Fatigue in metals involves gradual failure through incremental propagation of cracks under repetitive mechanical load. Fatigue in structural applications accounts for up to 90% of in-service failures. Fatigue prevention relies on implementing large safety factors and inefficient overdesign.

For the first time, scientists have seen metal fragments break, then recombine naturally, challenging tenets of conventional science in the process. Suppose the recently discovered phenomena can be harnessed. In that case, it may lead to an engineering revolution in which self-healing engines, bridges, and aircraft repair wear-and-tear damage and become safer and more durable.

Sandia materials scientist Brad Boyce said, “This was stunning to watch first-hand.”

“What we have confirmed is that metals have their own intrinsic, natural ability to heal themselves, at least in the case of fatigue damage at the nanoscale.”

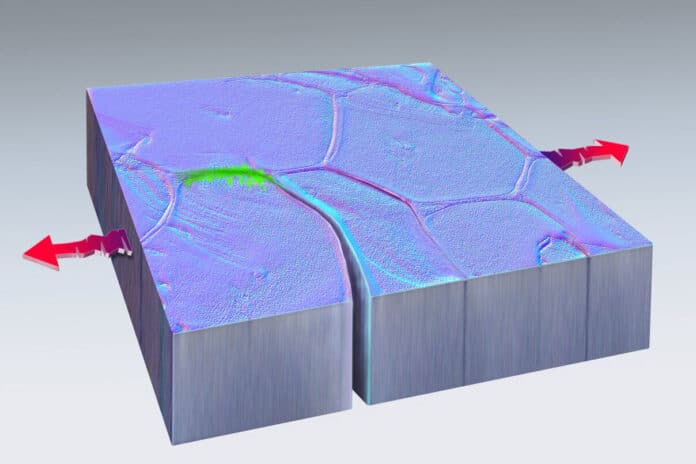

Scientists saw the early development of nanoscale fatigue cracks, and as expected, the cracks advance, deflect and arrest local microstructural barriers. Unexpectedly, cracks were also seen to close by a process known as crack flank cold welding brought on by a convergence of local stress state and grain boundary movement.

The fissure scientists saw disappear was one of these tiny but consequential fractures — measured in nanometers.

In 2013, Michael Demkowicz from Texas A&M found- based on computer simulations- under certain conditions, metal should be able to weld shut cracks formed by wear and tear.

When the discovery was made, Chris Barr, who now works for the Department of Energy’s Office of Nuclear Energy, and Khalid Hattar, an associate professor at the University of Tennessee in Knoxville, were in charge of the experiment at Sandia. They intended to assess how cracks originated and propagated through a nanoscale platinum piece using a specialized electron microscope technique they had devised to continually pull on the ends of the metal at a rate of 200 times per second.

Surprisingly, the damage reversed course 40 minutes into the trial. No sign of the prior damage was left after one end of the crack fused back together, seemingly following its path. The crack gradually regrew in a different direction.

Hattar said, “It is an unprecedented insight.”

Prof. Demkowicz then recreated the experiment on a computer model- offering evidence that the phenomenon observed was the same one he had theorized years earlier.

Boyce said, “The extent to which these findings are generalizable will likely become a subject of extensive research. We show this happening in nanocrystalline metals in a vacuum. But we don’t know if this can also be induced in conventional metals in air.”

Journal Reference:

- Barr, C.M., Duong, T., Bufford, D.C. et al. Autonomous healing of fatigue cracks via cold welding. Nature (2023). DOI: 10.1038/s41586-023-06223-0