Hydrogen has the potential to be one of the best alternatives to fossil fuels with net-zero emissions. However, the use of freshwater to produce hydrogen on a large scale is ultimately a threat to the survival of life as it puts strain on the limited freshwater reserves.

Seawater, an unlimited source, can be an alternative, but its salt-rich nature causes corrosion and introduces several competing reactions, hindering its use. The required desalination of seawater prior to use in an electrolyzer is not only energy-intensive and costly but also leaves behind a carbon footprint.

To overcome these, RMIT University researchers have developed a cheaper and more energy-efficient way to make green hydrogen directly from seawater. The new method splits the seawater directly into hydrogen and oxygen – skipping the need for desalination and its associated cost, energy consumption, and carbon emissions.

“We know hydrogen has immense potential as a clean energy source, particularly for the many industries that can’t easily switch over to be powered by renewables,” said lead researcher Dr. Nasir Mahmood, a Vice-Chancellor’s Senior Research Fellow at RMIT. “But to be truly sustainable, the hydrogen we use must be 100% carbon-free across the entire product life cycle and must not cut into the world’s precious freshwater reserves.”

“Our method to produce hydrogen straight from seawater is simple, scalable, and far more cost-effective than any green hydrogen approach currently in the market. With further development, we hope this could advance the establishment of a thriving green hydrogen industry in Australia.”

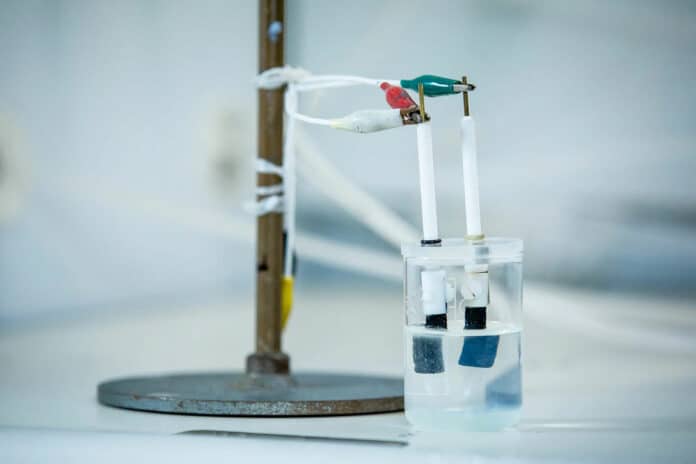

To make green hydrogen, an electrolyzer is used to send an electric current through water to split it into its component elements of hydrogen and oxygen. These electrolyzers currently use expensive catalysts and consume a lot of energy and water. It can take about nine liters to make one kilogram of hydrogen. Besides, they have a bulk output of toxic chlorine, according to RMIT researchers.

“The biggest hurdle with using seawater is the chlorine, which can be produced as a by-product,” said Mahmood. “If we were to meet the world’s hydrogen needs without solving this issue first, we’d produce 240 million tons per year of chlorine each year – which is three to four times what the world needs in chlorine. There’s no point replacing hydrogen made by fossil fuels with hydrogen production that could be damaging our environment in a different way. Our process not only omits carbon dioxide but also has no chlorine production.”

The new approach devised by the RMIT team uses a special type of catalyst developed to work specifically with seawater. The new highly efficient, stable catalysts take very little energy to run and can be used at room temperature.

Unlike most other experimental catalysts that are complex and hard to scale, the new approach focused on changing the internal chemistry of the catalysts through a simple method. This makes them relatively easy to produce at large scale, so they can be readily synthesized at industrial scales.

The researchers say their technology promises to significantly bring down the cost of electrolyzers to make it competitive with fossil fuel-sourced hydrogen. The next step in the research is the development of a prototype electrolyzer that combines a series of catalysts to produce large quantities of hydrogen. They are also working with industry partners to develop aspects of this technology.

Journal reference:

- Suraj Loomba, Muhammad Waqas Khan, Muhammad Haris, Seyed Mahdi Mousavi, Ali Zavabeti, Kai Xu, Anton Tadich, Lars Thomsen, Christopher F. McConville, Yongxiang Li, Sumeet Walia, Nasir Mahmood. Nitrogen-Doped Porous Nickel Molybdenum Phosphide Sheets for Efficient Seawater Splitting. Small, 2023; DOI: 10.1002/smll.202207310