Owing to the unique combination of electrical conductivity and tissue-like mechanical properties, conducting polymer hydrogels have emerged as a promising candidate for bioelectronic interfacing with biological systems. However, despite the recent advances, the development of hydrogels with both excellent electrical and mechanical properties in physiological environments is still challenging.

Engineers at MIT have created a Jell-O-like substance that is metal-free, as flexible and durable as biological tissue, and that conducts electricity similarly to traditional metals. The material can be converted into printable ink, which the scientists patterned into flexible, rubbery electrodes. The brand-new material, high-performance conducting polymer hydrogel, can potentially replace metals as functional gel-based electrodes.

This material functions similarly to metal electrodes but comprises gels similar to those found in our bodies and have similar water content. According to scientists, this Jell-O-like electrode can replace metal to stimulate nerves and interface with the heart, brain, and other organs in the body.

In their latest investigation, Yuk and his colleagues discovered that conductive polymers and hydrogels must be combined in a different method to improve the electrical and mechanical properties of the individual components.

People used uniform, random mixing of the two materials in the past. These combinations resulted in gels with polymer particles distributed at random. The team understood that both materials needed to be blended to oppose one another, known as phase separation, to sustain the electrical and mechanical properties of the conductive polymer and the hydrogel, respectively. Each component might join its specific polymers to create lengthy, tiny strands while mixing in this slightly separated state.

Xuanhe Zhao, professor of mechanical engineering and civil and environmental engineering at MIT, said, “Imagine we are making electrical and mechanical spaghetti. The electrical spaghetti is the conductive polymer, which can now transmit electricity across the material because it is continuous. And the mechanical spaghetti is the hydrogel, which can transmit mechanical forces and be tough and stretchy because it is also continuous.”

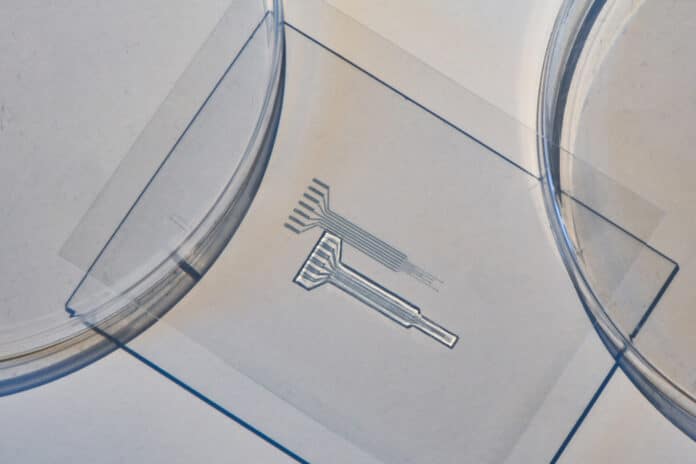

The researchers then modified the technique to turn the spaghettified gel into ink, which they then printed onto pure hydrogel films in the shape of traditional metal electrodes using a 3D printer.

MIT postdoc Tao Zhou, now an assistant professor at Penn State University, said, “Because this gel is 3D-printable, we can customize geometries and shapes, which makes it easy to fabricate electrical interfaces for all kinds of organs.”

The researchers then placed the printed, Jell-O-like electrodes onto the rat spinal cord, sciatic nerve, and heart. The electrodes remained stable throughout, with little inflammation or damage to the surrounding tissues, according to the team’s tests of their electrical and mechanical performance in the animals for up to two months. The electrodes could also transmit electrical pulses from the heart to a monitor outside the body. They could also provide brief electrical pulses to the sciatic nerve and spinal cord, which in turn triggered motor activity in the limbs and muscles that were connected to them.

Hyunwoo Yuk SM ’16, Ph.D. ’21, co-founder of SanaHeal, a medical device startup, said, “These patients need a few weeks of electrical support to avoid heart attack as a side effect of surgery. So, doctors stitch a metallic electrode on the surface of the heart and stimulate it over weeks. We may replace those metal electrodes with our gel to minimize complications and side effects that people currently accept.”

Journal Reference:

- Zhou, T., Yuk, H., Hu, F. et al. 3D printable high-performance conducting polymer hydrogel for all-hydrogel bioelectronic interfaces. Nature Materials. (2023). DOI: 10.1038/s41563-023-01569-2