Food printing is one of the emerging applications. 3D food printing allows customizing nutrients based on individual needs, fabricating aesthetically pleasing food, and modifying the food’s internal structures.

Different 3D printing mechanisms have been demonstrated for food printing; selective laser sintering (SLS) applies a laser to melt and fuse powder particles. In SLS, the printable materials are limited to those based on sugars and fats to ensure thermal fusion by laser sintering.

However, these methods are not always compatible with temperature-sensitive nutrients found in certain types of food. It often requires rheology modifiers or additives to stabilize printed structures.

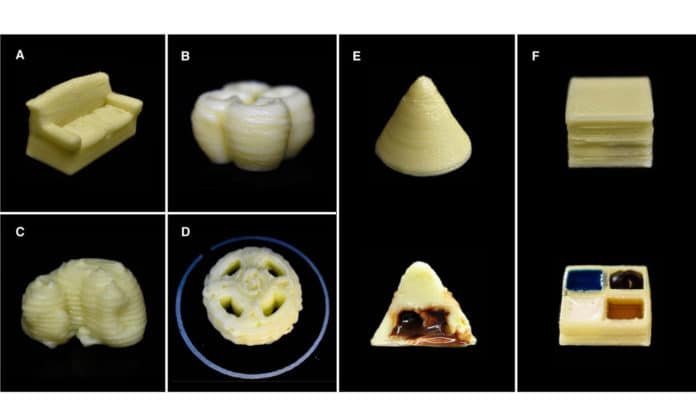

To tackle these limitations, scientists from the Singapore University of Technology and Design (SUTD)’s Soft Fluidics Lab developed a method to perform direct ink writing (DIW) 3-D printing of milk-based products at room temperature while maintaining its temperature-sensitive nutrients.

They changed the printing ink’s rheological properties and demonstrated DIW 3-D printing of milk by cold-extrusion with a single milk product—powdered milk. They found that The team found that milk powder’s concentration allowed for the simple formulation of 3-D-printable milk inks using water to control the rheology.

Lead author and SUTD Ph.D. candidate Mr. Lee Cheng Pau said, “This novel yet simple method can be used in formulating various nutritious foods including those served to patients in hospitals for their special dietary needs.”

Assistant Professor Michinao Hashimoto, the principal investigator of the study, said, “Cold-extrusion does not compromise heat-sensitive nutrients and yet offers vast potential in 3-D printing of esthetically pleasing, nutritionally controlled foods customized for individual requirements.”

Journal Reference:

- Cheng Pau Lee et al., 3D printing of milk-based product, RSC Advances (2020). DOI: 10.1039/D0RA05035K