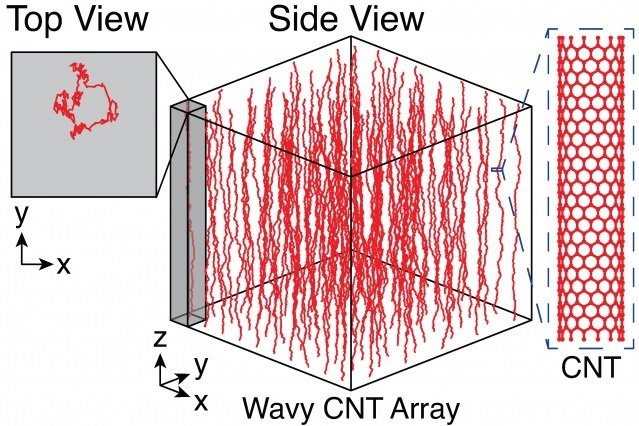

Carbon nanotubes (CNTs) into business applications, from coatings for airship wings to warm sinks for portable registering, expects them to be created in expansive scale and requiring little to no effort. Synthetic vapor affidavit (CVD) is a promising way to deal with make CNTs in the required scales, however, it produces CNTs that are excessively meager and agreeable for general applications.

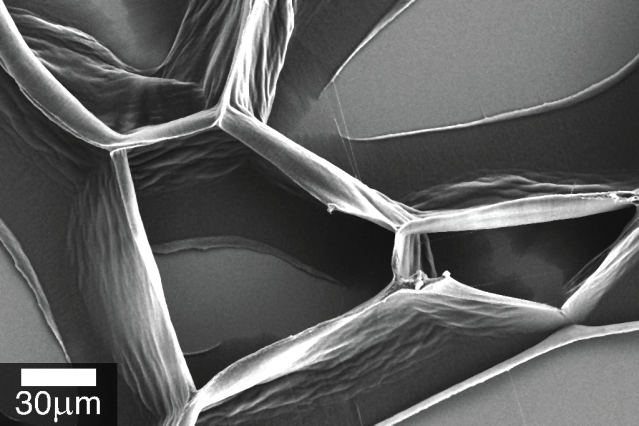

Applying and dissipating a couple of drops of a fluid, for example, CH3)2CO to the CNTs is a simple, financially savvy technique to all the more firmly pack them together and increment their solidness, however as of not long ago, there was no real way to conjecture the geometry of these CNT cells.

Image: Itai Stein/MIT

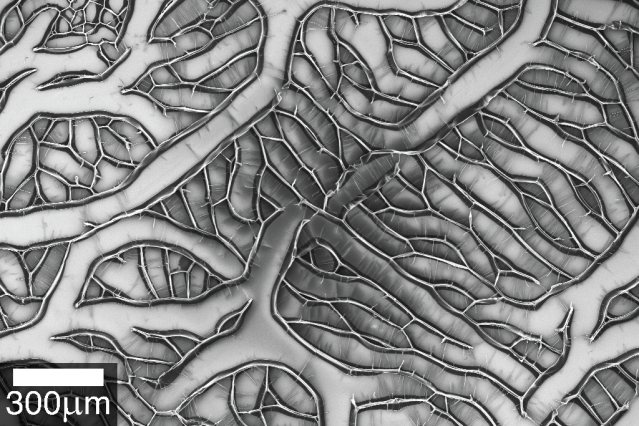

MIT specialists have now built up a precise technique to foresee the two-dimensional examples CNT clusters shape after they are pressed together, or densified, by vanishing drops of either CH3)2CO or ethanol.

CNT behavior can be thought by imagining how entangled fibers such as wet hair or spaghetti collectively reinforce each other. As large as this entangled region, the higher its resistance to bending itself.

Likewise, longer CNTs can better reinforce one another in a cell wall. The specialists likewise find that CNT binding strength to the base on which they are created, for this situation, silicon, makes a critical commitment to anticipating the cell designs that these CNTs will shape.

