Producing glass objects using 3-D printing is not easy. Until now, only a few groups of researchers were able to produce it by using additive methods.

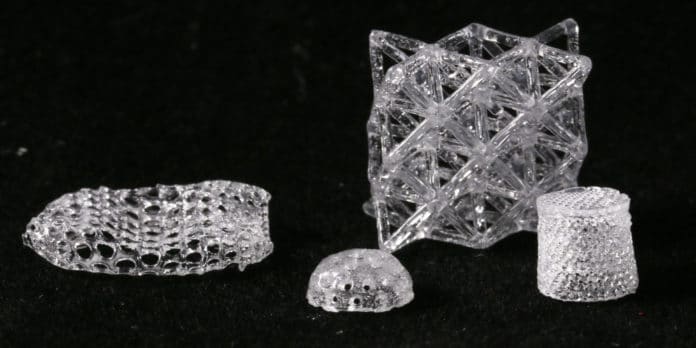

Recently, scientists from ETH Zurich have used a 3D printing process to produce complex and highly porous glass objects. They have used a new technique to produce complex glass objects with 3-D printing.

According to scientists, the method opens up novel opportunities to explore functionalities inaccessible by current technologies.

The new method is based on stereolithography, one of the first 3-D printing techniques developed during the 1980s.

Scientists have developed a special type of resin from plastic, and organic molecules to which glass precursors are bonded. The resin can be processed utilizing commercially available Digital Light Processing technology. This includes irradiating resin with UV light examples.

Wherever the light strikes the resin, it solidifies because of the light-sensitive components of the polymer resin cross link at the exposed points. The plastic monomers combine to form a labyrinth-like structure, creating the polymer. The ceramic-bearing particles fill the interstices of this labyrinth.

An object can thus be built up layer by layer. Even scientists can change the parameters in each layer.

Kunal Masania from the Complex Materials group said, “We discovered that by accident, but we can use this to influence the pore size of the printed object directly.”

Scientists also modified the microstructure, layer by layer. They mixed silica with borate or phosphate and adding it to the resin. Complex objects can be made from different types of glass, or even combined in the same object using the technique.

Scientists then fire the blank produced in this way at two different temperatures: at 600˚C to burn off the polymer framework and then at around 1000˚C to densify the ceramic structure into the glass. During the firing process, the objects shrink significantly but become transparent and hard like window glass.

Masania said, “These 3-D-printed glass objects are still no bigger than a die. Large glass objects, such as bottles, drinking glasses, or window panes, cannot be produced in this way—which was not the goal of the project.”

The researchers reported their results in the latest issue of the journal Natural Materials.