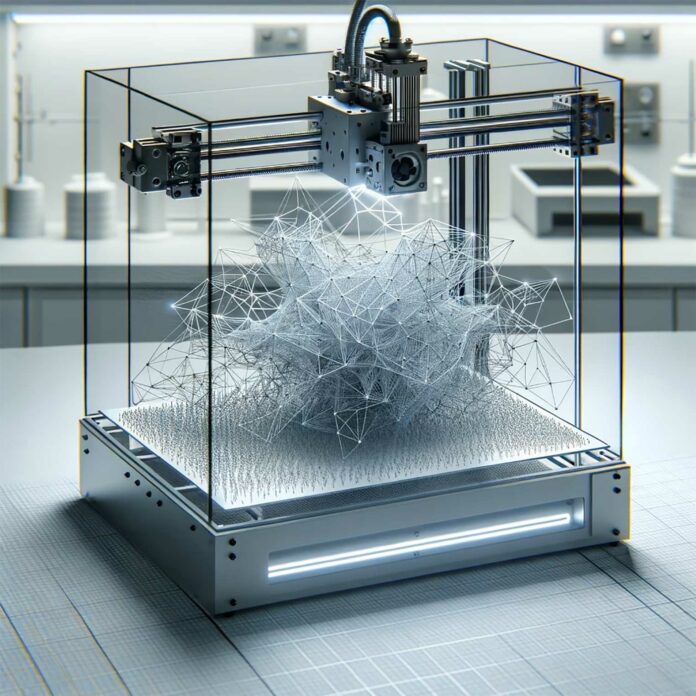

The practical use of mechanical metamaterials often involves solving inverse problems to find the ideal microarchitectures that result in desired properties. However, additive manufacturing techniques have limited resolution. It needs to solve inverse problems for specific sizes of specimens.

Additionally, the microarchitectures must be resistant to fatigue and fracture. Solving these multi-objective inverse design problems is exceptionally challenging. But, its solution is the key to real-world applications of mechanical metamaterials.

In a new study, researchers from TU Delft have now developed an AI tool that can discover such extraordinary materials and make them fabrication-ready and durable. Their approach is like this: Tell us what you want as properties, and we will engineer an appropriate material with those properties. The resulting material will be a metamaterial with unprecedented functionalities.

First author Dr. Helda Pahlavani said, “Even when inverse problems were solved in the past, they have been limited by the simplifying assumption that the small-scale geometry can be made from an infinite number of building blocks. The problem with that assumption is that metamaterials are usually made by 3D printing and real 3D printers have a limited resolution, which limits the number of building blocks that fit within a given device.”

The new AI model bypasses any such simplifying assumptions.

How many building blocks does your manufacturing technique allow you to accommodate in your device? The model then finds the geometry that gives you your desired properties for the number of building blocks that you can actually manufacture.”

Indeed, durability is a critical practical concern often overlooked in previous research on metamaterials. Many existing designs tend to break down after being used only a few times because of durability.

This new study considers durability and selects the most durable designs from a large pool of design candidates, making the designs practical and not just theoretical adventures.

Assistant professor Mohammad J. Mirzaali, the publication’s corresponding author, said, “The possibilities of metamaterials seem endless, but the full potential is far from being realized. This is because finding the optimal design of a metamaterial is currently still largely based on intuition, involves trial and error, and is therefore labor-intensive.”

“Using an inverse design process, where the desired properties are the starting point of the design, is still very rare within the metamaterials field. But we think the step we have taken is revolutionary in metamaterials. It could lead to all kinds of new applications. There are possible applications in orthopaedic implants, surgical instruments, soft robots, adaptive mirrors, and exo-suits.”

Journal Reference:

- Helda Pahlavani, Kostas Tsifoutis-Kazolis et al. Deep Learning for Size-Agnostic Inverse Design of Random-Network 3D Printed Mechanical Metamaterials. Advanced Materials. DOI: 10.1002/adma.202303481