Scientists at the University of Munich are working on a way to turn algae into diesel fuel. Of course, this will be the first technology to create environmentally-friendly diesel.

Algae has none of these disadvantages. Algae is typically grown in vats, and those vats can be placed pretty much anywhere. Algae is cheaper and faster to grow than either corn or soybeans, making it ideal for converting into fuel. And of course, nobody eats algae. The only reason we don’t currently use algae to make biodiesel is that nobody has yet figured out how to do it.

In order to do this, scientists will primarily test multiple species of algae to find the ones that best produce the oil the scientists need to make fuel. Once they’ve zeroed in on the type of algae they’re going to use, the researchers will explore how best to turn that algae into high-performance diesel.

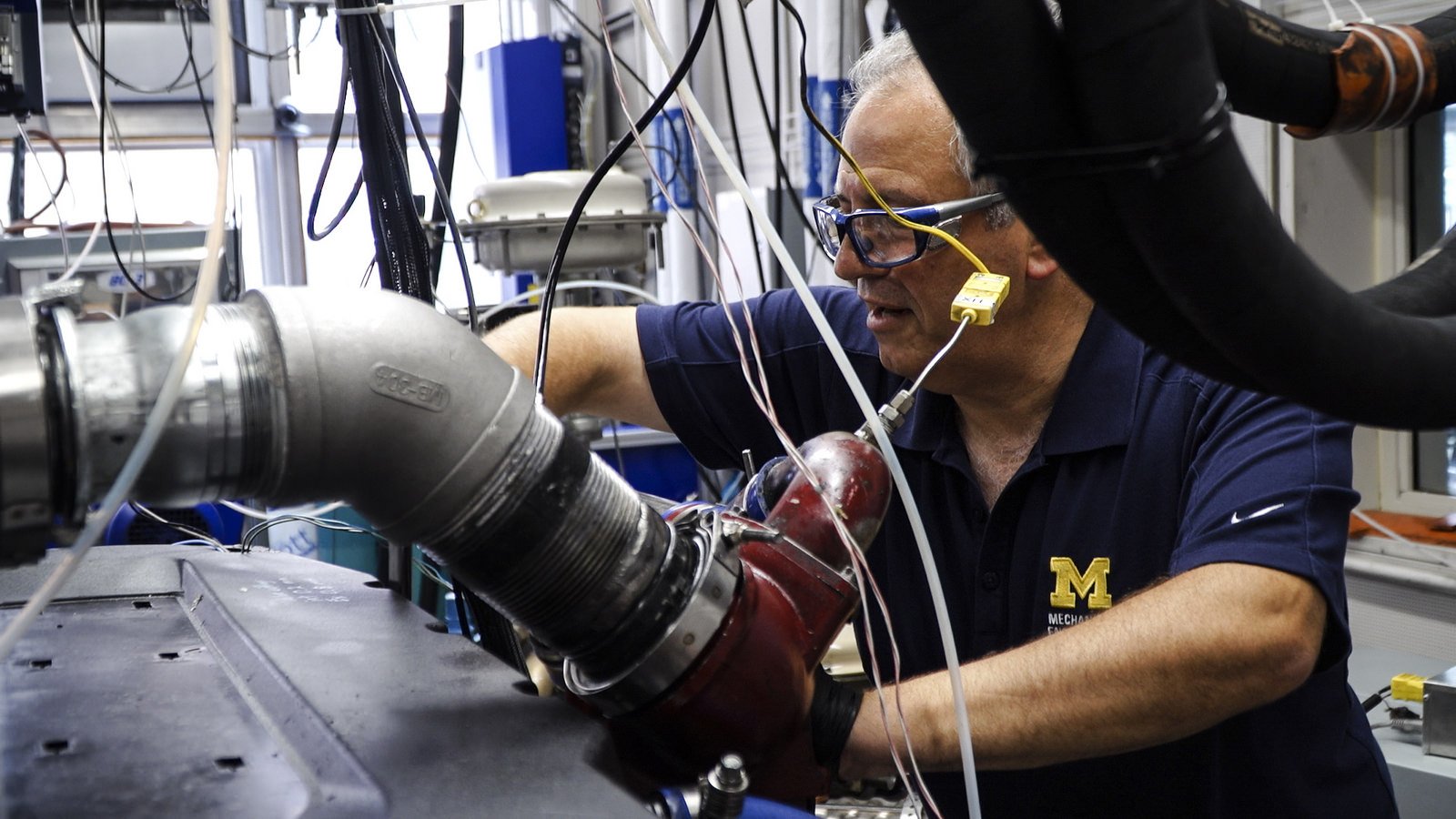

André Boehman, professor of mechanical engineering and director of U-M’s W.E. Lay Automotive Laboratory said, “It’s a project with big research questions. And it has the chance to do something that is very impactful—help us take a big step toward sustainability.”

The Department of Energy has said algae holds the potential to produce billions of gallons per year of renewable diesel, gasoline and jet fuels. And that contribution could prove crucial to meeting Renewable Fuel Standards. By 2022, 36 billion gallons of transportation fuels sold in the U.S. must come from blended sources. Only 15 million of those can come from corn-based ethanol, leaving a sizeable gap.

Bradley Cardinale, a biology professor and director of U-M’s Cooperative Institute for Great Lakes Research who is involved in the project said, “This is one of the first teams in the world to go all the way from designing sustainable biofuel feedstocks in outdoor ponds, to refining fuel so that it runs a diesel engine in a cleaner, more environmentally friendly way.”

The work includes determining combinations that lead to an optimal performance in areas such as fuel yield and stability. Researchers have previously found that a combination of algal species performs better than any single species, capitalizing on the individual strengths of each strain.

Cardinale said, “We’re not trying to fight against nature by designing one genetically superior strain of algae that can optimize all desired properties. We’re using the principles of ecological engineering to design a more comprehensive set of multi-species algal feedstocks that optimize several desired properties of algal biofuels at once.”

“The first principle of ecological engineering is that no single species can be good at everything. If we can simply find those species with the variety of desired properties, we could design tailor-made biofuels that optimize multiple properties simultaneously.”

In order to optimize the fuel’s combustion and emissions performance, researchers will look at both the biochemical properties of the algae as well as their chemical reactions in the controlled compression ignition combustion environment of the diesel engine. The biofuels will be tested in a light-duty vehicle engine and, once an optimal algae combination is determined, it will be tested in a Volvo truck engine.

Oil can be extracted from algae via mechanical means such as presses, or use of ultrasonic waves. Each approach forces oil to detach from the algae’s cell walls and be collected in a solvent. When that oil reacts with alcohol, the usable biodiesel product is separated out.

U-M’s research team uses an emerging technology called hydrothermal liquefaction to extract oil from the algae. It’s a process that simulates the pressures and temperatures that generate oil underground.

Boehman said, “Our overall objective is to demonstrate co-optimization of a fuel blendstock with greater than 60 percent greenhouse gas reduction. At the same time, we want to improve engine thermal efficiency beyond the baseline diesel engine.”

In addition to Boehman and Cardinale, the research team also includes Levi Thompson, a former U-M professor of chemical engineering who is now dean of engineering at the University of Delaware.