Scientists at the National University of Singapore (NUS) have built up a temperate and mechanically practical system to deliver graphene. The new procedure tends to the long-standing test of a proficient procedure for huge scale creation of graphene and makes ready for a maintainable union of the material.

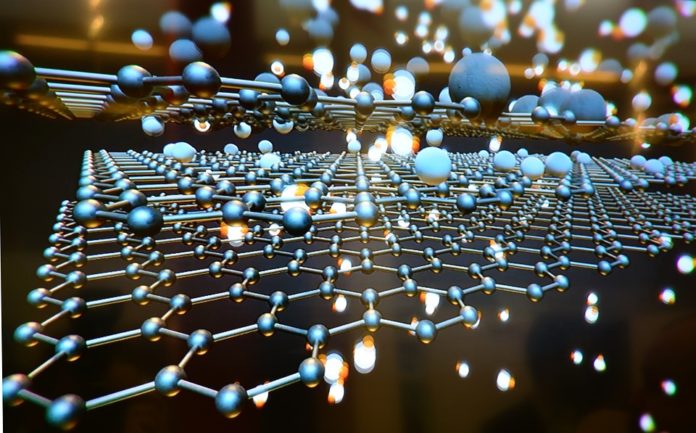

Graphene is a two-dimensional material with a honeycomb structure of just a single particle thick. Named as the material without bounds, graphene shows one of a kind electronic properties that can conceivably be utilized for an extensive variety of utilization, for example, touch screens, conductive inks and quick charging batteries. The trouble to create top-notch graphene reasonably on an extensive scale, in any case, keeps on posturing deterrent to its far-reaching appropriation by enterprises.

The regular strategy for creating graphene uses sound vitality or shearing powers to peel graphene layers from graphite and after that scattering the layers in a lot of natural dissolvable. As inadequate dissolvable causes, the graphene layers to reattach themselves once again into graphite, yielding one kilogram of graphene presently requires no less than one ton of natural dissolvable, making the technique exorbitant and ecologically threatening.

Scientists used around 50 times less dissolvable. This is accomplished by shedding pre-treated graphite under a very antacid condition to trigger flocculation, a procedure in which the graphene layers constantly group together to shape graphene slurry without increasing the volume of dissolvable. The technique additionally presents electrostatic awful powers between the graphene layers and keeps them from reattaching themselves.

The subsequent graphene slurry is effectively isolated into monolayers when required or put away for quite a long time. The slurry can likewise be utilized straightforwardly to 3D-print conductive graphene aerogels, an ultra-lightweight wipe like material that can be utilized to evacuate oil slick in the ocean.

Professor Loh Kian Ping from the Department of Chemistry at NUS Faculty of Science who is also the Head of 2D Materials Research at the NUS Centre for Advanced 2D Materials led the research. He said, “We have successfully demonstrated a unique exfoliation strategy for preparing high-quality graphene and its composites. Our technique, which produces a high yield of crystalline graphene in the form of a concentrated slurry with a significantly smaller volume of solvent, is an attractive solution for industries to carry out a large-scale synthesis of this promising material in a cost-effective and sustainable manner.”

The research is published in Nature Communications.