materials and how best to take advantage of it.”

The Centre for the Chemistry of Molecularly Optimised Networks, which receives funding from the National Science Foundation, is where the group’s work on polymer strength is housed. Under Craig’s direction, this Center aims to investigate how the molecular characteristics of polymer networks affect their physical behavior.

Journal Reference:

- Liel Sapir,Danyang Chen, et al. Facile mechanochemical cycloreversion of polymer crosslinkers enhances tear resistance. Science. DOI: 10.1126/science.adg3229