High-purity silicon makes up the majority of solar cells. However, they are typically discarded once they reach the end of their operational lifespan after 25 to 30 years.

Separating silicon from other components such as aluminum, copper, silver, lead, and plastic is a challenge. Moreover, recycling the silicon is also difficult due to impurities and defects, which make it unusable in other silicon-based technologies.

Conventional recycling methods to recover high-purity silicon are costly as they require a lot of energy and involve highly toxic chemicals. This makes them expensive and limits their widespread adoption among recyclers.

Researchers from Nanyang Technological University, Singapore (NTU Singapore) have come up with an efficient method of recovering high-purity silicon from expired solar panels for upcycling into lithium-ion batteries. This breakthrough can potentially solve the growing problem of solar panel waste and help meet the increasing global demand to power electric vehicles.

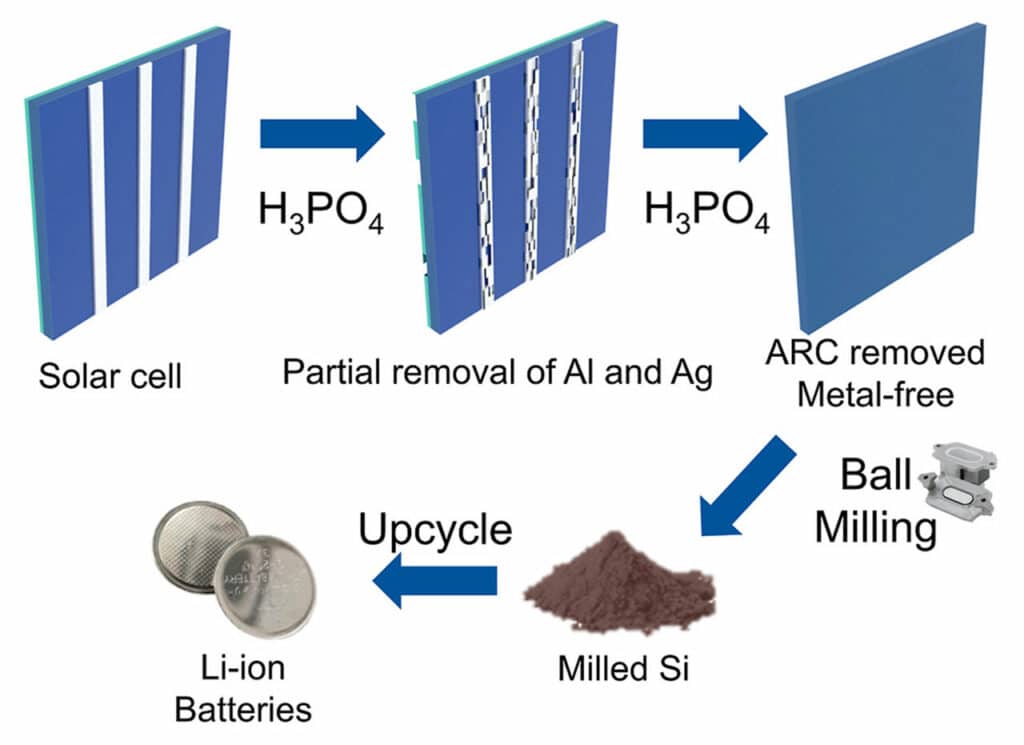

The new extraction method involves first soaking the expired solar cell in hot diluted phosphoric acid for 30 minutes to remove metals like aluminum and silver from their surfaces. This process is repeated using fresh phosphoric acid to ensure complete removal of the metals, resulting in a pure silicon wafer at the end of another 30 minutes.

Researchers used advanced spectroscopic analyses to evaluate the elemental content of the recovered wafer. They found that their sample achieved a recovery rate of 98.9% with a purity of 99.2%. These results are comparable to silicon recovered through currently available methods.

When the recovered silicon was upcycled into a lithium-ion battery anode and tested for efficiency, it showed the battery performance comparable to as-purchased silicon. High-purity silicon is necessary to reduce potential side reactions with lithium-ions that could negatively impact the battery’s performance.

The recovered silicon lithium-ion battery anodes demonstrated a high specific capacity of 1086.6 mAh g−1, even after 500 cycles at a high charging rate of 1.0C, while maintaining high coulombic efficiency (over 99%).

“The comparable performance between our upcycled silicon-based lithium-ion battery and the newly purchased ones proves that the NTU approach is feasible,” Dr Sim Ying, lead author of the study, said in a statement. “We envision our faster and cheaper silicon recovery method to be a positive boost for the development of EV batteries. Aside from EVs, there are also potential applications such as thermoelectric devices.”

Journal reference:

- Ying Sim, Yeow Boon Tay, Ankit, Xue Lin, Nripan Mathews. Simplified silicon recovery from photovoltaic waste enables high-performance, sustainable lithium-ion batteries. Solar Energy Materials and Solar Cells, 2023; DOI: 10.1016/j.solmat.2023.112394