As we strive towards a low-carbon economy and work to minimize global warming, the widespread adoption of electric vehicles (EVs) has been recognized as an essential step on the global roadmap. However, there are still significant concerns surrounding the fast charge capability, driving range, and safety of the automotive lithium-ion batteries (LiBs) that power these vehicles.

One concern with lithium-ion batteries is the potential for lithium plating that occurs during fast charging. It is one of the most detrimental degradation mechanisms that prevent EVs from charging at a rate that is competitive with refueling a combustion engine vehicle.

Now, researchers from Queen Mary University of London, in collaboration with an international team of researchers from the UK and USA, have found a way to prevent lithium plating in electric vehicle batteries, potentially leading to faster charging times and improved performance.

Lithium plating occurs when lithium ions build up on the surface of the battery’s negative electrode, creating a layer of metallic lithium that continues growing. This can damage the battery, shorten its lifespan, and even lead to hazardous events like short circuits and fires.

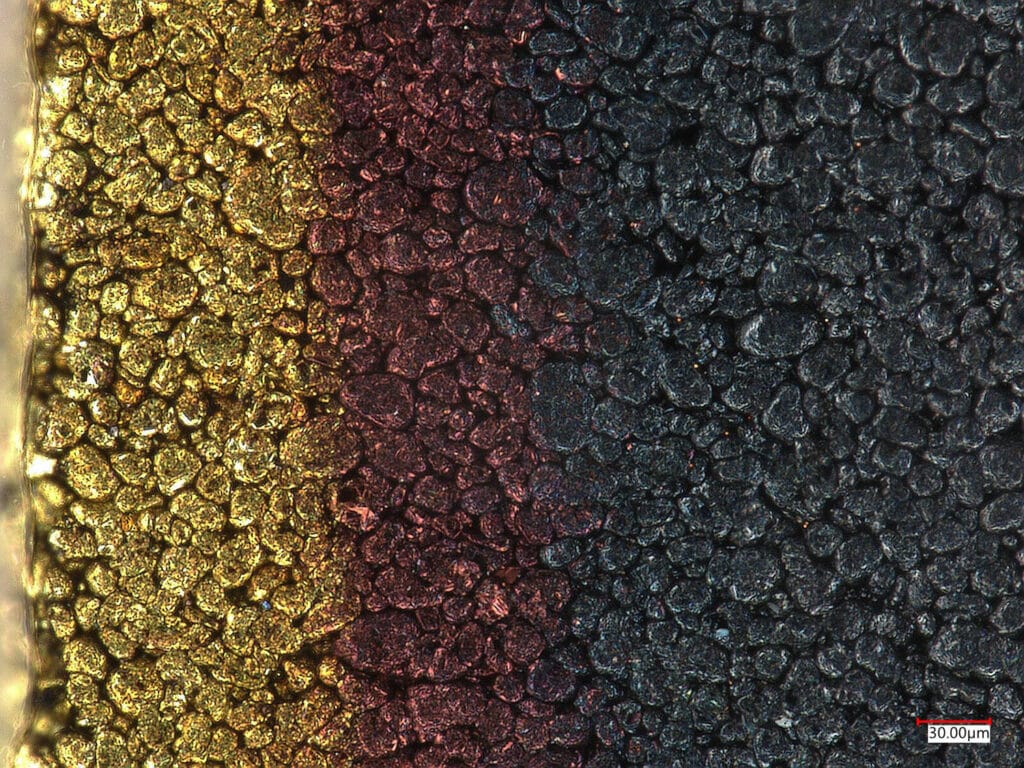

Researchers say optimizing the microstructure of the graphite negative electrode can play a crucial role in mitigating lithium plating. The graphite negative electrode is composed of randomly distributed tiny particles that need precise manipulation to achieve a homogeneous reaction activity and reduce local lithium saturation. This is a key to suppress lithium plating and improve the battery’s performance.

“Our research has revealed that the lithiation mechanisms of graphite particles vary under distinct conditions, depending on their surface morphology, size, shape, and orientation. It largely affects the lithium distribution and the propensity of lithium plating,” said Dr. Xuekun Lu from Queen Mary University of London, who led the research. “Assisted by a pioneering 3D battery model, we can capture when and where lithium plating initiates and how fast it grows. This is a significant breakthrough that could have a major impact on the future of electric vehicles.”

The study provides new insights into developing advanced fast-charging protocols. The study highlights the importance of improving the understanding of the physical processes of lithium redistribution within the graphite particles during fast charging. This knowledge could lead to a more efficient charging process while minimizing the risk of lithium plating.

In addition to accelerating charging durations, the study also reveals that refining the microstructure of the graphite electrode can boost the battery’s energy density. This means that electric cars could travel further on a single charge.

These findings are a major breakthrough in the development of electric vehicle batteries. With faster charging times and longer-lasting batteries, electric cars could become a more practical option for everyday use. Additionally, the improved safety features are definitely a plus. Overall, these findings are a major step forward in achieving a sustainable future for transportation.

Journal reference:

- Xuekun Lu, Marco Lagnoni, Antonio Bertei, Supratim Das, Rhodri E. Owen, Qi Li, Kieran O’Regan, Aaron Wade, Donal P. Finegan, Emma Kendrick, Martin Z. Bazant, Dan J. L. Brett, and Paul R. Shearing. Multiscale dynamics of charging and plating in graphite electrodes coupling operando microscopy and phase-field modelling. Nature Communications, 2023; DOI: 10.1038/s41467-023-40574-6