According to a new study by the University of California, Riverside– Adaptive fast-charging methodology for commercial electric batteries can cause them to crack, leak, and lose their storage capacity. To address this issue, scientists, hence come up with a method or charging at lower temperatures with less risk of catastrophic damage and loss of storage capacity.

Scientists charged one set of discharged Panasonic NCR 18650B cylindrical lithium-ion batteries, found in Tesla cars, using the same industry fast-charging method as fast chargers found along freeways. They also charged a set using a new fast-charging algorithm based on the battery’s internal resistance, which meddles with the progression of electrons. The interior obstruction of a battery fluctuates as per temperature, charge state, battery age, and other factors. High internal resistance can cause problems during charging.

This newly developed charging method is an adaptive system that gains learn from the battery by checking the battery’s internal resistance during charging. It rests when internal resistance kicks in to wipe out the loss of charge limit.

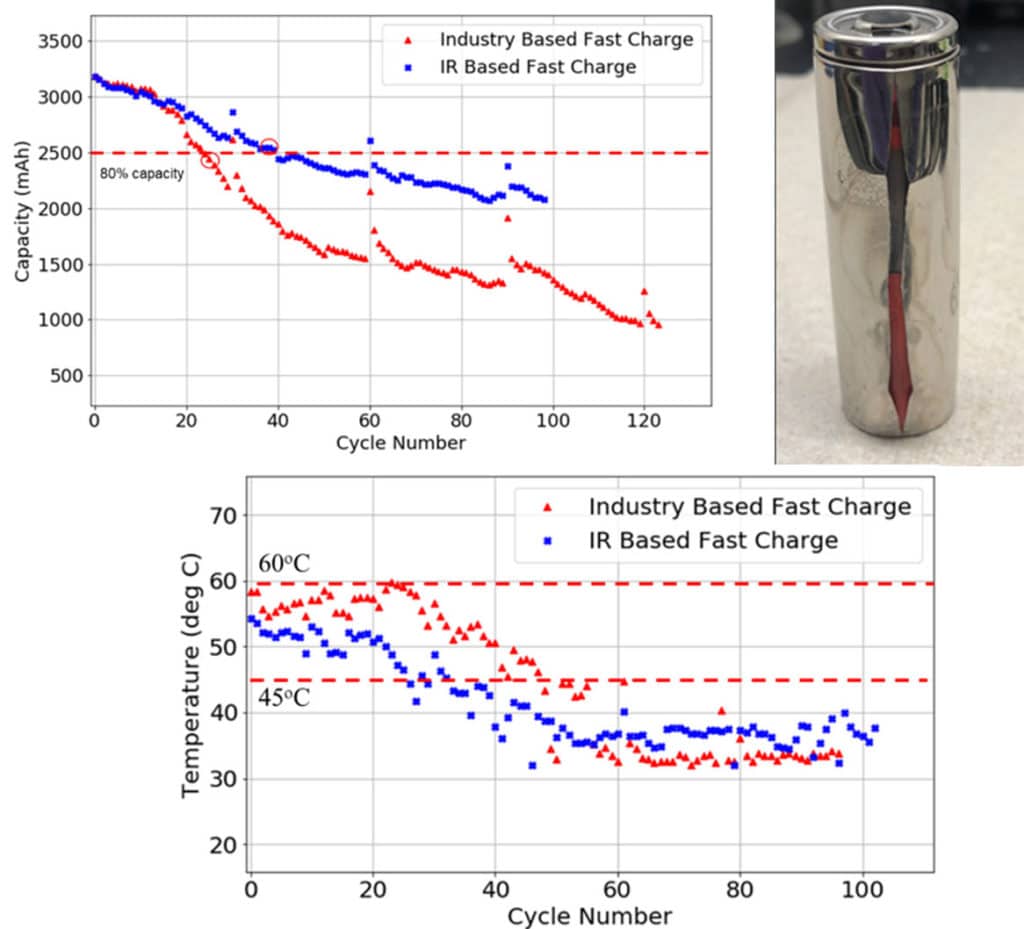

For the first 13 charging cycles, the battery storage capacities for both charging techniques remained similar. After that, however, the industry fast-charging technique caused the capacity to fade much faster— after 40 charging cycles, the batteries kept only 60% of their storage capacity. Batteries charged using the internal resistance charging method retained more than 80% capacity after the 40th cycle.

