A simple walk on any beach, anywhere, and the plastic waste spectacle is present. All over the world, the statistics are ever growing, staggeringly. Tons of plastic debris is discarded every year, everywhere, polluting lands, rivers, coasts, beaches, and oceans.

The discovery of keeping plastics out of the landfill and at the same time, meeting the needs of the food industry is full of obstacles. A biodegradable replacement for petroleum-based items needs to fulfill a wide range of guidelines and, up until now, attempts at viable replacements from renewable sources have confronted restricted accomplishment due to preparing and financial limitations. Among the hindrances, items to date have been too brittle for food packaging.

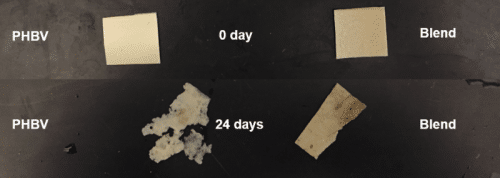

Now, a new study by Ohio State University has discovered a new solution. They found that combining natural rubber with bioplastic in a novel way results in a much stronger replacement for plastic, one that is already capturing the interest of companies looking to shrink their environmental footprints.

According to scientists, a rubber-toughened product derived from microbial fermentation could mimic as conventional plastic. During the experiment, scientists achieved the greatest success in that area so far.

Lead author Xiaoying Zhao, a postdoctoral researcher in Ohio State’s Department of Food Science and Technology said, “Previous attempts at this combination were unsuccessful because the softness of the rubber meant the product lost a lot of strength in the process.”

Scientists melted Previous attempts at this combination were unsuccessful because the softness of the rubber meant the product lost a lot of strength in the process. The resultant product was 75 percent tougher and 100 percent more flexible than PHBV on its own. It means, it can be easily used in food packaging.

Study’s senior author, Yael Vodovotz, a professor of food science and technology at Ohio State said, “Other research teams have combined rubber and PHBV, but the products have been too weak to withstand all the demands of a food package – from processing to shipping, to handling in stores and homes, especially containers that are used for freezing and then microwaving.”

“Increased flexibility, without a significant loss of strength, is particularly important when it comes to plastic films commonly used to package everything from fresh produce to frozen foods.”

Zhao said, “While other attempts at making this type of rubber-enhanced bioplastic have reduced the strength of the PHBV by as much as 80 percent, only 30 percent of the strength was lost in this study – a much more manageable amount.”

Co-author Katrina Cornish, an expert in natural rubber and professor of horticulture and crop science at Ohio State said, “Toughness, which was improved, is different from strength. Imagine trying to pull a block of concrete apart with your hands. That’s testing its strength. But karate chopping it with your hand or foot is testing its toughness – how easily it breaks. You can never pull it apart, but if you’re strong enough you can break it.”

A great part of the scientists’ current focus is on the potential utilization of different biodegradable – and generally naturally concious– materials they may use as fillers to additionally strengthen the mix. They’ve examined utilizing the “cake” deserted after a fellow researcher extricates oil from spent coffee beans. Tomato skins are under thought, as are eggshells.

Vodovotz said, “We want something that would otherwise go to waste that is sustainable and also relatively cheap. They’re even looking at the potential to attack two environmental problems at once, by seeing how invasive grasses that environmentalists are yanking out of waterways might play with the rubber-infused mix. We could dry them, grind them up and potentially use these grasses as a fibrous filler.”

“As the team works to move its technology out of the lab and into the food industry, there will be many details to work out depending on a company’s individual priorities and concerns and that may mean tinkering with the mix.”

The Center for Advanced Processing and Packaging Studies provided funding for the study published in the journal Polymers.