About 40 million tonnes of chicken feathers are burned annually. Along with the significant CO2 emissions, this also produces hazardous gasses like sulfur dioxide. The vast volume, cheap cost, renewability, biodegradability, and inherent material qualities of biobased industrial byproducts, such as side streams from the food sector, make them appealing alternatives with a strong potential for valorization.

Researchers at ETH Zurich and Nanyang Technological University Singapore (NTU) have now found a way to put these feathers to good use. They demonstrate the reutilization of industrial chicken feather waste into proton-conductive membranes for fuel cells, protonic transistors, and water-splitting devices.

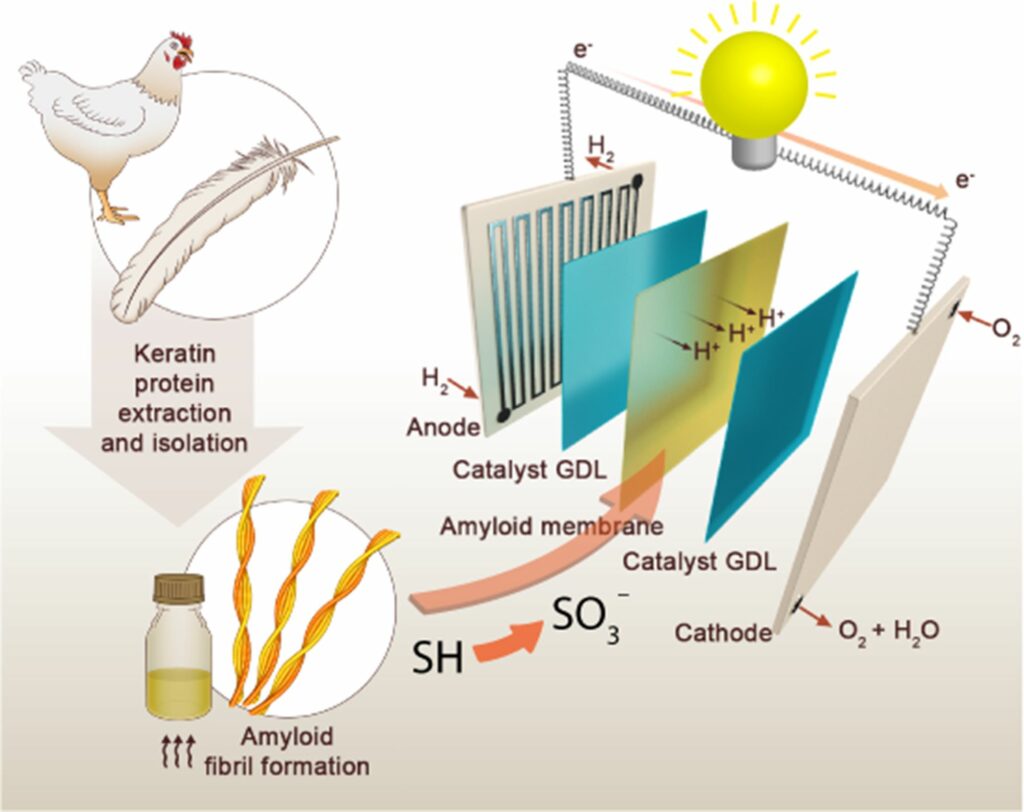

Using a straightforward and environmentally friendly procedure, they extract the protein keratin from the feathers and transform it into highly tiny fibers known as amyloid fibrils. These keratin fibrils are subsequently utilized in the fuel cell membrane.

Fuel cells release only heat and water while generating CO2-free energy from hydrogen and oxygen. In the future, they might be crucial as a sustainable energy source. Every fuel cell has a semipermeable membrane at its core. The electrons are forced to travel through an external circuit from the negatively charged anode to the positively charged cathode to produce an electric current. It permits protons to pass through but prevents electrons.

Membranes in conventional fuel cells consist of highly toxic chemicals, or “forever chemicals,” which are expensive and don’t break down in the environment. The new membrane developed in this study consists mainly of biological Keratin. This Keratin is environmentally compatible and available in large quantities – chicken feathers are 90 percent keratin. This makes the membrane up to three times cheaper than conventional membranes.

Raffaele Mezzenga, Professor of Food and Soft Materials at ETH Zurich said, “Our latest development closes a cycle: we’re taking a substance that releases CO2 and toxic gases when burned and using it in a different setting: with our new technology, it not only replaces toxic substances but also prevents the release of CO2, decreasing the overall carbon footprint cycle.”

“Hydrogen is the most abundant element in the universe – unfortunately not on Earth. Since hydrogen doesn’t occur here in its pure form, it has to be produced, which requires a great deal of energy. Here, too, the new membrane could serve well in the future because it can be used in fuel cells and water splitting.”

In electrolysis, water is exposed to a direct current, which causes oxygen to develop at the negatively charged cathode and hydrogen to escape at the positively charged anode. Adding acids is frequently necessary because pure water is insufficiently conductive for this procedure. However, the new membrane is proton permeable and permits particle migration between anode and cathode, which is required for adequate water splitting even in pure water.

Scientists isolated Keratin from chicken feathers via a fast and economical process in this study. They then converted them into amyloid fibrils through heat treatment and further processed them into membranes with an imparted proton conductivity using a simple oxidative method.

Scientists’ next step is to investigate how stable and durable their keratin membrane is and to improve it if necessary.

Journal Reference:

- Soon WL, Peydayesh M, de Wild T, Donat F, Saran R, Müller CR, Gubler L, Mezzenga R, Miserez A: Renewable Energy from Livestock Waste Valorization: Amyloid-Based Feather Keratin Fuel Cells. ACS Appl. Mater. Interfaces, September 26, 2023, DOI: 10.1021/acsami.3c10218