Prototyping physical user interfaces is essential for product designers and researchers to:

- Explore new user interface designs,

- Test an interactive system in practical use cases, and

- Study the interaction between humans and technology.

Building such interactive prototypes often requires integrating various electronic components, including sensors, speakers, displays, and other input/output components, into physical objects that can be curved or made of deformable materials.

Breadboard is a popular or rapid prototyping of such electronics. While traditional breadboards support traditional circuit prototyping, where the positioning on the prototype does not matter, they do not support interaction prototyping well, where the main focus is on positioning and testing input and output components on the prototype’s surface.

In a new study, MIT researchers reported about Flexboard, a flexible breadboard with upwards and downwards bending capability for prototyping on curved and deformable surfaces. This Flexboard allows rapid prototyping of objects with interactive sensors, actuators, and displays on curved and deformable surfaces, such as a ball or clothes.

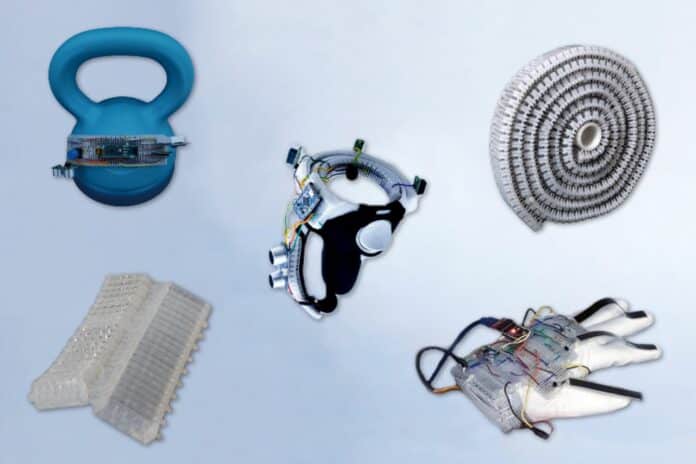

Researchers tested the platform on gloves, video game controllers, and kettlebells to show its adaptability to diverse objects. They discovered that sensors and displays could be attached to the electronic components of each platform’s hinges. The team equipped the kettlebells with sensors and LEDs to identify whether users were performing their swing exercises properly. The display then showed the number of repeats, red for improper execution and green for proper execution. By giving such feedback, the platform may help workout regimens improve.

To increase flexibility, a thin plastic links two pieces of the same material in the breadboard design. The spines of plastic disc cases and condiment bottle caps use this “living hinge pattern” to hold the electronic parts of FlexBoard together. An off-the-shelf 3D printer can reproduce the design and create FlexBoards that can be sewed to a product or fastened with epoxy glue or Velcro tape.

To enable FlexBoard’s bending capabilities, scientists replaced the traditional rigid breadboard body with a living hinge structure, which reversibly bends in both directions. To maintain electronic prototyping capabilities with standard pin spacing, they inserted the metal strips of the traditional breadboard into the individual hinges of the FlexBoard.

Thus, FlexBoard works like a traditional breadboard with the added capability of bending both up and down by 360° with only 30 segments (FlexBoard length: 7.62cm). While the pin distance changes when a FlexBoard is bent, the technical evaluation shows that components with up to 5 parallel pins can be inserted into a fully bent FlexBoard.

The team evaluated FlexBoard’s durability by bending it 1,000 times. They found that the breadboards remained fully functional without breaking afterward.

Research author Michael Wessely, a recent postdoc at the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL), said, “A fundamental development in our modern world is that we can interact with digital content everywhere and anytime, enabled through ubiquitous interactive devices. FlexBoard supports the design of these devices by being a versatile and rapid interactive prototyping platform. Our platform also enables designers to quickly test different sensors, displays, and other interactive components configurations, which might lead to faster product development cycles and more user-friendly and accessible designs.”

Junyi Zhu, an MIT Ph.D. electrical engineering and computer science student and a CSAIL affiliate, said, “The platform’s adaptability to different surfaces can streamline the electronic prototyping process. While designing new interactive devices, user interfaces, or most electronic products, we usually treat the object form and electronic functions as two separate tasks, which makes it hard to test the prototype in its use environment in the early stage and can lead to integration issues further down the road.”

“FlexBoards tackle these issues with enhanced, reusable flexible breadboards, which accelerate the current interactive device prototyping pipeline, and provide a new and valuable prototyping platform for the low-power electronics design and DIY [do-it-yourself] community.”

In the future, FlexBoard could make workout equipment, kitchen tools, furniture, and other household items more interactive. Still, the team acknowledges that their platform needs to be further optimized, requiring improved bendability, durability, and strength through multi-material printing.

Journal Reference:

- Donghyeon Ko, Yoonji Kim, Junyi Zhu, Michael Wessely, Stefanie Mueller. FlexBoard: A Flexible Breadboard for Interaction Prototyping on Curved and Deformable Surfaces. Paper