Protective applications in extreme environments demand materials with superior modulus, strength, and specific energy absorption (SEA) at lightweight. They must also have the ability to attenuate intense stress waves and absorb kinetic energy from impact while providing thermally stable functionality.

A concussion can be brought on by the physical trauma that an impact can cause to the brain. Concussions and other traumatic brain injuries could be mitigated, or perhaps prevented, with helmet materials better at absorbing and dispersing this kinetic energy before it reaches the brain.

Engineers at the University of Wisconsin–Madison have developed a lightweight, ultra-shock-absorbing foam that could vastly improve helmets designed to protect people from strong blows.

The new material has a specific energy absorption that is 18 times higher than the foam currently used in combat helmet liners for the U.S. military and is stronger and stiffer, which may enable it to offer better impact protection.

The researchers’ industry partner, helmet manufacturer Team Wendy, is experimenting with the new material in a helmet liner prototype to investigate its performance in real-world scenarios.

Ramathasan Thevamaran, a UW–Madison professor of engineering physics who led the research, said, “This new material holds tremendous potential for energy absorption and thus impact mitigation, which in turn should significantly lower the likelihood of brain injury.”

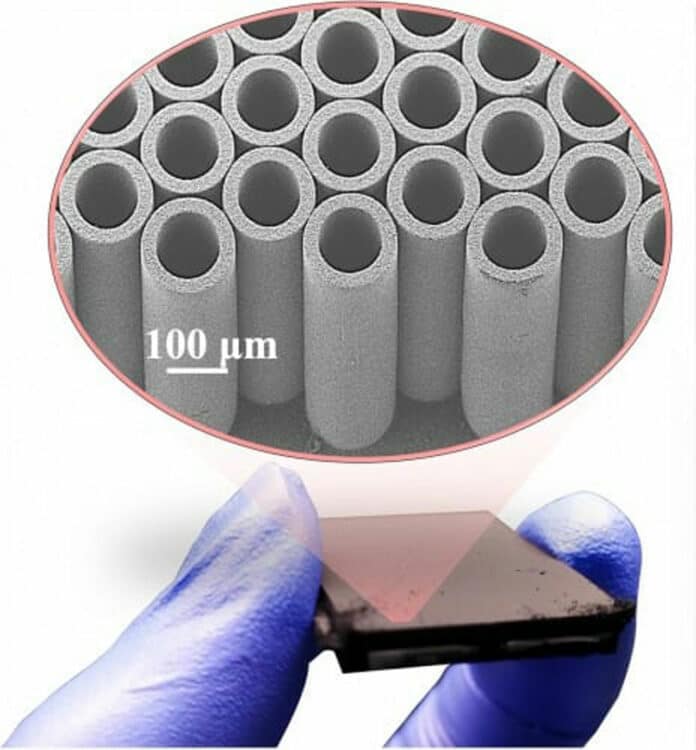

A foam made of vertically oriented carbon nanotubes is a novel substance. The fundamental building blocks used by the researchers to construct it were carbon nanotubes, which are carbon cylinders that are only one atom thick in each layer.

Since carbon nanotubes already possess outstanding mechanical capabilities, the researchers created a material with distinctive structural features at various length scales to improve its performance. Many micrometer-scale cylinder structures consisting of carbon nanotubes make up the material’s novel architecture.

It took time to determine the new foam’s ultimate optimal design criteria, which included cylinder thickness, inner diameter, and distance between adjacent cylinders. The researchers did the experimentation methodically, adjusted each parameter, and looked at every potential combination.

Thevamaran says, “So we took a few different thicknesses and then tested that with every diameter size and every possible gap, and so on. Altogether, we looked at 60 combinations and conducted three tests on each sample, so 180 experiments went into this study.”

They discovered an obvious winner. The best shock-absorbing foam was created by placing closely spaced cylinders with a thickness of 10 micrometers or less.

Thevamaran says, “I expected the overall properties to improve due to our interactive architecture, but I was surprised by how dramatically the properties were enhanced when the cylinders were 10 micrometers thick. It was due to an unusual size effect that emerged in the process-structure-property relations. The effect was very pronounced, and it was quite advantageous for the properties we were targeting.”

Journal Reference:

- Komal Chawla et al. Superior mechanical properties by exploiting size-effects and multiscale interactions in hierarchically architected foams. Extreme Mechanics Letters. DOI: 10.1016/j.eml.2022.101899