An interdisciplinary MIT team has developed FibeRobo- a programmable, actuating fiber that could someday be used in textiles. This thermally-actuated liquid crystal elastomer (LCE) fiber could enable silent and responsive interactions with shape-changing, fiber-based interfaces.

Fiberobo contracts in response to an increase in temperature, then self-reverses when the temperature decreases, without any embedded sensors or other complex components. It can be coupled with a conductive thread, an element when an electric current is heated. In this sense, the fibers are electrically actuated, giving the user digital control over the shape of a textile. A fabric might, for example, alter its structure in response to any digital data, including heart rate sensor measurements.

The drawbacks of the current shape-changing fibers have mainly prohibited their use in textiles outside of experimental settings.

A single fiber, a shape-changing alloy, seldom ceases functioning after a few actions, only contracts by roughly 5%, and cannot self-reverse. Another is a pneumatically powered device, a McKibben actuator, which needs an air compressor to operate.

The MIT researchers’ project aimed to create a fiber that could function silently, undergo significant morphological changes and work with standard textile production processes. They employed a liquid crystal elastomer (LCE) to do this.

A liquid crystal comprises a group of molecules that flow like liquids yet stack into periodic crystal arrangements when given time to settle. The scientists integrate these crystal structures into an elastic network called an elastomer, which resembles a rubber band.

The fiber contracts as the LCE material heats up because the crystal molecules misalign and pull the elastomer network together. According to Forman, when the heat is removed, the molecules realign, and the material stretches to its initial length.

The ultimate characteristics of the fiber, such as its thickness and the temperature at which it actuates, may be precisely controlled by the researchers by carefully combining chemicals to create the LCE. They developed a method of preparation that yields LCE fiber that is acceptable for wearable fabrics and can actuate at temperatures that are safe for human skin. This was not possible for scientists to achieve with other LCE fibers.

In their study, scientists built a machine using 3D-printed and laser-cut parts and basic electronics to overcome the fabrication challenges. They begin by heating the thick and dense LCE resin and then slowly squeezing through a nozzle like a glue gun.

After extracting the resin, it is carefully cured with UV rays on both sides of the fiber as it progressively extrudes.

The material will separate and flow out of the machine if the light is too faint, but clumps may form if the light is too bright, resulting in rough strands.

After that, the fiber is coated with oil to make it slippery and is once more cured under intense UV radiation to produce a robust and smooth yarn. The material is gathered onto a top spool and coated with powder to facilitate its easy insertion into textile manufacturing machinery.

The entire process, from chemical synthesis to completed spool, takes about one day and yields roughly one kilometer of usable fiber.

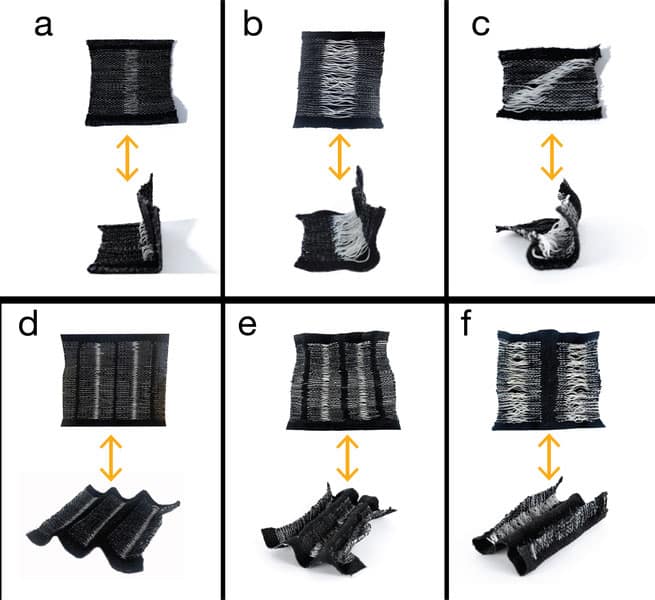

As scientists reported, FibeRobo can contract up to 40 percent without bending actuate at skin-safe temperatures. It can be produced with a low-cost setup for 20 cents per meter, which is about 60 times cheaper than commercially available shape-changing fibers.

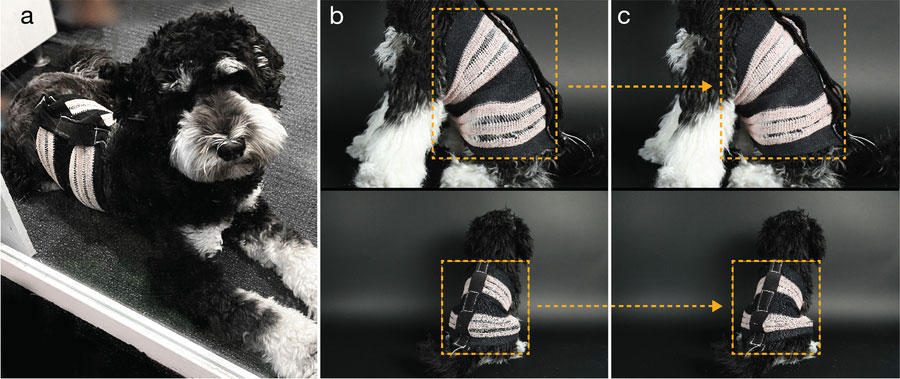

Using the Fiberobo, scientists created a jacket for a dog named Professor. The jacket would ” hug ” the dog when it received a Bluetooth signal from Forman’s smartphone. When a dog’s owner is away, compression jackets are frequently used to help ease their separation anxiety.

Lining Yao, the Cooper-Siegel Associate Professor of Human-Computer Interaction at Carnegie Mellon University, who was not involved with this work, said, “LCE fibers come to life when integrated into functional textiles. It is particularly fascinating to observe how the authors have explored creative textile designs using a variety of weaving and knitting patterns.”

Journal Reference:

- Jack Forman, Ozgun Kilic Afsar, Sarah Nicita et al. FibeRobo: Fabricating 4D Fiber Interfaces by Continuous Drawing of Temperature Tunable Liquid Crystal Elastomers. ACM Symposium on User Interface Software and Technology. DOI: 10.1145/3586183.3606732