Scientists at Rutgers University have created a new way to paint complex 3D-printed objects. This new way is effective as well as time and money saver and also offers complex 3D-printed objects.

Senior author Jonathan P. Singer, an assistant professor in the Department of Mechanical and Aerospace Engineering in the School of Engineering at Rutgers University-New Brunswick said, “Our technique is a more efficient way to coat not only conventional objects, but even hydrogel soft robots, and our coatings are robust enough to survive complete immersion in water and repeated swelling and de-swelling by humidity.”

Engineers discovered new abilities of a technology that makes a fine spray of droplets by applying a voltage to fluid flowing through a nozzle. This technique (electrospray statement) has been utilized fundamentally for analytical chemistry. Be that as it may, in recent decades, it has likewise been used in lab-scale demonstrations of coatings that deliver vaccines, light-absorbing layers of solar cells, and fluorescent quantum dots for LED displays.

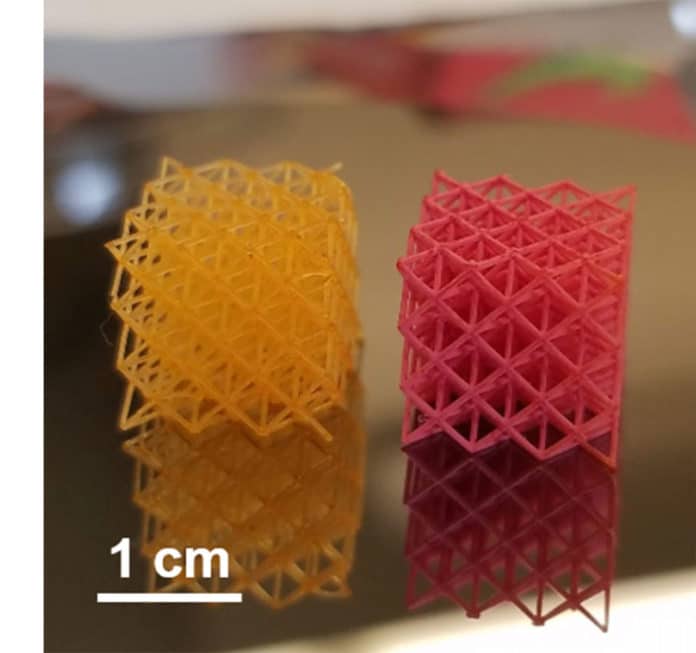

Using their approach, engineers built an accessory for 3D printers that will ted coating of 3D-printed parts with functional, protective, or aesthetic layers of paint.

Engineers noted, “The technique features much thinner and better-targeted paint application, using significantly fewer materials than traditional methods. That means engineers can use cutting-edge materials, such as nanoparticles and bioactive ingredients, that would otherwise be too costly in paints, according to Singer.”

Journal Reference:

- Dylan A. Kovacevich, Self-Limiting Electrospray Deposition for the Surface Modification of Additively Manufactured Parts. DOI: 10.1021/acsami.9b23544