Blood transfusions spare many lives every year, however over a large portion of the world’s countries don’t have adequate blood supply to address their needs. The capacity to manufacture RBCs on demand, particularly the universal donor blood (O+), would fundamentally profit those needing transfusing conditions like leukemia by circumventing the requirement for large volume blood draws and difficult cell isolation processes.

Easier and faster manufacturing of RBCs would also significantly impact blood banks worldwide and reduce dependence on donor blood, which has a higher risk of infection.

However, manufacturing RBCs is time-consuming and creates undesirable by-products, with current purification methods being costly and not optimal for large-scale therapeutic applications.

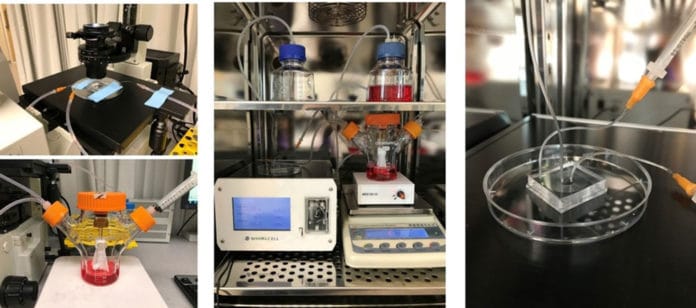

Scientists from Singapore-MIT Alliance for Research and Technology (SMART), MIT’s research enterprise in Singapore, have demonstrated a new way to manufacture human red blood cells (RBCs) that cuts the culture time by half compared to existing methods. They have designed an optimized intermediary cryogenic storage protocol that reduces the cell culture time to 11 days post-thaw, eliminating the need for continuous 23-day blood manufacturing. This is aided by the team’s complementary technologies for highly efficient, low-cost RBC purification and more targeted sorting.

Kerwin Kwek, lead author of the paper and senior postdoc at SMART CAMP, said, “Traditional methods for producing human RBCs usually require 23 days for the cells to grow, expand exponentially, and finally mature into RBCs. Our optimized protocol stores the cultured cells in liquid nitrogen on what would normally be Day 12 in the typical process, and upon demand thaws the cells and produces the RBCs within 11 days.”

Scientists also developed novel purification and sorting methods by changing existing Dean flow fractionation (DFF) and deterministic lateral displacement (DLD) and building up a trapezoidal cross-section design and microfluidic chip for DFF sorting and a unique sorting system accomplished with an inverse L-shape pillar structure for DLD sorting.

These new sorting and purification techniques leverage the RBC’s size and deformability for purification instead of spherical size. As most human cells are deformable, this technique can have wide biological and clinical applications, such as cancer cell and immune cell sorting and diagnostics.

During tests, the purified RBCs were found to hold their cellular functionality, as exhibited by high malaria fever parasite infectivity. This affirms that the new RBC sorting and purifying technologies are ideal for exploring malaria pathology.

Kwek said, “Our novel sorting and purification methods result in significantly faster cell processing time and can be easily integrated into current cell manufacturing processes. The process also does not require a trained technician to perform sample handling procedures and is scalable for industrial production.”

Journal Reference:

- Kerwin Kwek Zeming et al. Microfluidic label-free bioprocessing of human reticulocytes from erythroid culture. DOI: 10.1039/C9LC01128E