Using high-speed imaging, a new study by the University of Leeds has provided a fresh insight into the complex way droplets behave when they interact.

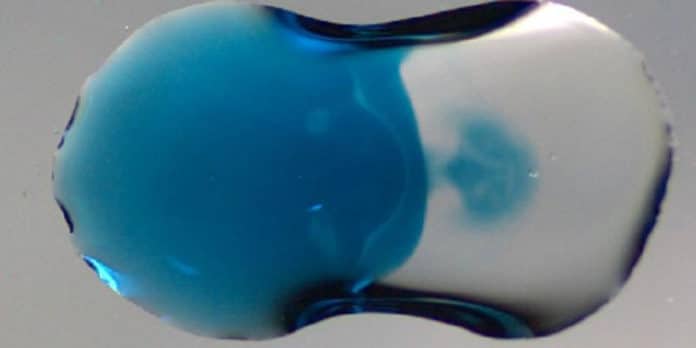

Scientists used one of the color cameras and shot up to 25,000 frames a second to capture the moment two droplets of liquid come together. This opens up research into new applications for 3D printing.

The cameras are positioned below the droplets and the other to the side. The synchronized system was able to record the moment one of the droplets passed over the other, creating a surface jet that formed less than 15 milliseconds – 15 thousandths of a second – after they coalesced.

Thomas Sykes, a Ph.D. researcher at the University of Leeds and lead author of a paper about the study, said, “The chemistry behind emerging 3D-printing technologies involves having chemicals deposited onto a surface. We often need those chemicals to be positioned in a highly specific way; for example, we may want the droplets to lie side by side or for one droplet to rest on another.”

“On other occasions, we want them to mix completely to produce the desired reaction to 3D print more complex structures.”

Scientists observed what was happening both on the surface and inside the droplets to make a better assessment of mixing.

Dr. Alfonso Castrejón-Pita, an Associate Professor and co-author of the study based at the University of Oxford, added: “In the past, there have been instances when two droplets impact and you were left wondering whether they have mixed or has one droplet just passed over the other. Having two cameras record the droplet interaction from different viewpoints answers that question.”

Scientists hope to extend the range and type of products that can be manufactured by 3D printing, for example, high-precision “scaffolds” for tissue engineering in the laboratory, on which human tissue can be grown.

But significant advances in the technology require a clearer understanding of the way chemicals react when a 3D printer deposits them.

Dr. Mark Wilson, an Associate Professor at Leeds and lead supervisor of the project, said: “The imaging techniques developed have opened up a new window on droplet technology.”

“We were able to expose the internal flows, while imaging at a sufficient speed to capture the fast dynamics. This experimental setup allows us to visualize how, by altering the surface tension of the droplets, we can alter their behavior.”

The findings have been published in the journal Physical Review Fluids.