Scientists at the European Space Agency say they have found a way to produce oxygen out of simulated moondust. The samples returned from the lunar surface is found to contain 40–45% percent oxygen by weight.

According to scientists, this could be hugely useful for future lunar settlers, both for breathing and in the local production of rocket fuel.

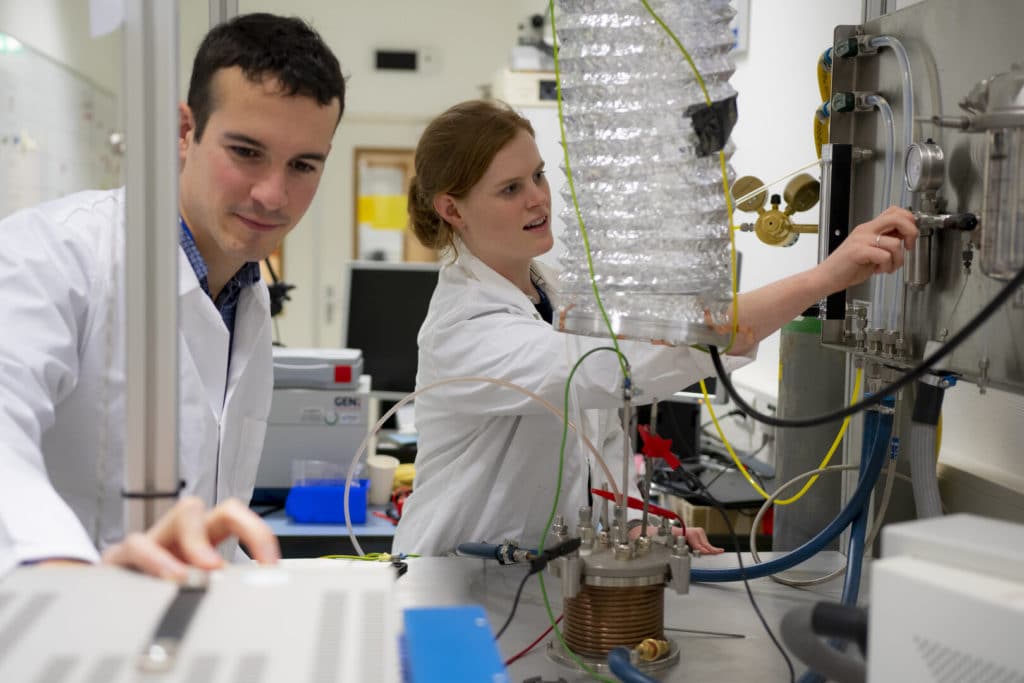

Now, scientists are working on a system that can extract breathable oxygen from simulated samples of moon dust. A prototype oxygen plant has been set up in the Materials and Electrical Components Laboratory of the European Space Research and Technology Centre, ESTEC, based in Noordwijk in the Netherlands.

