It is a fact that all the world’s living things are built out of combinations of just 20 amino acids. Is it possible to create a kit of only 20 fundamental parts that could be used to assemble all of the different technological products in the world?

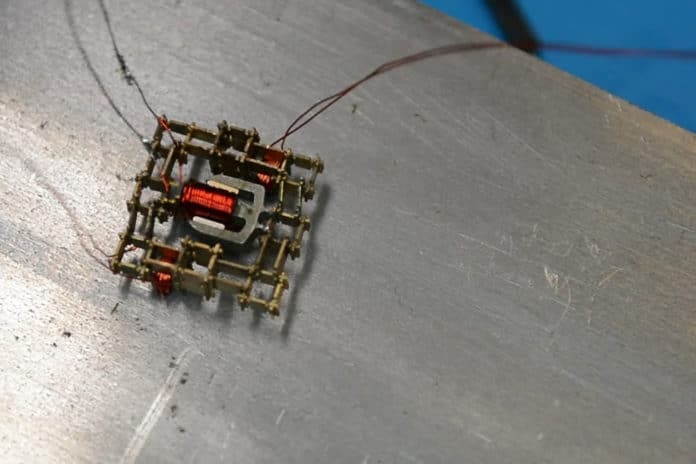

Now, MIT researchers have developed a “walking” motor that allows for robots which should be at once customizable, fast, and inexpensive. MIT Professor Neil Gershenfeld and MIT graduate student Will Langford came up with a set of five millimeter-scale components, all of which can be attached to each other by a standard connector.

It is made of five modular parts which include rigid and flexible types, along with electromagnetic parts, a coil, and a magnet. The team is next planning to make these out of still smaller basic part types.

Researchers then assembled these tiny parts into a novel kind of motor that can “walk” back and forth or make the gears of a more complicated machine move back and forth. These parts could also be assembled into hands for gripping, or legs for walking, as needed for a particular task, then later reassembled as those needs change. The motor is linked to a “micro-LEGO” that can be configured to do what you want with minimum confusion.

It is not only about the versatility, but the walking motor is powerful too. The initial motor has the ability to lift seven times its own weight, but if required, more components can be added for extra strength or to handle complex movements.

Don’t worry about the size of the project, the team has made nanometer-sized parts to make nanorobots, and meter-sized parts to make mega-robots. Earlier, specialized techniques were needed at each of these length scale extremes.

The new system is a significant step towards creating a standardized kit of parts that help assemble task-specific robots without needing to design new manufacturing bots every time.

“One emerging application is to make tiny robots that can work in confined spaces,” Gershenfeld says. Some of the devices assembled in this project, for example, are smaller than a penny yet can carry out useful tasks.

To build in the “brains,” Langford has added part types that contain millimeter-sized integrated circuits, along with a few other part types to take care of connecting electrical signals in three dimensions.

The new work “addresses assembling of sophisticated microrobotic systems from a small set of standard building blocks, which may revolutionize the field of microrobotics and open up numerous applications at small scales,” says Sergej Fatikow, head of the Division of Microrobotics and Control Engineering, at the University of Oldenburg, Germany.