Conventional polymer materials soften or even flow above their glass transition temperatures. Such intrinsic thermal properties prevent the polymers from various applications at elevated temperatures.

As a solution, scientists from the Hokkaido University have developed a hydrogel that does the opposite of what polymer-based materials, like plastic bottles, normally do: their material hardens when heated and softens when cooled.

The material was developed by getting inspired by how proteins remain stable inside organisms that survive within extreme-heat environments, like hot springs and deep-sea thermal vents.

Typically, heat “denatures” proteins, changing their structure and breaking their bonds. Be that as it may, the proteins inside thermophiles stay stable with heat thanks to electrostatic interactions, for example, ionic bonds.

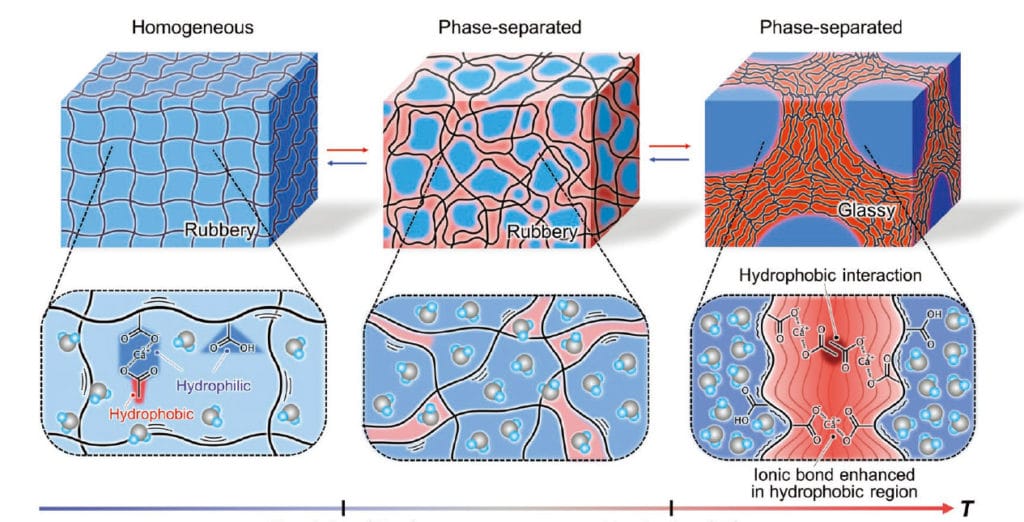

Scientists primarily developed a gel composed of polyelectrolyte poly (acrylic acid) (PAAc), which was then immersed in a calcium acetate aqueous solution. PAAc on its acts like any other polymer-based material and softens when heated.

When calcium acetate is added, PAAc’s side residues interact with the calcium acetate molecules, in a way similar to what happens inside thermophile proteins, causing PAAc to act very differently.

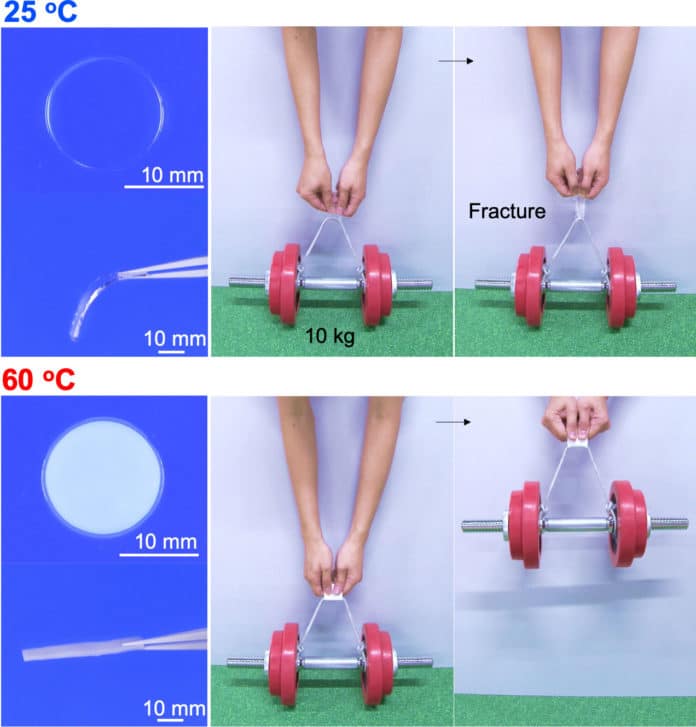

Scientists found that the gel separates into a polymer dense “phase” and a sparse polymer one as the temperature rises. When it reaches a critical temperature, in this case, around 60°C, the dense phase undergoes significant dehydration, which strengthens ionic bonds and hydrophobic interactions between polymer molecules. This causes the material to rapidly transform from a soft, transparent hydrogel to rigid, opaque plastic.

The heated material was 1,800 times stiffer, 80 times stronger, and 20 times tougher than the original hydrogel. The soft-to-rigid switching was completely reversible by alternately heating and cooling the material. Moreover, scientists could fine-tune the switching temperature by adjusting the concentration of the ingredients.

Takayuki Nonoyama of Hokkaido University said, “Clothing made from similar fabric could be used to protect people during a traffic or sports-related accidents, for example. Our material could also be used as a heat-absorbent window coating to keep indoor environments cooler.”

“This polymer gel can be easily made from versatile, inexpensive, and non-toxic raw materials that are commonly found in daily life. Specifically, the polyacrylic acids are used in disposable diapers, and calcium acetates are used in food additives. Our study contributes to basic research on new temperature-responsive polymers, and applied research on temperature-responsive smart materials.”

The study is published in Advanced Materials.