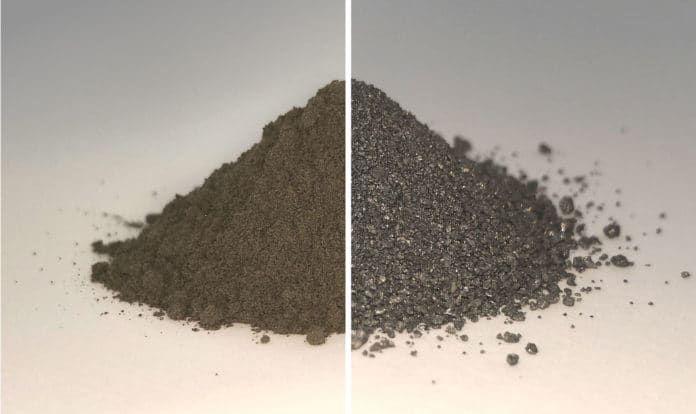

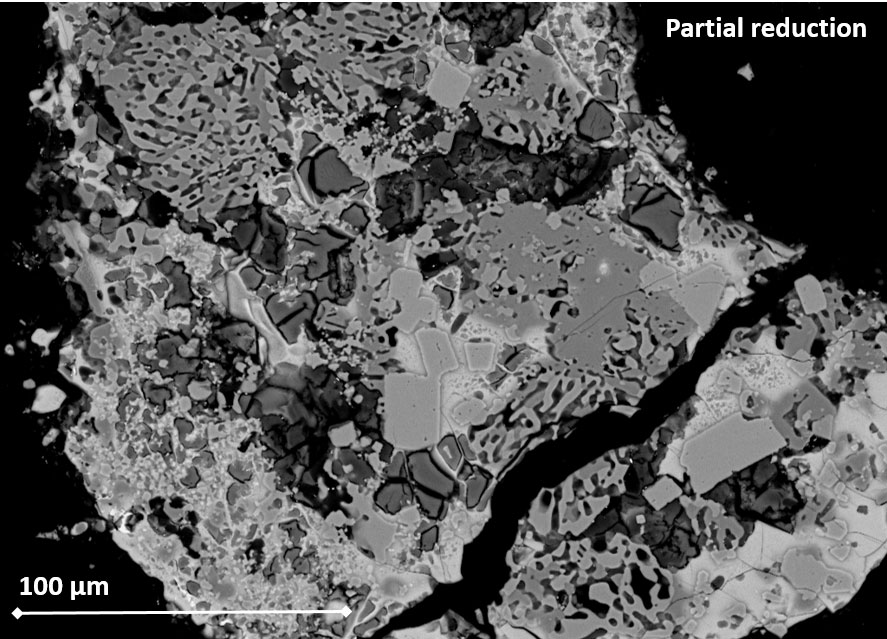

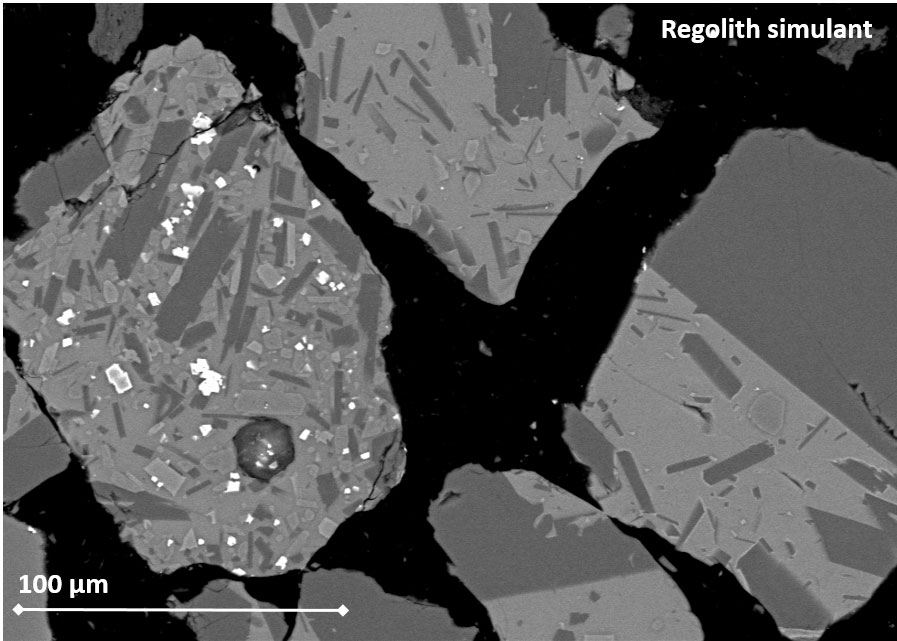

To extract the oxygen, their prototype system uses a method called molten salt electrolysis, involving placing lunar dust, also called regolith in a metal basket with molten calcium chloride salt to serve as an electrolyte, heated to 950°C. At this temperature, the regolith remains solid.

Passing a current through it causes the oxygen to be extracted from the regolith and migrate across the salt to be collected at an anode. There is an additional benefit of this process that it also converts the regolith into usable metal alloys.

This process was developed by UK company Metalysis, where the process produces oxygen is an unwanted by-product and is instead released as carbon dioxide and carbon monoxide. Thus, scientists had to redesign the system capture and measure any oxygen extracted from the samples. As it stands, the system is venting oxygen into an exhaust pipe, but future versions will capture and store this oxygen for the long term.

ESA research fellow Alexandre Meurisse said, “The production process leaves behind a tangle of different metals. And this is another useful line of research, to see what are the most useful alloys that could be produced from them, and what kind of applications could they be put to.”

Scientists are now focusing on designing a ‘pilot plant’ that could operate sustainably on the Moon.

Tommaso Ghidini, Head of ESA’s Structures, Mechanisms and Materials Division, said, “ESA and NASA are heading back to the Moon with crewed missions, this time to stay. Accordingly, we’re shifting our engineering approach to systematic use of lunar resources in-situ. We are working with our colleagues in the Human and Robotics Exploration Directorate, European industry and academia to provide top class scientific approaches and key enabling technologies like this one, towards a sustained human presence on the Moon and maybe one day Mars.”