UNIST scientists have developed a tiny microsupercapacitor (MSC) that can be directly integrated with an electronic chip. As small as the width of a person’s fingerprint, this microsupercapacitor (MSC) has attracted significant attention as a novel technology to lead the era of the Internet of Things (IoT).

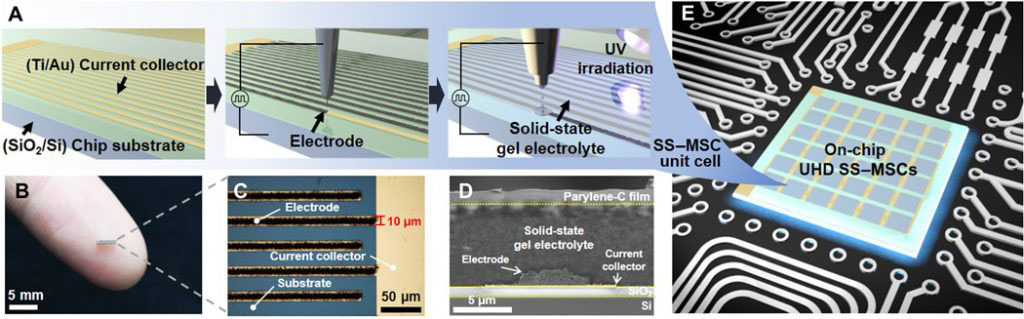

Through the study, Professor Sang-Young Lee and his research team in the School of Energy and Chemical Engineering at UNIST have unveiled a new class of ultrahigh areal number density solid-state MSCs (UHD SS–MSCs) on a chip via electrohydrodynamic (EHD) jet printing.

The heat produced in the manufacturing process may cause deterioration of the electrical characteristics of the supercapacitor. Hence, it is quite challenging to connect them directly to electronic components. Moreover, the manufacturing method that combines supercapacitors with electronic parts through the inkjet printing method has a disservice of lower exactness additionally.

Scientists solved this issue by using EHD jet printing, a high-resolution patterning technique in microelectronics. EHD jet printing uses the electrode and electrolyte for printing purposes similar to that of conventional inkjet printing, yet it can control printed liquid with an electric field.

Kwonhyung Lee (Combined M.S/Ph.D. of Energy and Chemical Engineering, UNIST), the first author of the study said, “We were able to produce up to 54.9 unit cells per square centimeter via electro-hydrodynamic jet printing technique, and thus the output of 65.9 volts (V) was achieved in the same area.”

Scientists also developed the 36 unit cells on a chip (area = 8.0 mm × 8.2 mm, 54.9 cells cm−2) and areal operating voltage (65.9 V cm−2) that lie far beyond those of previously reported MSCs fabricated by printing techniques. Besides, upon exposure to hot temperature (80°C), these cells maintained normal cyclic voltammetry (CV) profiles and thus have proven they can withstand excessive heat generated during the operation of an actual electronic component. Also, these batteries can provide customized power supplies, as they can be connected either in series or parallel.

Professor Lee said, “In this study, we have demonstrated on-chip UHD SS–MSCs fabricated via EHD jet printing. The on-chip UHD SS–MSCs presented here hold great promise as a new platform technology for miniaturized monolithic power sources with customized design and tunable electrochemical properties.”

This study has been supported through the Mid-career Researcher Supporting Program by the Ministry of Science and ICT (MSIT, Korea) and the Industry Technology Development Program funded by the Ministry of Trade, Industry, and Energy (MOTIE, Korea).

Journal Reference:

- Ultrahigh areal number density solid-state on-chip microsupercapacitors via Electrohydrodynamic Jet-Printing. DOI: 10.1126/sciadv.aaz1692