In a new study, Yale scientists have finally found the answer to a centuries-old mystery of how glasses transition into very resilient states. Precisely what occurs amid this glass transition for all types of glass has confounded specialists for a long time. Additionally, how the properties of the subsequent glasses rely upon the transitions remain subtle.

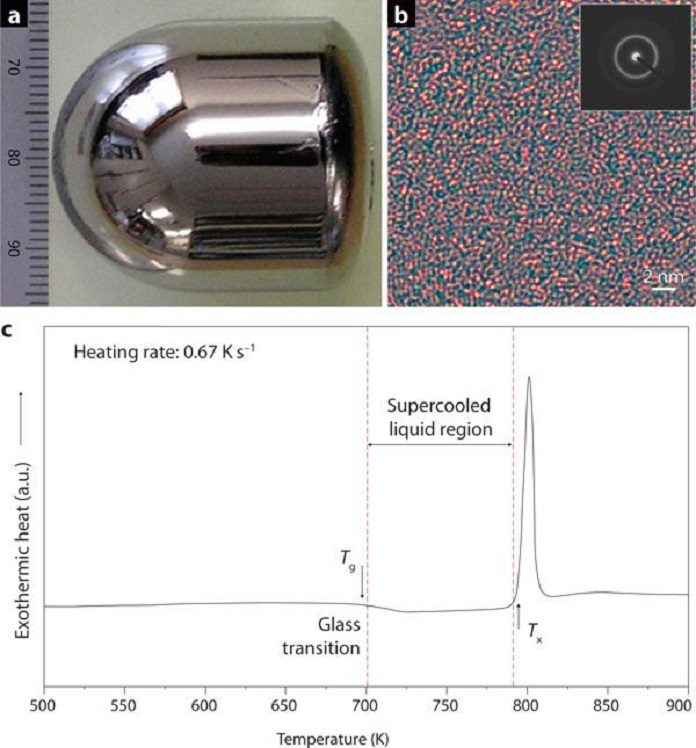

Bulk metallic glasses (BMGs) are a moderately new class of materials produced using complex, multicomponent amalgams. They have the malleable flexibility of plastics at high temperatures yet the qualities of metals at room temperature.

BMGs owe their properties to their exceptional nuclear structures: When metallic glasses cool from a fluid to a solid, their molecules settle into an irregular plan and don’t crystallize the way in which customary metals do.

Scientists have figured out that the key piece of these puzzles is in a non-standard quantity known as the fictive temperature. As opposed to concentrating on warm, the fictive temperature centers around the structure of the material, which is consistently changing in glasses amid the progress from fluid to strong and the other way around.

Jan Schroers, professor of mechanical engineering, said, “Every time you change the temperature a little bit, the entire structure — every atom inside — changes its position. That doesn’t happen at all in more conventional materials.”

Co-author Eran Bouchbinder, professor of chemical and biological physics at the Weizmann Institute of Science in Israel said, “We noticed that the thing the ordinary temperature does — the thermal or kinetic energy — is less relevant. Whereas the structural changes — the fictive temperature — that’s very important.”

Concentrating on the fictive temperature rather than traditional temperature, the specialists built up a methodology that enables them to control the structure of the material as it changes into a strong frame. This can be precisely tuned in the lab.

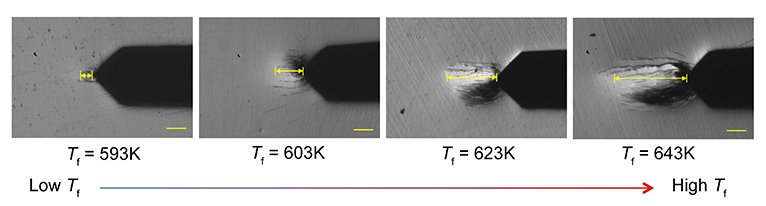

Jittisa Ketkaew, a graduate student who led the experiments, said, “The ability to change a brittle glass to one that’s ductile and able to easily bend without breaking almost seems like alchemy. Most surprising for the researchers, gradually changing fictive temperatures brought about dramatic changes in fracture toughness. We repeated and refined experiments over and over until we accepted the outcome and ultimately developed a theoretical description.”

“Our findings suggest that you can make any metallic glass ductile or brittle simply by controlling the fictive temperature.”

The discoveries interact with a transformational change in the field and could go far to make the handling of BMGs substantially more dependable. Having the capacity to reliably accomplish a BMG with more prominent resilience— known as “fracture toughness” — is basic to the across-the-board utilization of BMGs in stack-bearing applications.

While this means that all brittle glasses can be made ductile in theory, not all BMGs can easily retain the ductile state when they cool to room temperature. Magnesium and iron-based glasses, for instance, require very high cooling rates that are currently difficult to realize.

A study published Aug. 16 in Nature Communications provides critical information.