An international team of researchers has engineered a new family of enzymes that could pave the way towards the conversion of plant waste into high-demand sustainable products, including nylon, chemicals, and plastics.

The newly developed family of enzymes is active on the building blocks lignin, a complex organic polymer that can be found in the cell walls of many plants. It is used for defense, structure, and nutrient water transport. Because of its prevalence in plant tissues, lignin is the largest reservoir of renewable, aromatic carbon found in nature.

“We have taken a naturally occurring enzyme and engineered it to perform a key reaction in the breakdown of one of the toughest natural plant polymers,” said Professor McGeehan Director of the Centre for Enzyme Innovation in the School of Biological Sciences at Portsmouth.

Scientists have been trying for decades to find a way to break down lignin efficiency. So, a research team from the University of Portsmouth found a way to release a major obstacle in the process of breaking down lignin to its basic chemicals. The results provide a way to build new materials and chemicals such as nylon, bioplastics, and even carbon fiber, from what has previously been a waste product.

The new research also offers additional environmental benefits. Making products from lignin can reduce reliance on oil to make everyday products. Besides, it provides an attractive alternative to burning it, helping to reduce CO2 emissions.

“It’s an amazing material,” said Professor McGeehan. “Cellulose and lignin are among the most abundant biopolymers on earth. The success of plants is largely due to the clever mixture of these polymers to create lignocellulose, a material that is challenging to digest.“

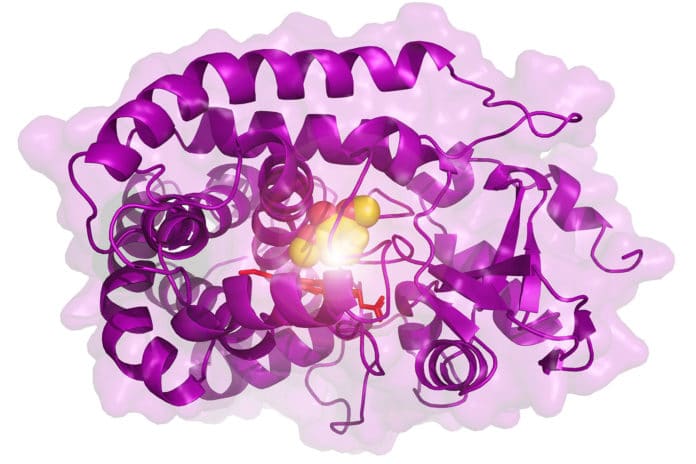

Previously developed enzymes could only work on one building block of lignin, which made the breakdown process inefficient. Using advanced 3D structural and biochemical techniques, the team managed to alter the shape of the enzyme to accommodate multiple building blocks.

Also, the newly-discovered enzyme is a class of cytochrome P450, and it is classified as ‘promiscuous,’ meaning it can work on a wide range of molecules. The new cytochrome can degrade many different lignin-based substrates, making it possible to be engineered to be a specialist for a specific molecule.

“We used X-ray crystallography at the Diamond Light Source synchrotron to solve ten enzyme structures in complex with lignin building blocks,” explained study co-author Dan Hinchen. “This gave us the blueprint to engineer an enzyme to work on new molecules. Our colleagues were then able to transfer the DNA code for this new enzyme into an industrial strain of bacteria, extending its capability to perform multiple reactions.”

“We now have proof-of-principle that we can successfully engineer this class of enzymes to tackle some of the most challenging lignin-based molecules and we will continue to develop biological tools that can convert waste into valuable and sustainable materials,” added Professor McGeehan.

The research team was made up of an international team of experts in structural biology, biochemistry, quantum chemistry and synthetic biology at the Universities of Portsmouth, Montana State, Georgia, Kentucky and California, and two US national laboratories, NREL and Oak Ridge.

The study is published in the journal Proceedings of the National Academy of Sciences.