Renewable drop-in fuels produced from CO2 and water using solar energy are a promising solution for making aviation more sustainable. One of the most promising methods for this is the thermochemical process that involves a ceria-based redox cycle, which utilizes the entire solar spectrum as the source of high-temperature process heat to directly produce a syngas mixture suitable for synthesizing kerosene.

However, its solar-to-fuel energy efficiency is hindered by the inadequate isotropic topology of the ceria porous structure. This topology prevents the effective absorption of the incident concentrated solar radiation across its entire volume.

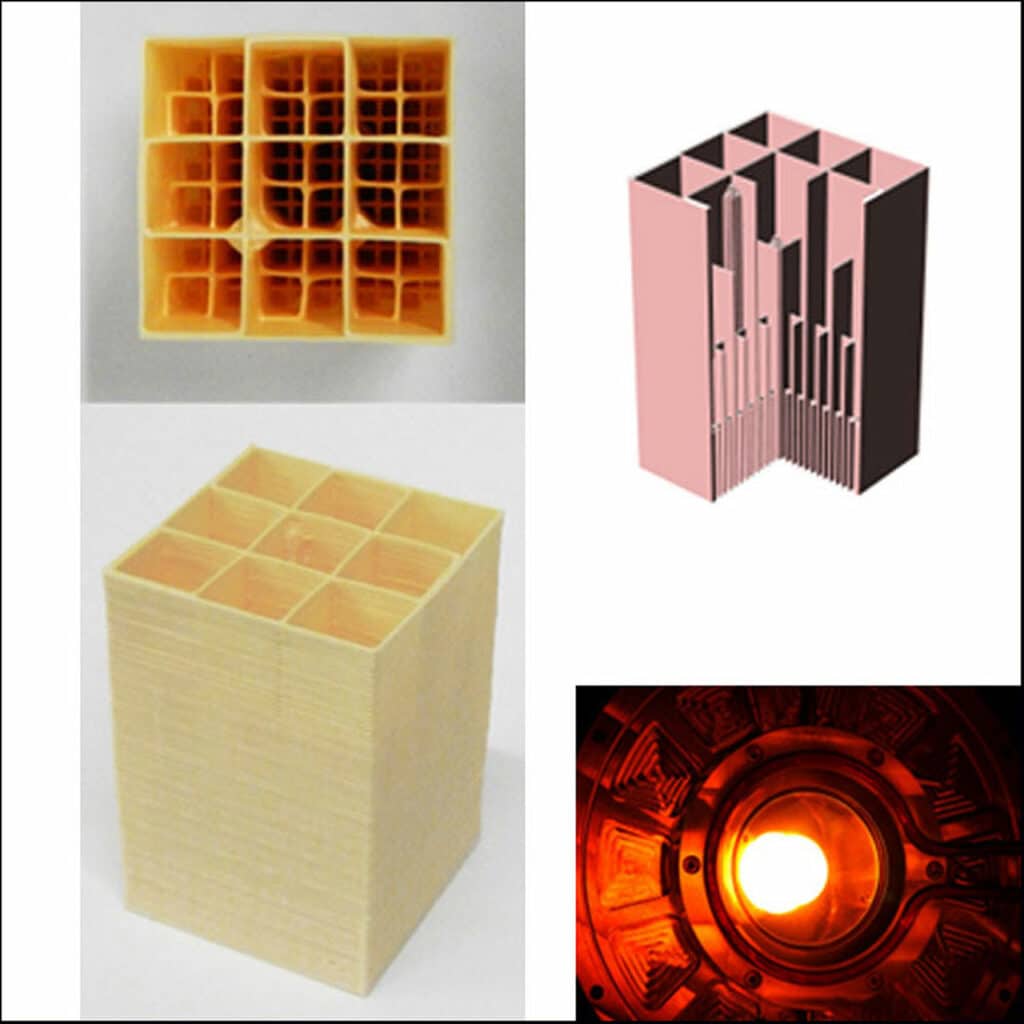

Now, engineers at ETH Zurich have developed a new 3D printing technique to manufacture porous ceramic structures with complex pore geometries to transport solar radiation more efficiently into the reactor’s interior.

The Swiss engineers have been working on the technology to produce liquid fuels from sunlight and air for almost a decade. For this, they have developed a patented solar reactor that is exposed to concentrated sunlight delivered by a parabolic mirror and reaches temperatures of up to 1500 degrees Celsius. The reactor contains a porous ceramic structure made of cerium oxide, where a thermochemical cycle takes place for splitting water and CO2 captured previously from the air.

The outcome is syngas, a mixture of hydrogen and carbon monoxide that can be further processed to produce carbon-neutral liquid fuels, for example, solar kerosene for aviation.

So far, structures with isotropic porosity have been used, but the downside is that they exponentially attenuate the incident solar radiation as it travels into the reactor. As a result, the inner temperatures are lower, which limits the yield of fuel in the solar reactor.

According to researchers, the new graded designs enable transporting solar radiation more efficiently into the reactor’s interior than the previous isotropic designs. The fuel production is enhanced by using ceramic structures with a hierarchically ordered design with channels and pores that are open at the surface and exposed to sunlight. They become narrower towards the rear of the reactor and have proven to be particularly efficient.

This design enables the absorption of the incident concentrated solar radiation over the entire volume and reaches the reaction temperature of 1500°C, boosting the fuel generation.

Initial experimental testing shows that these new 3D-printed reactor structures can produce twice as much solar fuel as the uniform structures when subjected to the same concentrated solar radiation of intensity equivalent to 1000 suns.

“This technology has the potential to boost the solar reactor’s energy efficiency and thus to significantly improve the economic viability of sustainable aviation fuels,” said Aldo Steinfeld, ETH Professor of Renewable Energy Carriers, in an official release.

Through spinouts Climeworks and Synhelion, the ETH Zurich team is further developing and commercializing the technologies.

Journal reference:

- Sebastian Sas Brunser, Fabio L. Bargardi, Rafael Libanori, Noëmi Kaufmann, Hugo Braun, Aldo Steinfeld, André R. Studart. Solar-driven redox splitting of CO2 using 3D-printed hierarchically channelled ceria structures. Advanced Materials Interfaces, 2300452, 2023. DOI: 10.1002/admi.202300452