Syngas, also known as synthetic gas- created by a variety of different materials that contain carbon. The photoelectrochemical (PEC) production of syngas from water and CO2 represents an attractive technology towards a circular carbon economy. However, high potential, low selectivity, and cost of commonly employed catalysts pose challenges for this sustainable energy-conversion process.

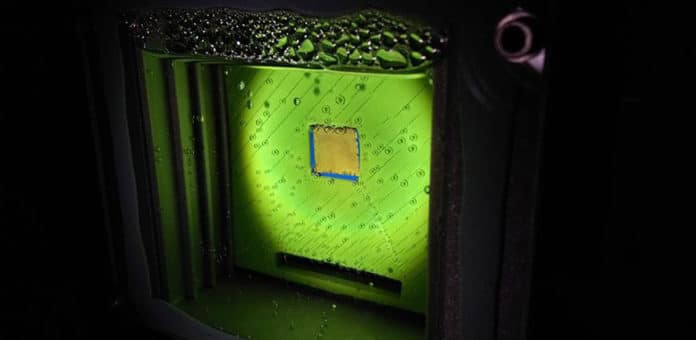

Developed by the University of Cambridge, an artificial leaf is an alternative to produce syngas and sustainable liquid fuel. Powered by sunlight, the leaf functions efficiently even in the cloudy and overcast days. And as compared to current industrial processes for producing syngas, the device does not release any additional carbon dioxide into the atmosphere.

Senior author Professor Erwin Reisner from Cambridge’s Department of Chemistry said, “Being able to produce it sustainably would be a critical step in closing the global carbon cycle and establishing a sustainable chemical and fuel industry.”

This artificial leaf is equipped with two light absorbers with a catalyst made from the naturally abundant element cobalt. After immersing with water, one light absorber uses the catalyst to produce oxygen while others carry out the chemical reaction that reduces carbon dioxide and water into carbon monoxide and hydrogen, forming the syngas mixture.

Scientists also used cobalt as their molecular catalyst, instead of platinum or silver. Cobalt is not only lower-cost, but it is better at producing carbon monoxide than other catalysts.

Reisner said, “What we’d like to do next, instead of first making syngas and then converting it into liquid fuel, is to make the liquid fuel in one step from carbon dioxide and water.”

“Although great advances are being made in generating electricity from renewable energy sources such as wind power and photovoltaics. The development of synthetic petrol is vital, as electricity can currently only satisfy about 25% of our total global energy demand.”

The research was carried out in the Christian Doppler Laboratory for Sustainable SynGas Chemistry in the University’s Department of Chemistry. It was co-funded by the Austrian government, the Austrian petrochemical company OMV, the Winton Programme for the Physics of Sustainability, the Biotechnology and Biological Sciences Research Council, and the Engineering and Physical Sciences Research Council.

The results are reported in the journal Nature Materials.