The present 3-D printers have a determination of 600 dots for each inch. This means they could pack a billion modest shapes of various materials into only 1.67 cubic inches.

Controlling the microstructure of printed objects gives designers similar control of the object’s physical properties. For example, their density or strength or how they disfigure when stressed. Evaluating the physical effects would be prohibitively time-consuming.

So, clusters can then be represented as building blocks for larger printable objects. This means it takes the benefit of physical measurements at the microscopic scale while enabling computationally efficient evaluation of macroscopic designs.

Bo Zhu, a postdoc at CSAIL, said, “Conventionally, people design 3-D prints manually. But when you want to have some higher-level goal. For instance, you want to design a chair with maximum stiffness or design some functional soft [robotic] gripper. At such an instant, intuition or experience is maybe not enough. Topology optimization, which is the focus of our paper, incorporates the physics and simulation in the design loop. The problem for current topology optimization is a gap between hardware and software capabilities. Our algorithm fills that gap.”

Scientists started their work by defining a space of physical properties of the microstructure of printing that assumes a particular location. For example, there are three strands: First, describe its deformation in the direction of an applied force. Second describes its deformation in directions perpendicular to an applied force. And the third describes its response to shear.

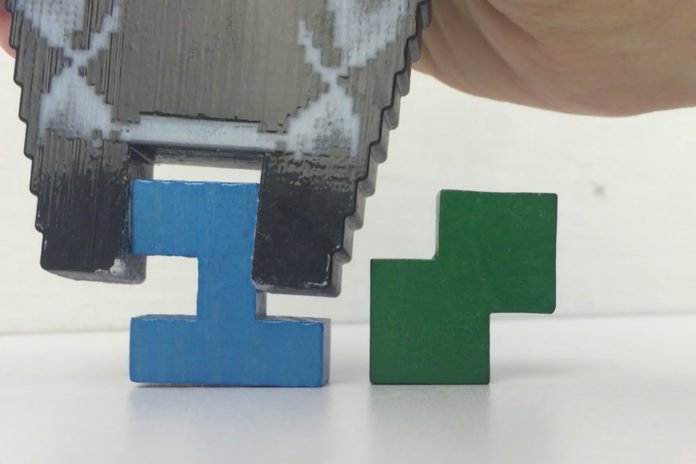

All three strands initialize a three-dimensional space. In 3-D printing, the microscopic cubes assembled from an object are called voxels, which are 3D analog of pixels in a digital image. Through these building blocks, scientists assemble larger printable objects.

During the study, scientists used clusters of size 16, 32, and 64 voxels to a face. For a given arrangement of printable materials, they arbitrarily create bunches that consolidate those materials in various ways. For example, a square of material at the group’s middle, an outskirt of empty voxels around that square, material B at the corners, or something like that. The bunches must be printable, in any case. They wouldn’t be conceivable to print a group that incorporated a solid shape of empty voxels with a little 3D square of material gliding at its middle.

Scientist’s algorithm successfully investigates the whole space of properties. The results become a cloud point that characterizes the space of printable groups.

The following stage is to compute a capacity called the level set, which portrays the state of the point cloud. Through this, scientists can mathematically determine whether a cluster with a particular combination of properties is printable or not.

And the final step is to optimize the object to be printed using software custom-developed by the researchers. It will result in specifications of material properties for tens or even hundreds of thousands of printable clusters.

An assistant professor, Bernd Bickel said, “The design and discovery of structures to produce materials and objects with exactly specified functional properties is central for a large number of applications where mechanical properties are important, such as in the automotive or aerospace industries.”

“Due to the complexity of these structures, which, in the case of 3-D printing, can consist of more than a trillion material droplets, exploring them manually is intractable.”

“Instead of working directly on the scale of individual droplets, they first pre-compute the behavior of small structures and put it in a database. Leveraging this knowledge, they can perform the actual optimization on a coarser level, allowing them to very efficiently generate high-resolution printable structures with more than a trillion elements, even with a regular computer. This opens up exciting new avenues for designing and optimizing structures at a resolution out of reach.”