Omniphobic surfaces could be used in everything from ship hulls that reduce drag and increase efficiency to coverings that resist stains and protect against damaging chemicals. These surfaces may be self-cleaning, corrosion-resistant, heat-transfer enhancing, stain-resistant or resistant to mineral- or biofouling. Most reported omniphobic surfaces use texture, lubricants, and/or grafted monolayers to engender these repellent properties.

But the problem with omniphobic surfaces is that the Condensation can quickly disable their liquid-shedding properties. To overcome this drawback, MIT scientists are creating a surface structure that radically lessens the impacts of condensation, in spite of the fact that at a slight sacrifice in performance.

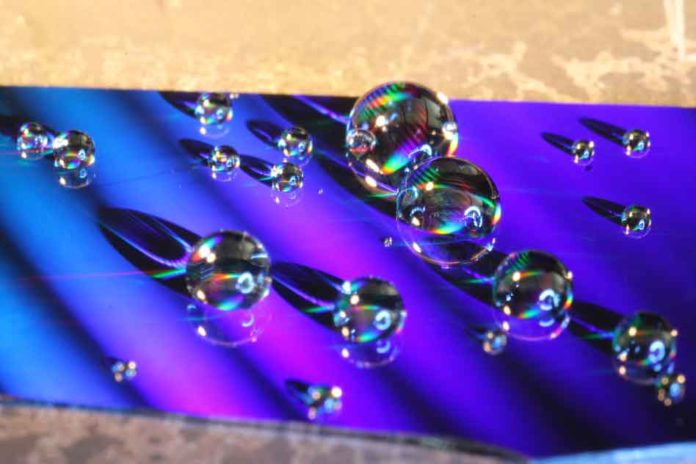

Such a surface can shed virtually all liquids and requires a precise kind of texture that creates an array of microscopic air pockets separated by pillars or ridges. These air pockets keep most of the liquid away from direct contact with the surface, preventing it from “wetting” or spreading out to cover a whole surface. Instead, the liquid beads up into droplets.

Various scientists are working on fabrication methods, but with surface highlights estimated in several microns (millionths of a meter) or less, it can be difficult to create and make the surfaces very delicate.

Graduate student Kyle Wilke said, “If such surfaces are damaged — for example, if one of the tiny pillars is bent or broken — it can defeat the whole process. One local defect can destroy the entire surface’s ability to repel liquids. And condensation, such as dew forming because of a temperature difference between the air and the surface, acts similarly, destroying the oleophobicity.”

“We considered: How can we lose some of the repellency but make the surface robust” against both damage and dew? We wanted a structure that one defect wouldn’t destroy. After much calculation and experimentation, they found a geometry that meets that goal thanks, in part, to microscopic air pockets that are disconnected rather than connected on the surfaces, making spreading between pockets much less likely.”

Scientists developed the architecture based on ridges whose profiles resemble a letter T, or in some cases, a letter T with serifs (the tiny hooks at the ends of letter strokes in some typefaces). Both the shape itself and the spacing of these ridges are important to achieving the surface’s resistance to damage and condensation.

They designed the shapes to use the surface tension of the liquid to prevent it from inserting the tiny surface pockets of air. The way the ridges connect prevents any local penetration of the surface cavities from spreading to others nearby.

Scientists constructed these ridges using standard microchip manufacturing systems. They initially etched the surfaces between ridges, then coated the edges of the pillars, then etched away those coatings to create the indentation in the ridges’ sides, leaving a mushroom-like overhang at the top.

Chang-Jin Kim, a professor of mechanical and aerospace engineering at the University of California at Los Angeles who was not involved in this work, says, “One of the most significant limitations of omniphobic surfaces is that, while such a surface has a superior liquid repellency, the entire surface is wetted once the liquid gets into the voids in the textured surface at some locations. This new approach addresses this very limitation.”

“I like that their key idea was based on fundamental science, while their goal was to solve a key real-life problem. The problem they addressed is an important but very difficult one.” And, he says, “This approach can potentially make some of the omniphobic surfaces useful and practical for some important applications.”

The new findings are described in the journal ACS Nano.