Designing various 3D structures for mechanical performance is currently of great interest. But in reality, 3D printing is still limited in the properties and materials available for use, especially when printing at very small scales.

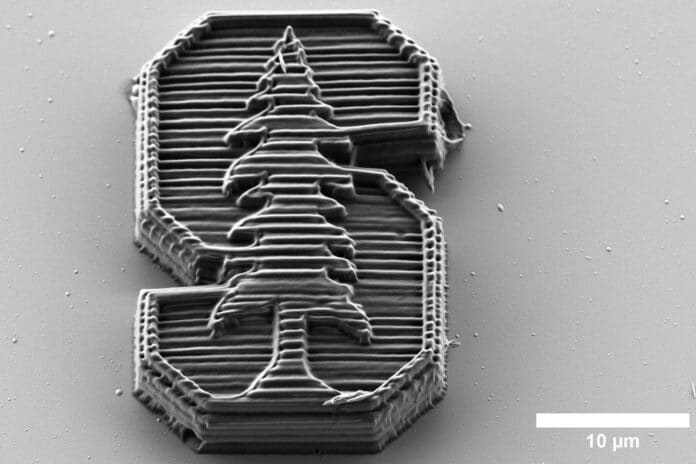

Scientists at Stanford have developed a new material for printing at the nanoscale. They also used the newly created material for printing minuscule lattices that are both strong and light.

In contrast to materials with comparable density, this nanoscale 3D printing material can absorb twice as much energy. Moreover, it is good at resisting forces, so it’s not just the 3D structure but also the material that provides very good protection. In the future, it is expected to be used to create better lightweight protection for fragile pieces of satellites, drones, and microelectronics.

To design this new material, scientists used metal nanoclusters – tiny clumps of atoms – in their printing medium, known as two-photon lithography. The printing material is hardened in this medium through a chemical reaction initiated by laser light. These nanoclusters demonstrated to be good at triggering this reaction. It hence leads to the formation of a material that is a composite of the polymer printing medium and metal.

Wendy Gu, an assistant professor of mechanical engineering and a corresponding author on the paper, said, “The nanoclusters have excellent properties for taking in the laser light and then converting that to a chemical reaction. And they’re able to do this with several classes of polymers, so they’re even more versatile than I expected.”

Scientists combined proteins, acrylates, and epoxies—a few popular polymers in 3D printing—with metal nanoclusters. The nanoclusters also assisted in accelerating the printing process. For instance, scientists could print at a speed of 100 millimeters per second using the nanoclusters and proteins, roughly 100 times quicker than what had previously been possible with nanoscale protein printing.

The ability to carry a big weight in some and the capacity to withstand an impact in others were prioritized when the scientists tested their novel material with various lattice configurations. All the constructions with the nanocluster-polymer composite showed a fantastic mix of energy absorption, strength, and recoverability — or, to put it another way, the capacity to squish and spring back.

Gu said, “The lattice structure certainly matters, but we’re showing here that if the material it’s made out of is optimized, that’s more important for performance. You don’t have to worry about exactly what the 3D structure is if you have the right materials to print with.”

Journal Reference:

- Qi Li et al. Mechanical nanolattices printed using nanocluster-based photoresists. Science. DOI: 10.1126/science.abo6997