Additive manufacturing (AM), often seen as an eco-friendly alternative to traditional manufacturing, is praised for its efficient use of materials, reduced waste, and ability to incorporate intricate designs. While AM has made strides in various materials like polymers and ceramics, its application with metals has faced challenges in scalability.

Metal additive techniques have typically been associated with high costs, making them more common in the aerospace and automotive industries. Despite this, the global production of metal parts, particularly steel and aluminum, remains among the most energy-intensive processes.

In architecture and construction, welding arc additive manufacturing is one of the few metal techniques capable of creating large-scale parts, although slow printing speeds constrain it.

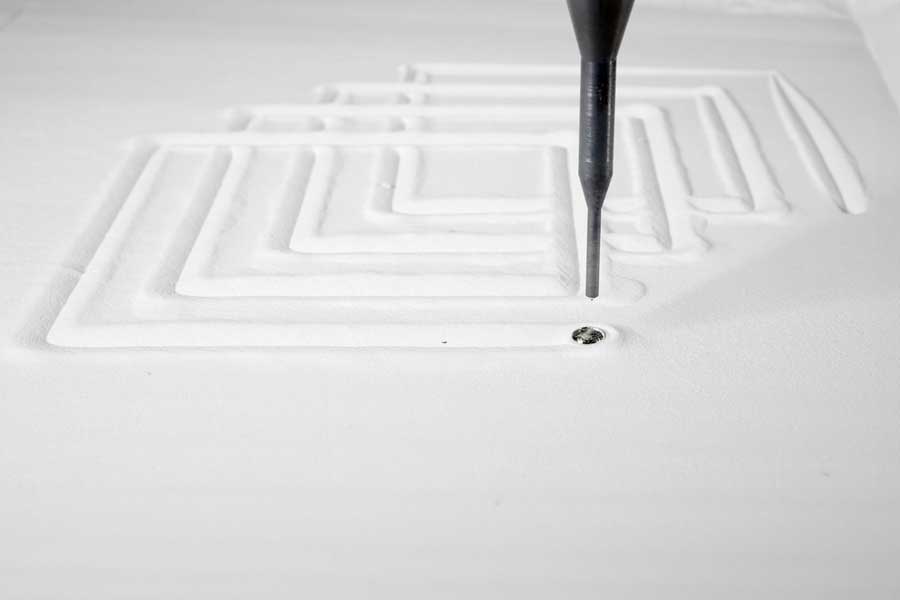

MIT researchers have introduced a novel additive manufacturing method known as liquid metal printing (LMP), which is capable of swiftly 3D printing large-scale parts such as table legs and chair frames within minutes. In this process, molten aluminum is carefully deposited along a pre-defined path into a bed of tiny glass beads. The aluminum solidifies rapidly, forming a sturdy 3D structure.

Liquid Metal Printing (LMP) boasts a speed advantage, at least ten times faster than comparable metal additive manufacturing methods. Additionally, the process of heating and melting the metal is more efficient compared to some other techniques. However, LMP makes a trade-off between speed and resolution. While it excels at producing larger components more quickly and cost-effectively, it cannot achieve the high solutions achievable with slower additive manufacturing methods.

The technique is well-suited for architecture, construction, and industrial design applications, where more details may be needed for larger structures. LMP can also be effectively utilized for rapid prototyping, especially with recycled or scrap metal. In a recent study, researchers demonstrated the capabilities of LMP by printing aluminum frames and components for tables and chairs, showcasing their strength even after post-print machining.

Skylar Tibbits, associate professor in the Department of Architecture and co-director of the Self-Assembly Lab, senior author of a paper introducing LMP, said, “This is a completely different direction in how we think about metal manufacturing that has some huge advantages. It has downsides, too. But most of our built world — the things around us like tables, chairs, and buildings — doesn’t need extremely high resolution. Speed, scale, repeatability, and energy consumption are all important metrics.”

Leveraging their prior expertise in rapid liquid printing with rubber, the researchers developed a specialized machine. This machine is designed to melt aluminum, contain the molten metal, and dispense it through a nozzle at high speeds. Large-scale parts can be printed in seconds, and the molten aluminum solidifies within a few minutes. This rapid liquid printing process allows for the swift creation and cooling of sizable aluminum structures, showcasing the efficiency and speed of the developed technology.

