Using multiple materials that cost less than $3.89 per unit, MIT scientists have manufactured a new miniature pump by 3D printing. Fabricated within 75 minutes, the pump is compact, valveless, and operated magnetically.

It measures 1 centimeter in volume and can move both liquids and gases using less power and experiencing less clogging than standard manufactured pumps of this size. It could be used in applications “from fuel cells to power generation to heat exchangers” that cool computer chips.

Luis Fernando Velásquez-García, a principal research scientist at MIT‘s Microsystems Technology Laboratories (MTL), said, “the proof-of-principle pump will inspire others to look more closely at the potential of layer-by-layer, computer-aided additive manufacturing, compared to the “cleanroom” mass-production style set by the semiconductor industry.”

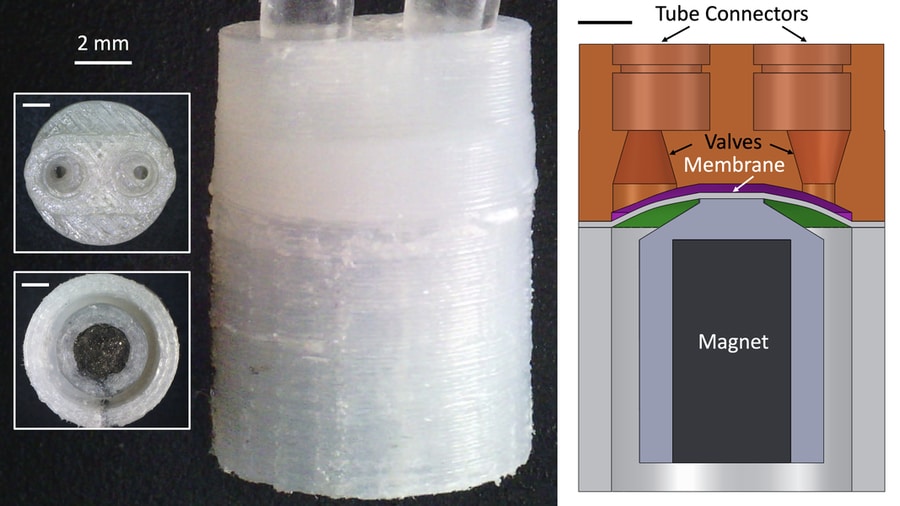

With a diameter of less than a dime, the pump comes in the shape of a cylinder crowned by a membrane. On top of the membrane is the fluid chamber, with two valveless ports at the top to attach tubes.

The miniature diaphragm pumps are fabricated using 150 μm-thick to 225 μm-thick layers via fused filament fabrication; the structural parts are printed in pure Nylon 12, while the magnet that makes possible the actuation of the pump chamber is either monolithically printed in Nylon 12 embedded with NdFeB micro-particles or press-fit into the pump after single-material printing of the enclosing piston.

With the second monolithic pump, the researchers used Nylon 12 embedded with neodymium magnet (NdFeB) microparticles to create the pump’s magnetic core.

The devices are driven by a rotating magnet and can deliver liquid flow rates as large as 7.88 ml revolutions per minute at 198 Hz for sintered magnet pumps. The outside rotating magnet interacts with the internal magnet to move the piston and deform the membrane—this propels liquid or gas from one port to the other.

The membrane only constrains the piston, so it can move in multiple ways at the same time when activated by the external magnet. Since it is magnetically driven, the new device is more portable than pneumatic pumps, which need to be physically coupled to an outside source of pressurized fluid.

Velásquez-García says the device demonstrates the opportunities available through monolithic, multi-material 3D printing.

“For instance, the researchers were able to increase the new pump’s stroke capacity beyond that of a pump classically manufactured in silicon by altering printing methods to make a more deformable membrane while keeping a more rigid piston body — all using the same Nylon 12 material.”

It’s not about copy-and-pasting what people have done before, it’s exploiting the advantages of printing,” says Velásquez-García. “I think there is a real opportunity to make a difference if we revisit problems that we couldn’t quite solve before, and now we can because of this umbrella of additive manufacturing.”

Albert Folch, a bioengineering professor at the University of Washington who was not involved in the MIT study, said, “The new magnetic pump is a very clever implementation of the principle that ‘complexity is free’ in digital and additive manufacturing. Because these pumps are made of several components of different materials and complex shapes, traditional manufacturing and assembly tend to be expensive.”

Velásquez-García said, “The possibilities of how to process energy and information are far greater if you can monolithically create devices that are made of a plurality of materials.”

Journal Reference:

- Anthony P Taylor et al. Compact, magnetically actuated, additively manufactured pumps for liquids and gases. DOI: 10.1088/1361-6463/ab8de8