Micromotors have shown great promise in the field of environmental remediation due to their ability to navigate autonomously and perform specific tasks at the microscale. These tiny machines can be designed to move through wastewater and target specific contaminants. Self-propelled micromotors can carry functional materials or coatings that can adsorb or react with pollutants, helping to effectively remove them from the water.

Now, researchers from the Institute of Chemical Research of Catalonia (ICIQ) have designed micromotors that move around on their own to purify wastewater and produce ammonia, which can serve as a green energy source.

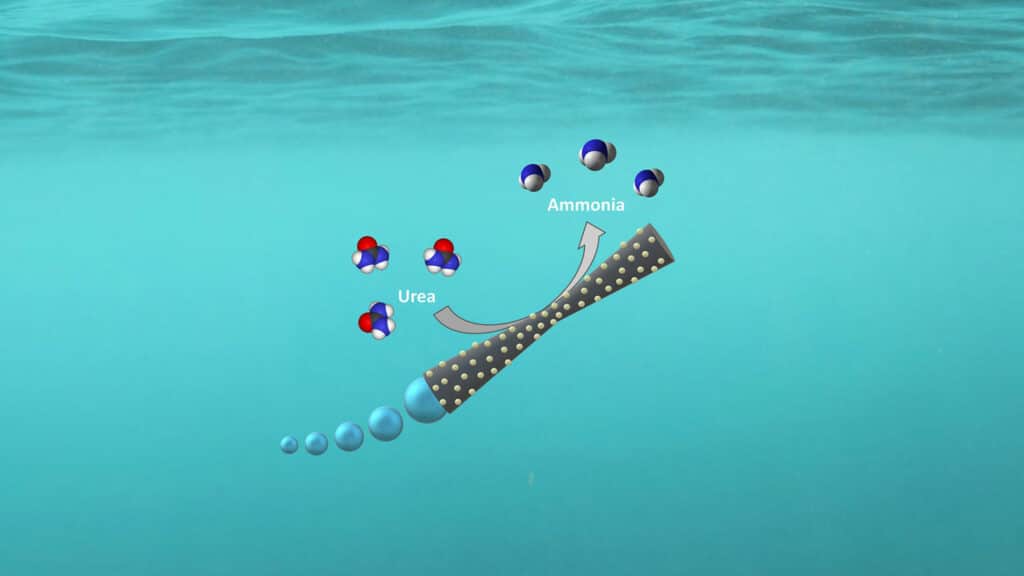

These hybrid tubular micromotors combine sol-gel and hydrothermal reactions, utilizing silica as the scaffold and coating it with a manganese dioxide (MnO2) layer. In the silicon and manganese dioxide tube, chemical reactions cause the release of bubbles from one end. These bubbles act as a motor that sets the tube in motion.

To enhance their catalytic efficiency in degrading organic pollutants, such as RB and urea, researchers further functionalized the surface of the micromotors with laccase, the bio-catalytic counterpart, for the generation of ammonia from urea. Urea is an emerging contaminant, being a common pollutant from residential activities (urea is the main component of urine) and from different industrial processes.

The chemical component laccase accelerates the conversion of urea into ammonia upon contact with contaminated water. This ammonia can be transformed into hydrogen, which is a clean and sustainable energy source.

“This is an interesting discovery. Today, water treatment plants have trouble breaking down all the urea, which can result in eutrophication when the water is released. This is a serious problem in urban areas in particular,” says Rebeca Ferrer, a PhD student from Dr. Katherine Villa’s group at ICIQ.

Converting urea into ammonia can remove the pollutant but offers other advantages as well. Ammonia is becoming increasingly important as a source of green energy, as it can be decomposed to produce hydrogen and stored as a green fuel. Despite these benefits, researchers faced several challenges during the development of this research, such as the production of bubbles by the micromotors.

“We need to optimize the design so that the tubes can purify the water as efficiently as possible. To do this, we need to see how they move and how long they continue working, but this is difficult to see under a microscope because the bubbles obscure the view,” Ferrer explains in a statement.

A machine learning method developed by researchers at the University of Gothenburg will be used to estimate the movements of the micromotors. It will also enable several motors in the liquid to be monitored simultaneously.

This approach provides valuable insights into the motion and behavior of micromotors, enabling their precise control and monitoring. It also represents a promising alternative approach towards the development of biocatalytic micromotors for generating green energy fuels.

Despite its potential, the scientists are unsure about the timeline for the large-scale deployment of their devices. For now, they continue to work towards making this innovation universally viable in the coming years.

Journal reference:

- Rebeca Ferrer Campos, Harshith Bachimanchi, Giovanni Volpe, and Katherine Villa. Bubble-propelled micromotors for ammonia generation. Nanoscale, 2023; DOI: 10.1039/D3NR03804A