While electric vehicles (EVs) have gained a lot of popularity in the transportation sector, the idea of using hydrogen as a clean and efficient fuel has been around for decades. One of the advantages of hydrogen-powered vehicles is that they emit only water on combustion, making them a great option for reducing emissions. Moreover, hydrogen-based engines can be built on existing vehicle production lines, so they are expected to have a smaller manufacturing carbon footprint than EVs.

However, storing and transporting hydrogen presents some challenges, requiring energy-intensive processes such as high-pressure and low-temperature conditions. To address this, ammonia has been considered a potential carrier of hydrogen for fuel cells or combustion engines. Nevertheless, ammonia is a fuel that is difficult to burn efficiently and requires mixing with gasoline for optimal combustion.

Professor Mitsuhisa Ichiyanagi from the Department of Engineering and Applied Sciences at the Faculty of Science and Technology at Sophia University, along with Emir Yilmaz and Takashi Suzuki, also from Sophia University, has been working on developing engines that can run solely on ammonia without gasoline since 2019. This could be a significant step towards more sustainable transportation, as ammonia is a cleaner fuel source than gasoline and produces fewer emissions.

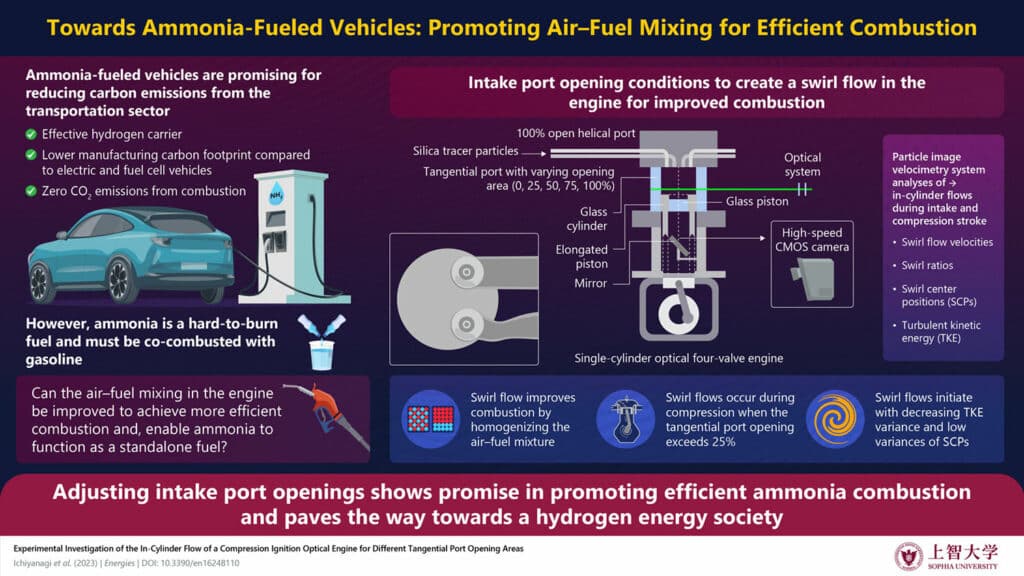

Their idea is to optimize the intake port opening conditions that enhance the mixing of air with fuel inside the engine cylinder for more efficient combustion. In a study, the researchers reported different intake port opening conditions that would lead to swirling flow conditions within the engine cylinder, enhancing combustion efficiency and reducing emissions.

“Airflow within cylinders profoundly affects combustion and emissions by influencing the air–fuel mixing phenomenon,” says Prof. Ichiyanagi. “With the aim of burning only ammonia, we have basically investigated the relationship between the engine’s intake system and the flow inside cylinders.”

Swirling flow is a vortex-like air–fuel mixture pattern entering the engine’s cylinder. It can positively impact engine performance by improving the mixing of air and fuel, which can lead to better combustion and decreased emissions. The researchers studied this phenomenon in an optical single-cylinder diesel engine with a glass cylinder and piston. To achieve this swirling flow, the engine used conventional tangential and helical intake ports for air intake.

The researchers used tiny silica particles as tracers and monitored their movement in the engine with a high-speed CMOS camera to visualize air flows during the intake stroke. They found that air entering through the helical port formed swirling patterns, while air from the tangential port initially did not produce any vortical structure. However, it eventually generated swirling structures when redirected by the cylinder walls.

In their earlier experiments, the researchers observed that airflow velocity remained relatively constant across various helical port openings. They experimented with different combinations of intake port openings, leaving the helical port completely open and varying the tangential port to 0 %, 25%, 50%, 75%, and 100%. This helped them determine its effect on intake and in-cylinder flows during the intake and compression strokes.

The study found that generating swirl flows in the engine during the compression stroke was successful when the tangential port was open by more than 25%. The researchers also noted that the formation of swirl flows correlated with low variances of turbulent kinetic energy during the intake stroke and low variances of the swirl center position during the compression stroke.

The discovery of swirl flows in the cylinder presents an opportunity for more efficient ammonia combustion in the engine. Moving forward, the researchers plan to use these findings to further investigate the combustion characteristics of an ammonia-gasoline mixture or ammonia alone within the engine.

The increasing demand for lithium, driven by the rise of EVs, is expected to reach over 2.4 million metric tons by the 2030s. However, the current production rate of 130,000 metric tons in 2022 may not be sufficient to meet the growing demand, resulting in potential lithium shortages as early as 2025, according to the International Energy Agency.

As a potential solution, while there are still challenges to overcome before ammonia-fueled vehicles become a reality, this research is promising for achieving decarbonization goals both now and in the future.

“The development of ammonia-fueled engine vehicles is expected to not only reduce carbon dioxide emissions from engines but also contribute to realizing a hydrogen energy society,” says Prof. Ichiyanagi.

Journal reference:

- Mitsuhisa Ichiyanagi, Emir Yilmaz, Kohei Hamada, Taiga Hara, Willyanto Anggono, and Takashi Suzuki. Experimental Investigation of the In-Cylinder Flow of a Compression Ignition Optical Engine for Different Tangential Port Opening Areas. Energies, 2023; DOI: 10.3390/en16248110