Researchers at the National Institute of Standards and Technology (NIST), in collaboration with researchers from Georgia Tech, have developed the first-of-its-kind chip-scale version of an atomic beam clock. The new miniature atomic clock could offer better timing over the span of weeks and months compared with current systems.

Atomic clocks have been around since the 1950s in one form or another. These are the most precise and accurate timekeeping devices that rely on the vibrations of atoms to measure time.

They take many forms, but the oldest and one of the most prominent designs is built using atomic beams. These clocks work by sending a beam of atoms through a vacuum chamber, measuring their ticking rate. Other clocks can be compared to atomic beam clocks using the atom’s precise ticking rate and adjusted to match their timing.

Beam clocks are precise, stable, and accurate, but they’re currently not the most portable. The vacuum chambers where the atoms travel are key to the success of these clocks, but they are bulky in part due to the size of the microwave cavity used to probe the atomic ticking. The vacuum chamber for NIST-7, the last beam clock used for the primary frequency standard in the United States, was more than 2.5 meters or 8 feet long. Smaller commercial clocks of the size of a briefcase are common, but they still require a significant amount of power to run.

In 2001, NIST developed chip-scale atomic clocks (CSACs) that consume very little power and can run on batteries to provide timing in critical situations where GPS can’t reach. However, the clocks’ timekeeping tends to drift when temperatures change, and the gas surrounding the atoms degrades. That’s a frequent concern, given CSACs tend to be used in applications like underwater oil and gas exploration, military navigation, and even telecommunications.

“What if we could combine the best aspects of these two systems?” said William McGehee, a physicist at NIST.

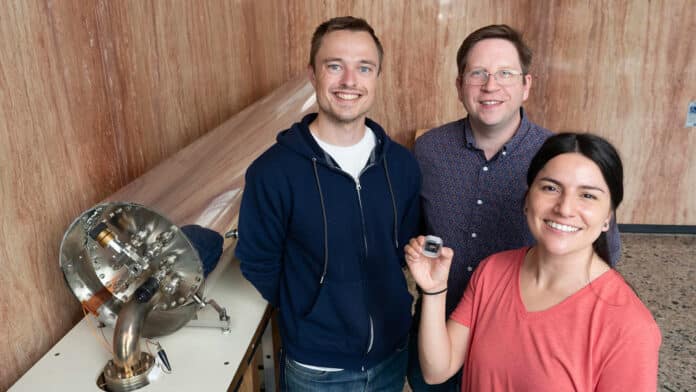

Researchers used microfabrication techniques learned from the CSACs to fabricate a chip-scale atomic beam device made from a stack of etched silicon and glass layers. This device, about the size of a postage stamp, is a highly miniaturized version of the chambers that have been used in atomic beam clocks like NIST-7.

The device contains one chamber of a small pill of rubidium. The chamber heats up, releasing a stream of rubidium atoms through micro capillaries, channels only 100 micrometers wide. These tiny channels connect to another chamber with materials that can collect individual gas molecules called non-evaporable getters (NEGs). The NEGs pull the rubidium atoms along and collect them, keeping the vacuum in the microcapillaries clean. Tiny graphite rods also help collect stray atoms that could affect measurements.

Currently, the chip-scale beam device is a prototype for a miniature atomic beam clock, with initial tests showing performance “at a level slightly worse than existing CSACs.” But the team still sees a path toward improved stability. They hope to push their precision by a factor of 10 and exceed the stability of present CSACs by 100 times over weekly periods.

Journal reference:

- Gabriela D. Martinez, Chao Li, Alexander Staron, John Kitching, Chandra Raman, and William R. McGehee. A chip-scale atomic beam clock. Nature Communications, 2023; DOI: 10.1038/s41467-023-39166-1