At 80% capacity, rechargeable lithium-ion batteries have reached the end of their useful life for most purposes. Batteries charged using the industry fast-charging method reached this point after 25 charging cycles, while internal resistance method batteries were good for 36 cycles.

Doctoral student and co-author Tanner Zerrin said, “Industrial fast-charging affects the lifespan of lithium-ion batteries adversely because of the increase in the internal resistance of the batteries, which in turn results in heat generation.”

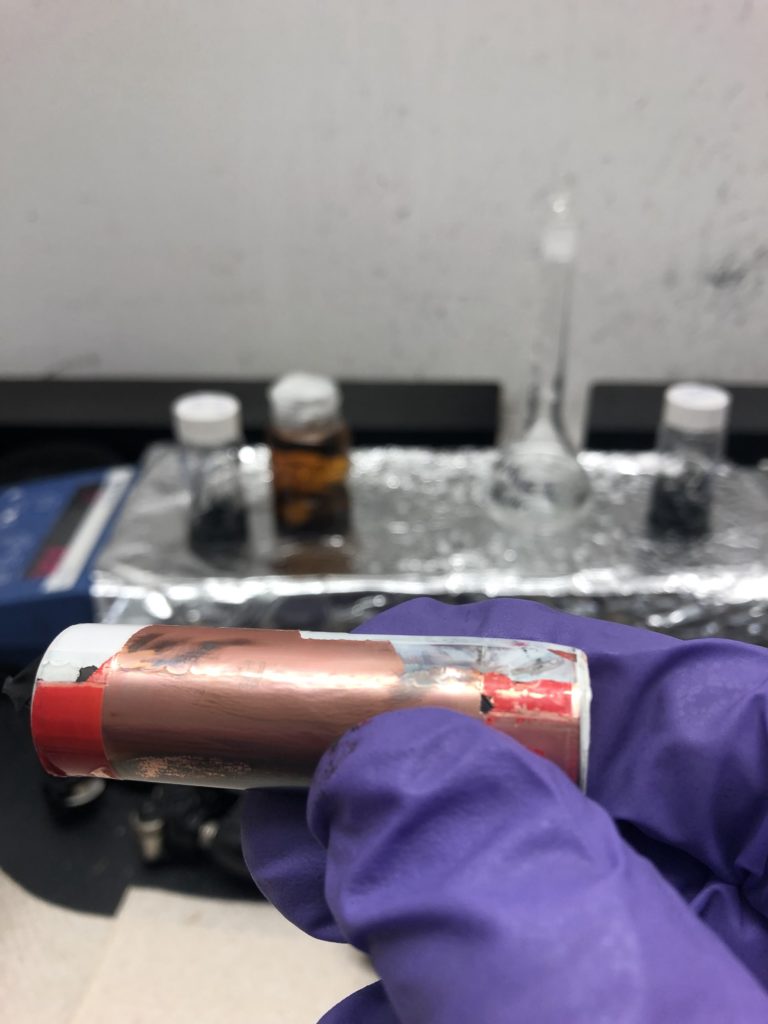

“Worse, after 60 charging cycles, the industry method battery cases cracked, exposing the electrodes and electrolyte to air and increasing the risk of fire or explosion. High temperatures of 60 degrees Celsius/140 degrees Fahrenheit accelerated both the damage and risk.”

Mihri Ozkan, a professor of electrical and computer engineering, said, “Capacity loss, internal chemical and mechanical damage, and the high heat for each battery are major safety concerns, especially considering there are 7,104 lithium-ion batteries in a Tesla Model S and 4,416 in a Tesla Model 3.”

Cengiz Ozkan, a professor of mechanical engineering in the Marlan and Rosemary Bourns College of Engineering, said, “Internal resistance charging resulted in much lower temperatures and no damage. Our alternative adaptive fast charging algorithm reduced capacity fade and eliminated fractures and changes in composition in the commercial battery cells.”

Bo Dong, a doctoral student, and paper co-author said, “The proposed adaptive fast charging provides a novel perspective for the design of fast charging technology for electric vehicles with better safety performance and longer battery lifespan.”

Scientists have applied for a patent on the adaptive internal resistance fast-charging algorithm that could be licensed by the battery and car manufacturers. In the meantime, the UCR Battery Team recommends minimizing the use of commercial fast chargers, recharging before the battery is completely drained, and preventing overcharging.

The study is published in the journal Energy Storage.