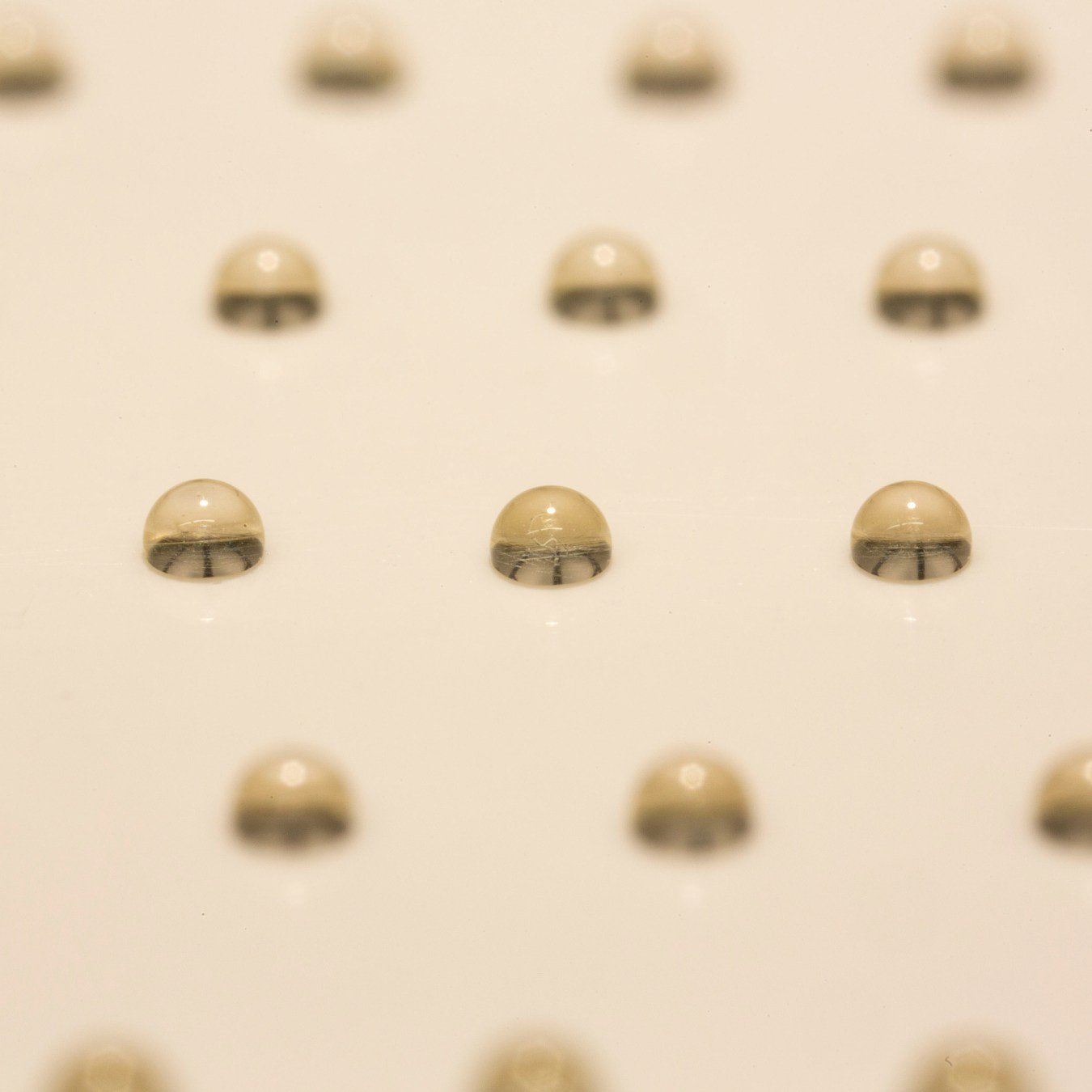

Harvard scientists for the first time have come up with an innovation that uses sound waves to generate droplets from liquids. Using this technique, scientists could manufacture many new biopharmaceuticals, cosmetics, and food.

Jennifer Lewis, senior author of the paper said, “By harnessing acoustic forces, we have created a new technology that enables myriad materials to be printed in a drop-on-demand manner.”

Liquid droplets are used in printing ink on paper to creating microcapsules for drug delivery. However numerous liquids important to scientists are far more thick. For instance, biopolymer and cell-laden solutions, which are crucial for biopharmaceuticals and bioprinting, are no less than 100 times more viscous than water. Some sugar-based biopolymers could be as thick as honey, which is 25,000 times more viscous than water.

Moreover, the viscosity of liquids changes dramatically with temperature and composition. Due to this, the liquids make it more difficult to optimize printing parameters to control droplet sizes.

Daniele Foresti, first author of the paper said, “Our goal was to take viscosity out of the picture by developing a printing system that is independent of the material properties of the fluid.”

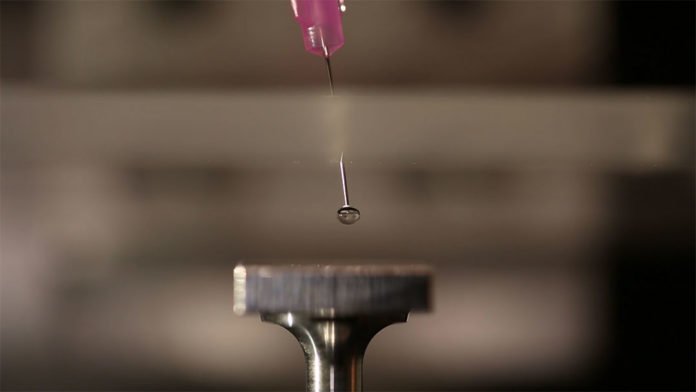

To do so, scientists moved towards acoustic waves. To enhance drop formation, the research team relies on generating sound waves. These pressure waves typically have been used to defy gravity, as in the case of acoustic levitation. Now, the researchers are using them to assist gravity, dubbing the new technique acoustophoretic printing.

The scientists built a subwavelength acoustic resonator that can create a profoundly confined acoustic field bringing about a pulling power surpassing 100 times the normal gravitation forces (1 G) at the tip of the printer nozzle — that is in excess of four times the gravitational force on the surface of the sun.

This controllable power pulls every bead off of the spout when it achieves a particular size and launches it toward the printing target. The higher the plentifulness of the sound waves, the littler the bead estimate, independent of the consistency of the liquid.

Scientists tested the process on an extensive variety of materials, from nectar to stem cell inks, biopolymers, optical resins, and even fluid metals. Imperatively, stable waves don’t go through the droplet, making the strategy safe to utilize even with a delicate organic load, for example, living cells or proteins.

Dan Finotello, director of the National Science Foundation’s Materials Research Science and Engineering Centers (MRSEC) said, “This is an exquisite and impactful example of the breadth and reach of collaborative research. The authors have developed a new printing platform using acoustic forces, which, unlike in other methods, are material-independent and thus offer tremendous printing versatility. The application space is limitless.”

The research is published in Science Advances.