Using composite metal foam (CMF), scientists at the North Carolina State University have developed a bulletproof material that can stop the ball and armor-piercing .50 caliber rounds as well as conventional steel armor, even though it weighs less than half as much.

The study, in other words, suggests that it is now possible to make a vehicle completely impervious without compromising safety.

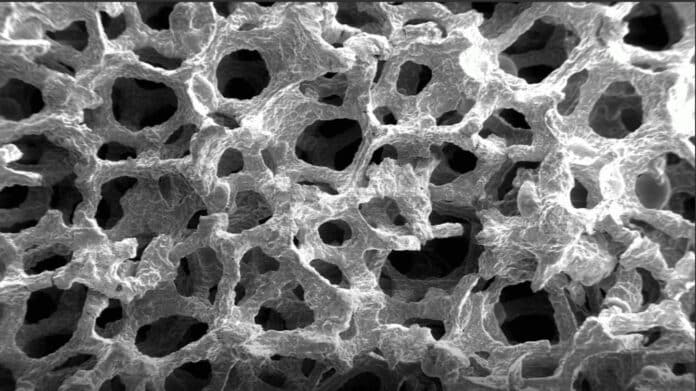

A composite metal foam is a cellular structure consisting of a solid metal (frequently aluminum) with gas-filled pores comprising a large volume. The pores can be sealed (closed-cell foam) or interconnected (open-cell foam). The defining characteristic of metal foams is a high porosity: typically, only 5–25% of the volume is the base metal. The strength of the material is due to the square-cube law.

In this study, the scientists used steel-steel CMF, meaning that both the spheres and the matrix were made of steel.

For the study, scientists fabricated hard armor using a sandwich panel construction consisting of a ceramic faceplate, a CMF core, and a thin aluminum back plate.

They then tested their hard armor system against 0.50 caliber ball and armor-piercing (AP) rounds. The CMF armors were tested with various areal densities at impact velocities between 500-885 m/s. The CMF layer of the armor was able to absorb 72-75% of the kinetic energy of the ball rounds and 68-78% of the kinetic energy of the armor-piercing rounds.

Afsaneh Rabiei, the corresponding author of a paper on the work and a professor of mechanical and aerospace engineering at North Carolina State University, said, “The CMF armor was less than half the weight of the rolled homogeneous steel armor needed to achieve the same level of protection. In other words, we achieved significant weight savings – which benefits vehicle performance and fuel efficiency – without sacrificing protection.”

“This work shows that CMF can offer a significant advantage for vehicle armor, but there is still room for improvement. These findings stem from testing armors we made by combining steel-steel CMF with off-the-shelf ceramic faceplates, aluminum back plates, and adhesive material.”

“We only optimized our CMF material and replaced the steel plate in standard vehicle armor with steel-steel CMF armor. There is additional work we could do to make it even better. For example, we would like to optimize the adhesion and thickness of the ceramic, CMF, and aluminum layers, which may lead to even lower total weight and improved efficiency of the final armor.”

The study is published in the journal Composite Structures.