A piece of paper fold over ordinarily ready to convey more weight than a level sheet of paper of a similar length. Thus, folding can likewise upgrade the mechanical properties of graphene.

A worldwide group of analysts, partnered with UNIST has found that folding is an effective system to consolidate vast region monolayer graphene films on polymer composites and that doing as such enhances mechanical fortification.

This achievement has been driven by Distinguished Professor Rodney S. Ruoff and his exploration assemble from the Center for Multidimensional Carbon Materials (CMCM), inside the Institute for Basic Science (IBS) at UNIST. Educator Nicola Pugno from University of Trento in Italy, and Professor Seunghwa Ryu and Dr. Stefano Signetti from KAIST, gave hypothesis and displaying that supplemented the exploratory outcomes from Professor Ruoff’s gathering.

The exploration aggregate announced that they had prevailed with regards to collapsing an A5-sized, 400-nanometer thick polycarbonate film fifty-fifty 12 times. Their discoveries demonstrated this new approach utilizing collapsing gives critical additional solidifying, fortifying and toughening of the final composite piece joining the folded graphene.

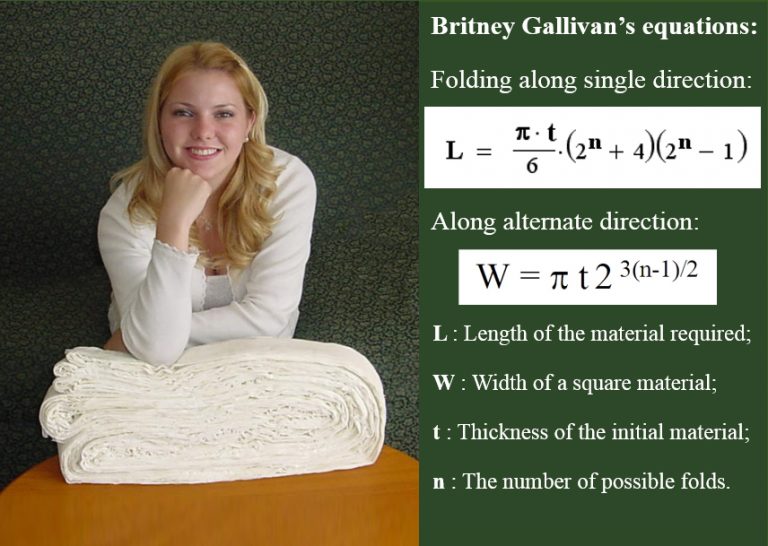

Professor Ruoff said, “This work originated from my interest in folding. When Britney Gallivan was a high school student in California back in 2002, she demonstrated that a single piece of paper, about 1,200 meters in length, could be folded in half twelve times. Before she succeeded that, it has been traditionally thought that the maximum number of times that paper or other materials can be folded in half was 7—including by the best mathematicians of the day.”

Utilizing a water-air interface, scientists primarily folded an A5-sized, 400-nanometer thick polycarbonate film into equal parts 12 times, yielding a millimeter-thick mass material—an intriguing achievement onto itself. He then ‘filled’ large area monolayer graphene film into the collapsed overlay by beginning with an A5-sized 400-nanometer thick polycarbonate film however now covered with a solitary layer of A5-sized graphene that had been developed by compound vapor testimony by Professor Haofei Shi and associates from Chongqing Institute of Green and Intelligent Technology in China.

Distinguished Professor Ruoff said, “When pulled on, graphene is among the stiffest materials and if it can be made free of defects will be one of the strongest materials. Therefore, optimizing its incorporation in composites for reinforcement is an important scientific challenge.”

Dr. Wang also folded this A5-sized bilayer sheet of polycarbonate and graphene 12 times, which means that there were 2^12, thus 4096 layers of graphene present in the final composite structure, that had lateral dimensions of about 3 mm x 2 mm with a thickness of ~3 mm.

Larger length x width (that would likewise be more slender) examples of the last collapsed test were required for mechanical testing. Wang along these lines made a progression of tests each with 10 folds (instead of 12), and utilized a ‘three-point bending test’ toward contemplating their mechanical reaction.

With an astoundingly low volume division of graphene of just 0.085% (under 1 section in 1000), the Young’s modulus (inherent firmness), quality (push that the material breaks at), and durability modulus (vitality devoured in breaking the example) were improved in the collapsed composite by a normal of 73.5%, 73.2%, and 59.1%, respectively.

From the graphene creases alone Young’s modulus was expanded by 24.2%, quality by 25.4%, and strength modulus by 14.5%. Note that these qualities are brought down limits, from the group’s display. Therefore an astounding mechanical support from the consolidated collapsing and stacking of graphene was found.

Professor Pugno said, “The fold plays a special role in stiffening and strengthening the composite. The folded structure can sustain a larger bending force as compared with the analog of stacked but disconnected layers, which could be explained by the improved layer-layer interaction generated from the additional constraint(s) by the folds.”

Professor Ryu and Dr. Stefano Signetti from KAIST who provided the theory used finite element modeling (FEM) to simulate the bending of the folded laminates and discovered that the folded configuration provides much higher bending stiffness with respect to the stacked configuration with the equivalent 1024 layers of embedded graphene.

Dr. Signetti, a postdoctoral fellow from KAIST said, “The additional constraint given by the folds results in both higher specific deformation energy stored in the composite plate, and also higher bending force at the same imposed displacement as compared with the plate with the same number of stacked layers but without the folds.”

Distinguished Professor Ruoff said, “The models presented in this work could be helpful for the design of other kinds of two-dimensional materials embedded in multilayered three-dimensional composites, which can be realized at large size. Besides the mechanical reinforcement, there are other potential applications of the folded laminates.”

Dr. Wang further noted that “By combining various two-dimensional nanomaterials that contribute special functionality, folding can be used to obtain macro-scale materials for many other potential applications, including but not limited to energy storage and conversion, and thermal management.”

This research was supported by the Institute for Basic Science and has been published online in the journal Advanced Materials on July 11, 2018.