Scientists at the University of Washington have devised and tested a 3D-printed metamaterial that can manipulate light with nanoscale accuracy.

Scientists designed principles, and experimental discoveries exhibit that it is conceivable to display and build metamaterial gadgets that can correctly control optical fields with high spatial goals in three dimensions. Even though the group picked a helical example — a spiral helix — for their visual component to focus light, their methodology could be utilized to plan optical components that control and focus light in different examples.

Devices with this level of accuracy control over light could be utilized not exclusively to scale down today’s optical elements, for example, focal points or retroreflectors, yet in addition to acknowledging new varieties. Moreover, designing visual fields in three dimensions could empower the formation of ultra-minimized profundity sensors for autonomous transportation, just as optical components for displays and sensors in virtual-or augmented reality headsets.

Corresponding author Arka Majumdar, a UW assistant professor of electrical and computer engineering and physics, said, “This reported device has no classical analog in refractive optics — the optics that we encounter in our day-to-day life. No one has made a device like this before with this set of capabilities.”

Scientists took a lesser-used approach in the optical metamaterials field to design the optical element: inverse design. Using inverse design, they began with the sort of visual field profile they needed to produce — eight focused points of light in a helical pattern — and planned a metamaterial surface that would create that pattern.

Majumdar said, “We do not always intuitively know the appropriate structure of an optical element given a specific functionality. This is where the inverse design comes in: You let the algorithm design the optics.”

Here, the team avoided this pitfall thanks to insight by Alan Zhan, lead author on the paper, who recently graduated the UW with a doctoral degree in physics. Zhan realized that the team could use a Mie scattering theory to design the optical element. Mie scattering describes how light waves of a particular wavelength are scattered by spheres or cylinders that are similar in size to the optical wavelength. Mie scattering theory explains how metallic nanoparticles in stained glass can give specific church windows their bold colors, and how other stained glass artifacts change color in different wavelengths of light, according to Zhan.

Zhan said, “Our implementation of Mie scattering theory is specific to certain shapes — spheres— which meant we had to incorporate those shapes into the design of the optical element. But, relying on Mie scattering theory significantly simplified the design and simulation process because we could make precise, exact calculations about the properties of light when it interacts with the optical element.”

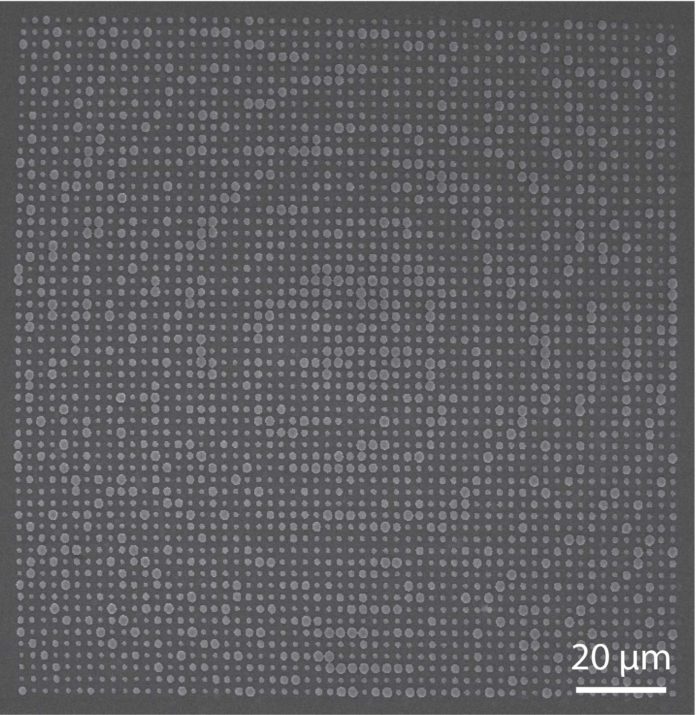

The device is covered in thousands of tiny spheres of different sizes, arranged in a periodic square lattice. Utilizing spheres simplified the design, and the team used a commercially accessible 3D printer to fabricate two prototype optical elements — the larger of the two with sides naturally 0.02 centimeters long — at the Washington Nanofabrication Facility on the UW campus. The visual elements were 3D-printed out of a bright epoxy on glass surfaces. One component was intended to concentrate light at 1,550 nanometers, the other at 3,000 nanometers.

Scientists visualized the optical elements under a microscope lens to see how well they executed as designed— focusing light of either 1,550 or 3,000 nanometers at eight specific points along with a 3D helical pattern. Under the microscope, most focused points of light were at the positions anticipated by the group’s theoretical simulations. For instance, for the 1,550-nanometer wavelength gadget, six of eight focal points were in the predicted location. The remaining two showed only minor deviations.

Majumdar said, “Now that we’ve shown the basic design principles work, there are lots of directions we can go with this level of precision in fabrication. One particularly promising direction is to progress beyond a single-surface to create a true-volume, 3D metamaterial.”

“3D-printing allows us to create a stack of these surfaces, which was not possible before.”

The study is published in the journal of Science Advances.