Itai Stein SM ’13, Ph.D. ’16, said, “These findings are directly applicable to the industry because when you use CVD, you get nanotubes that have curvature, randomness, and are wavy, and there is a great need for a method that can easily mitigate these defects without breaking the bank.”

Image: Ashley Kaiser/MIT

Senior author Brian Wardle said, “From our previous work on aligned carbon nanotubes and their composites, we learned that more tightly packing the CNTs is a highly effective way to engineer their properties. The challenging part is to develop a facile way of doing this at scales that are relevant to commercial aircraft (hundreds of meters), and the predictive capabilities that we developed here are a large step in that direction.”

Carbon nanotubes are highly desirable because of their thermal, electrical, and mechanical properties, which are directionally dependent. Earlier work in Wardle’s lab demonstrated that waviness reduces the stiffness of CNT arrays by as little as 100 times, and up to 100,000 times. The technical term for this stiffness, or ability to bend without breaking, is elastic modulus. Carbon nanotubes are from 1,000 to 10,000 times longer than they are thick, so they deform principally along their length.

The researchers used a heating technique to increase the adhesion of their original, undensified CNT arrays to their silicon wafer substrate. CNTs densified after heat treatment were about four times harder to separate from the silicon base than untreated CNTs.

The new work demonstrates that CNTs compacted by the capillary powers from first wetting them with acetone or ethanol and after that vanishing the fluid additionally delivers CNTs that are hundreds to thousands of times less hardened than anticipated by hypothetical esteems. This narrow impact, known as elastocapillarity, is like a how a wipe frequently dries into a more reduced shape in the wake of being wetted and after that dried.

Image: Ashley Kaiser/MIT

Stein said, “Our findings all point to the fact that the CNT wall modulus is much lower than the normally assumed value for perfect CNTs because the underlying CNTs are not straight. Our calculations show that the CNT wall is at least two orders of magnitude less stiff than we expect for straight CNTs, so we can conclude that the CNTs must be wavy.”

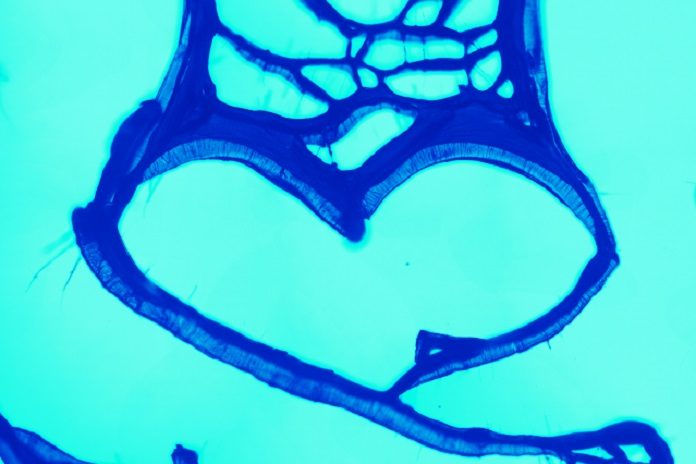

Engineering graduate student Ashley Kaiser said, “When we first started exploring densification methods, I found that this forceful technique densified our CNT arrays into highly unpredictable and interesting patterns. As seen optically and via SEM, these patterns often resembled animals, faces, and even a heart — it was a bit like searching for shapes in the clouds.”

“I think there is an underlying beauty in this nanofiber self-assembly and densification process, in addition to its practical applications. The CNTs densify so easily and quickly into patterns after simply being wet by a liquid. Being able to accurately quantify this behavior is exciting, as it may enable the design and manufacture of scalable nanomaterials.”

CNT cell size and wall stiffness grow proportionally with cell height, they report in the Feb. 14 issue of Physical Chemistry Chemical Physics.