Using muscle fibers, scientists have been trying to design materials similar to muscles for various applications, such as in soft robotics. What if scientists could directly make synthetic muscles using microbes?

Scientists at the McKelvey School of Engineering at Washington University in St. Louis have developed a synthetic chemistry approach to polymerize proteins inside have developed a synthetic chemistry approach to polymerize proteins inside engineered microbes. This allowed the microbes to create the high molecular weight muscle protein, titin, and then spin it into fibers.

Scientists were able to produce a synthetic muscle protein called titin. Titin is one of the three major protein components of muscle tissue. Critical to its mechanical properties is the large molecular size of titin.

Scientists created bacteria to compile smaller protein segments into ultra-high molecular weight polymers around two megadaltons in size. They did this to avoid issues that typically prevent bacteria from producing large proteins.

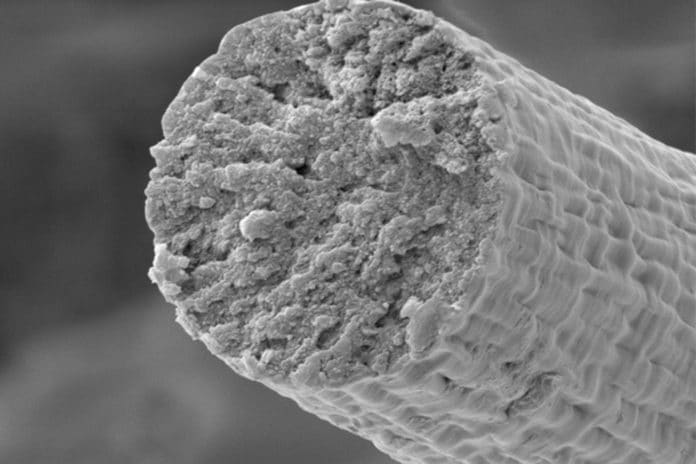

Then, by using a wet-spinning process, they converted the proteins into fibers with 10 microns in diameter. The team then analyzed the structure of these fibers. They wanted to identify the molecular mechanisms that enable their unique combination of exceptional toughness, strength, and damping capacity or the ability to dissipate mechanical energy as heat.

A Ph.D. student in the Division of Biological and Biomedical Sciences, Cameron Sargent, said, “Aside from fancy clothes or protective armor (again, the fibers are tougher than Kevlar, the material used in bulletproof vests). This material has many potential biomedical applications as well. This synthetic material is presumably biocompatible because it’s nearly identical to the proteins found in muscle tissue. It could therefore be a great material for sutures, tissue engineering, and so on.”

“The beauty of the system is that it’s a platform that can be applied anywhere. We can take proteins from different natural contexts, then put them into this platform for polymerization and create larger, longer proteins for various material applications with greater sustainability.”

Journal Reference:

- Bowen, C.H., Sargent, C.J., Wang, A. et al. Microbial production of megadalton titin yields fibers with advantageous mechanical properties. Nature Communications 12, 5182 (2021). DOI: 10.1038/s41467-021-25360-6