3D printing is advancing rapidly with a broader range of materials. Initially limited to fast-curing plastics, the technology now accommodates slow-curing plastics, offering benefits like improved elasticity, durability, and robustness. This progress is thanks to a new technology developed by researchers at ETH Zurich and a US start-up that enables these enhanced polymers.

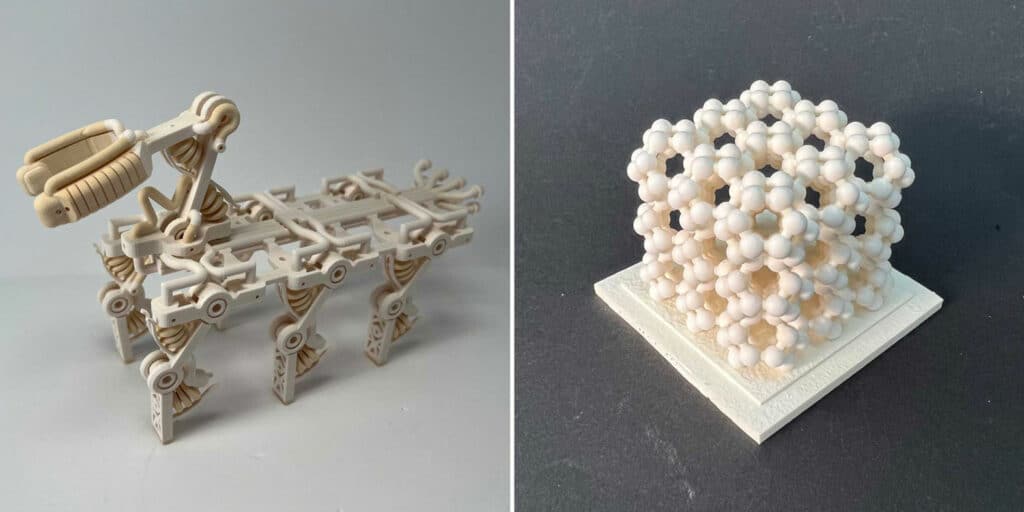

Because of this, scientists can now 3D print intricate, more resilient robots in one go using a range of premium materials. The best part is that scientists have successfully printed a robotic hand with bones, ligaments, and tendons made of different polymers.

The new technology- a laser scanning technique- allows scientists to 3D print complex, more durable robots from various high-quality materials in one go. It also makes combining soft, elastic, and rigid materials easy.

Thomas Buchner, a doctoral student in the group of ETH Zurich robotics professor Robert Katzschmann and the first author of the study, said, “We wouldn’t have been able to make this hand with the fast-curing polyacrylates we’ve been using in 3D printing, so far. We’re now using slow-curing thiolene polymers. These have very good elastic properties and return to their original state much faster after bending than polyacrylates.”

“This makes thiolene polymers ideal for producing the elastic ligaments of the robotic hand.”

ETH Zurich robotics professor Robert Katzschmann, the study’s first author, said, “In addition, the stiffness of thiolenes can be fine-tuned very well to meet the requirements of soft robots. “Robots made of soft materials, such as the hand we developed, have advantages over conventional robots made of metal. Because they’re soft, there is less risk of injury when they work with humans, and they are better suited to handling fragile goods.”

The scientists have improved 3D printing by including a 3D laser scanner that instantly inspects each printed layer for any surface imperfections to accommodate the usage of slow-curing polymers. When printing the subsequent layer, a feedback mechanism corrects for these irregularities by precisely and instantly determining any necessary adjustments to the amount of material to be printed.

Instead of smoothing out uneven layers, the new technology considers the unevenness when printing the next layer.

Using the technology, scientists will plan to explore further possibilities, design even more sophisticated structures, and develop additional applications.

Journal Reference:

- Buchner TJK, Rogler S, Weirich S, Armati Y, Cangan BG, Ramos J, Twiddy S, Marini D, Weber A, Chen D, Ellson G, Jacob J, Zengerle W, Katalichenko D, Keny C, Matusik W, Katzschmann RK: Vision-Controlled Jetting for Composite Systems and Robots, Nature, 15. November 2023, DOI: 10.1038/s41586-023-06684-3