Lead author Zain Karsan SM ’23 said, “Our process rate is high, but it is also tough to control. It is more or less like opening a faucet. You have a big volume of material to melt, which takes some time, but once you get that to melt, it is like opening a tap. That enables us to print these geometries very quickly.”

The choice of aluminum for this printing technique was motivated by its widespread use in construction and its cost-effective and efficient recycling processes.

The process involves placing pieces of aluminum, roughly the size of a bread loaf, into an electric furnace resembling an upscaled toaster. Metal coils within the stove heat the aluminum to a temperature of 700 degrees Celsius, slightly above its melting point of 660 degrees Celsius.

Maintaining the aluminum at this elevated temperature within a graphite crucible, the molten material is gravity-fed through a ceramic nozzle into a print bed, following a predetermined path. Interestingly, the researchers discovered that the faster the printer could operate was directly linked to the amount of aluminum melted, highlighting the scalability of the printing process.

Karsan said, “Molten aluminum will destroy almost everything in its path. We started with stainless steel nozzles and then moved to titanium before we ended up with ceramic. But even ceramic nozzles can clog because the heating is not always entirely uniform in the nozzle tip.”

The researchers explored various materials to fill the print bed during their experiments, considering options like graphite powders and salt. Ultimately, they settled on 100-micron glass beads. These tiny glass beads can withstand the extremely high temperature of molten aluminum and serve as a neutral suspension, facilitating rapid cooling of the metal.

The glass beads, being excellent, have a texture akin to silk. Their small size ensures minimal alteration to the surface characteristics of the printed object. The geometry of the final thing is primarily influenced by factors such as the amount of molten material in the crucible, the depth of the print bed, and the size and shape of the nozzle.

The printing process starts with parts of the object with larger diameters, as the amount of aluminum dispensed by the nozzle tapers off with decreasing crucible levels. Adjusting the depth of the nozzle allows for control over the thickness of the printed metal structure.

The researchers created a numerical model to enhance the Liquid Metal Printing (LMP) process. This model helps estimate the quantity of material that will be deposited into the print bed at any given time during the printing process.

Due to the nature of the LMP process, where the nozzle penetrates the glass bead powder, direct observation of the molten aluminum deposition is not possible. Therefore, the researchers rely on the numerical model to simulate and understand the dynamics of the printing process at specific points. This modeling approach allows them to predict and optimize the behavior of the molten aluminum throughout the printing procedure.

The researchers successfully employed Liquid Metal Printing (LMP) to manufacture aluminum frames with variable thicknesses swiftly. These frames demonstrated durability and could withstand post-processing machining techniques such as milling and boring. In a practical application, the researchers showcased a combination of LMP and post-processing methods to create chairs and a table. These furniture pieces incorporated lower-resolution rapidly printed aluminum parts alongside other components like wood.

As they move forward, the researchers aim to refine the machine further. Their goals include ensuring consistent heating in the nozzle to prevent material from sticking and achieving better control over the flow of molten material. However, challenges still exist, especially with larger nozzle diameters potentially causing irregular prints. Addressing these technical challenges will be crucial for the continued improvement and broader application of the LMP technology.

Tibbits says, “If we could make this machine something that people could use to melt down recycled aluminum and print parts, that would be a game-changer in metal manufacturing. It is unreliable enough to do that right now, but that’s the goal.”

Jaye Buchbinder, who led business development for the furniture company Emeco and was not involved with this work, said, “At Emeco, we come from the world of very analog manufacturing, so seeing the liquid metal printing creating nuanced geometries with the potential for fully structural parts was compelling.”

“The liquid metal printing walks the line in terms of ability to produce metal parts in custom geometries while maintaining quick turnaround that you don’t normally get in other printing or forming technologies. There is potential for the technology to revolutionize the way metal printing and metal forming are currently handled.”

Journal Reference:

- Zain Karsan, Kimball Kaiser, Jared Laucks, et al. Liquid Metal Printing. Link to paper.