Water distinguishes our planet compared to all the others we know about. While the global supply of available freshwater is more than adequate to meet all current and foreseeable water demands, its spatial and temporal distributions are not. There are many regions where our freshwater resources are inadequate to meet domestic, economic development and environmental needs.

In such regions, the lack of adequate clean water to meet the human drinking water and sanitation needs is indeed a constraint on human health and productivity and hence on economic development as well as on the maintenance of a clean environment and healthy ecosystems.

According to UNESCO figures from 2012, almost 700 million people suffer from limited access to water – and that number could rise to 1.8 billion by 2025.

The desalination and the treatment of industrial wastewater can produce large amounts of drinking water, and these methods are already used in many countries and regions such as the United Arab Emirates, Saudi Arabia, China, Europe, and the USA.

But the drawback of those systems: 1. They are extremely costly and 2. Requires high energy.

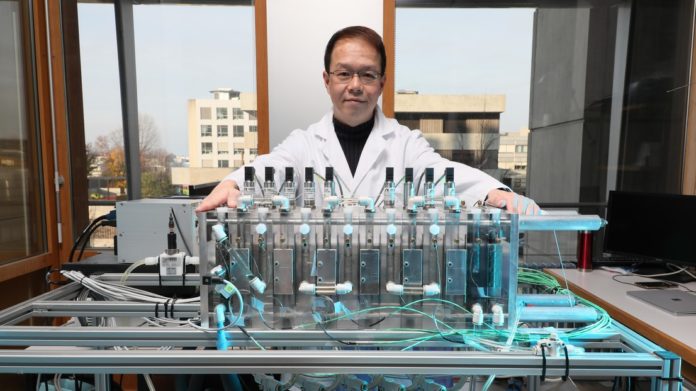

Now, Jeff Ong, from EPFL’s Laboratory of Inorganic Synthesis and Catalysis,

has found a solution by developing a water treatment machine that removes more than 99.9% of the salt from seawater with the same throughput but using less energy. The system offers the benefits of all of the main technologies currently being used while offering improved performance.

In Reverse Osmosis filters, large-scale desalination technology is used. It works by using a high-pressure pump to increase the pressure on the salt side of the RO and force the water across the semi-permeable RO membrane, leaving almost all (around 95% to 99%) of dissolved salts behind in the reject stream.

The amount of pressure required depends on the salt concentration of the feed water. The more concentrated the feed water, the more pressure is required to overcome the osmotic pressure.

The technique uses a relatively large amount of electricity (around 4–5 kWh/m3) and the membranes deteriorate rapidly, as do other components, worn down by mineral particles. They need to be chemically cleaned several times per year and replaced very frequently.

Ong said, “That results in high maintenance costs for producers. The desalination concept I used spin-off use membranes made of an inert hydrophobic material, wear out less quickly and can be recycled cheaply.”

How does the system work?

Ong put together a series of evaporation-based desalination modules to maximize salt separation. Again, to address the system’s main weakness – energy consumption – he made several improvements including internal heat recovery and more efficient heat transfer. By reducing the pressure, the water can be brought to a boil at a temperature of less than 80°C.

The vapor produced is cooled and recovered as fresh water. The rest of the liquid, which contains the remaining salt, passes into another cell with even lower pressure, and so forth. Heat recovery elements are used to pre-heat and vaporize the remaining saltwater, without using any energy from outside the system.

At each stage, the vapor produced is cooled and the resulting fresh water is recovered. The fresh water is removed using heat exchanger devices that are positioned so as to cool the system. By reusing heat that would otherwise be lost, E-METS has a much lower carbon footprint than a conventional thermal system.

As Ong noted, the system can potentially handle very high salt concentrations – more than 200 g/l – which is twice as much as standard thermal separation technologies and more than four times as much as reverse osmosis.

As well as being used to desalinate seawater, the system can be connected to reverse osmosis plants, helping them to produce higher volumes of desalinated drinking water.